Ever wondered why your metal parts aren’t as smooth as you’d like? Burrs, those tiny metal fragments, might be the culprit. In this article, we’ll explore what burrs are, their types, and various deburring methods. As an experienced mechanical engineer, I’ll share insights on how to achieve precision in metalworking. Get ready to learn effective techniques to enhance your product’s quality and performance!

Regarding burr, let’s start by defining what burrs are.

Burrs are tiny metal particles that form on the machined surface of a workpiece. These fine particles are created as a result of metal casting, grinding, cutting, milling, and other similar processes.

The formation of burrs varies depending on the manufacturing process used. Based on these processes, burrs can generally be classified into:

Typically, the size of the burr, which is the excess material produced at the joint of the mold or the root of the gate, is measured in millimeters.

At the joint of the metal mold, burrs are caused by the plastic deformation of the forging material.

Electric welding and gas welding burrs:

The electric welding burr refers to the excess filler material that protrudes from the surface of the part.

Gas welding burrs are the slag that overflows from the cut during the gas cutting process.

During stamping, a gap exists between the punch on the die and the lower die, or between