How can different gases impact the efficiency of laser cutting? This article explores the performance of air, oxygen, and nitrogen as cutting gases, comparing their effects on various metals. You’ll discover which gas offers the best speed, quality, and cost-effectiveness for specific applications. By understanding these differences, you can optimize your laser cutting process to improve production outcomes and reduce costs.

Air, the vital “gas of life” we breathe daily, is composed of 78% nitrogen, 21% oxygen, 0.94% rare gases (such as helium, neon, argon, krypton, and xenon), 0.03% carbon dioxide, and 0.03% other substances (such as water vapor and impurities).

Now, let’s delve into the benefits of air cutting in the laser cutting process.

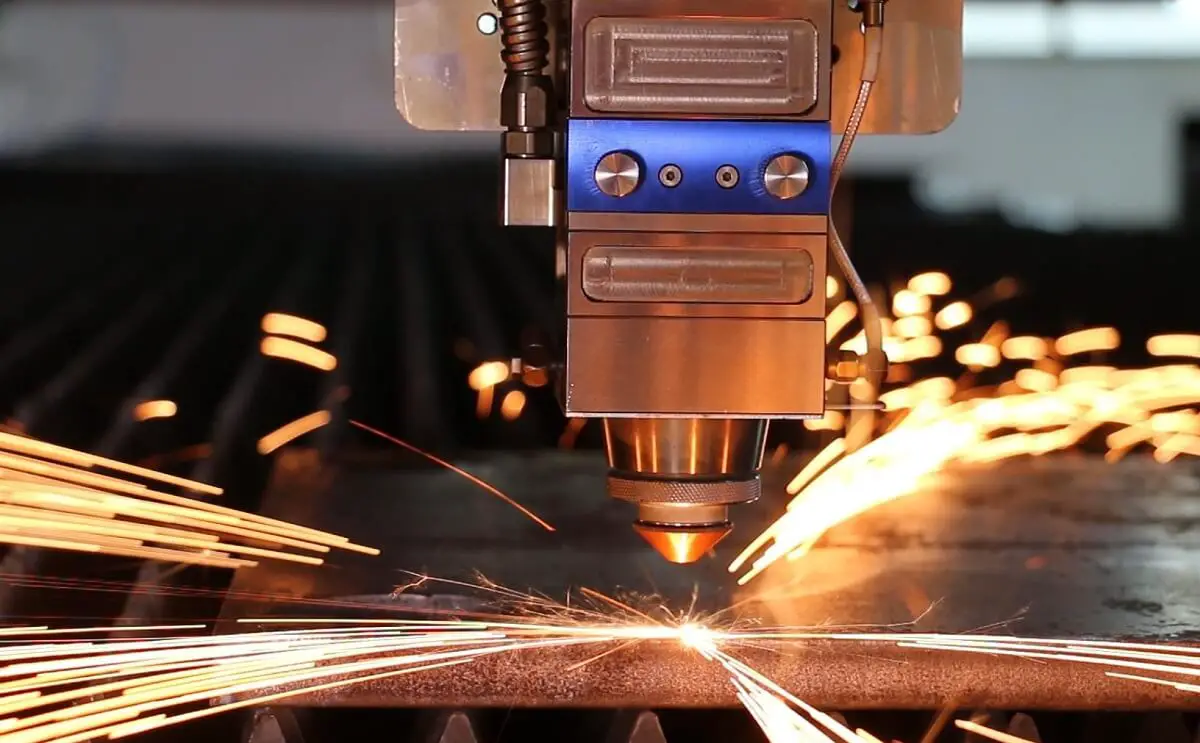

The cutting principle of air is actually similar to that of nitrogen. It uses laser energy to melt the metal and high pressure to blow away the molten material. During the process, some metal substances may oxidize or burn, leaving metal oxides on the cut surface, such as gray solid alumina (Al2O3), black solid black iron oxide (Fe3O4), and copper oxide (CuO).

Air, which is naturally present in the atmosphere, can be compressed into an air storage tank, filtered, cooled, and dried to remove any water and oil, making it usable for cutting. The 21% oxygen content in air can partially make up for the lack of oxygen and nitrogen.

In theory, air can cut any metal material that can be melted by laser energy.

Air cutting efficiency and effect experiment

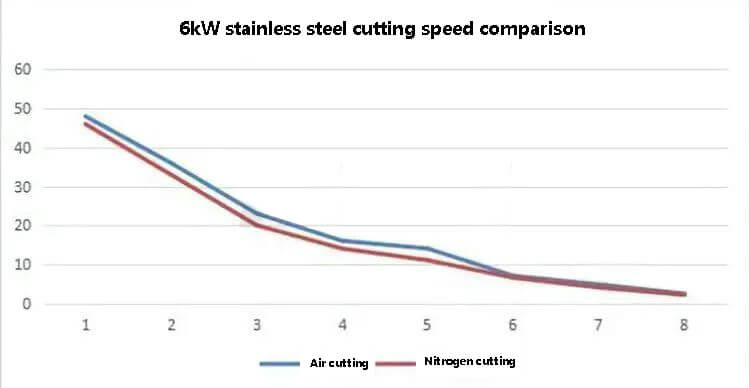

Evaluation of cutting performance on stainless steel, carbon steel, and aluminum alloy plates using a 6kW laser cutting machine with air and nitrogen/oxygen as the cutting gases.

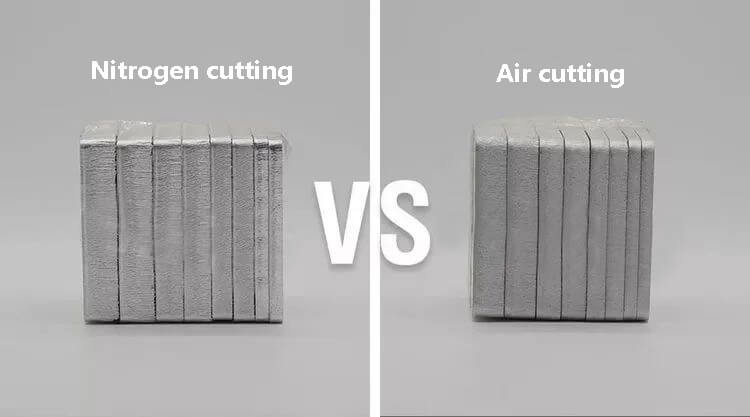

Experiment 1: comparison of nitrogen and air cutting stainless steel

⊙ Comparison of nitrogen and air cutting section effect

⊙ Comparison of nitrogen and air cutting speed

Effect analysis:

The figure above displays the cutting results of 10mm to 4mm stainless steel, in that order.

Compared to nitrogen cutting, the cut section using air appears darker, but there is no slag present. After polishing, the cut section can also achieve a brighter appearance.

In terms of speed, air cutting of stainless steel is slightly faster than nitrogen, but the difference is not significant.

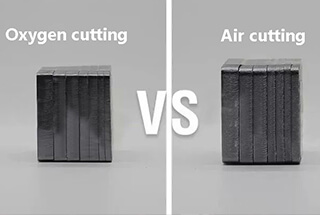

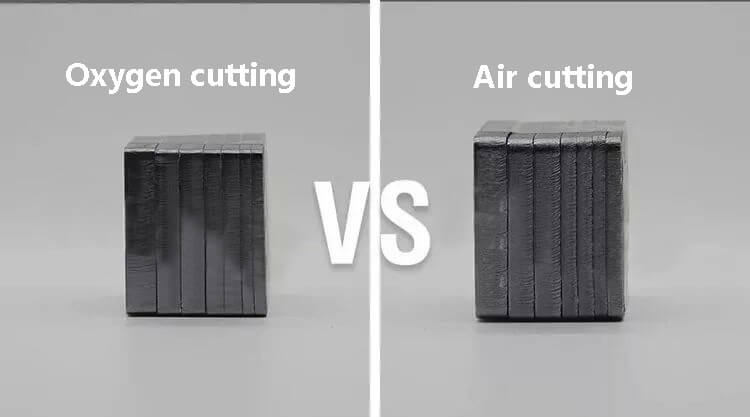

Experiment 2: comparison of oxygen and air cutting carbon steel

⊙ Comparison of oxygen and air cutting section effects

⊙ Comparison of air and oxygen cutting speed

Effect analysis:

The above figure displays the cutting results of 10mm to 3mm carbon steel, in that order.

Compared to oxygen cutting, 8mm carbon steel has slight slag residue, and the 10mm carbon steel has more severe slag residue.

Therefore, air cutting is not recommended for cutting carbon steel plates thicker than 10mm.

Experiment 3: comparison of nitrogen and air cutting aluminum alloy

⊙ Comparison of nitrogen and air cutting section effect

⊙ Comparison of nitrogen and air cutting speed

Effect analysis:

The above figure displays the cutting results of 10mm to 3mm aluminum plates, in that order.

Compared to nitrogen cutting, air cutting results in a finer section and less slag residue.

In terms of speed, air cutting of aluminum plates is slightly faster than nitrogen, but the difference is not significant.

Experiments were conducted to compare the performance and efficiency of air and nitrogen/oxygen cutting on plates of various materials and thicknesses.

Based on a comprehensive evaluation, for relatively relaxed requirements, air cutting is a cost-effective option. Using air as the cutting auxiliary gas can also significantly reduce production costs.

But it should be noted that:

When using compressed air for cutting, it is crucial to ensure that the air is treated by a cold dryer to reach a pressure dew point of 3-8°C and undergo multi-stage degreasing. The air should have a liquid oil content of 0.003 ppm and vapor oil content of 0.003 ppm, requiring the use of a filter specifically designed to remove gaseous oil.

Regular maintenance of the air compressor, cold dryer, and filter is necessary to maintain the dryness of low-oil compressed air. Contaminants such as water and oil in the air can quickly pollute the gas pipeline and cause fog on the protective lens, affecting cutting quality. Neglecting to replace the protective mirror in a timely manner can also lead to damage to the internal mirror group, as the high-power beam may cause the internal temperature of the cutting head to rise.

To find the most cost-effective cutting solution that best meets current cutting needs, the cutting efficiency, cost, and effect should all be taken into consideration in the production process, leading to a higher quality production outcome.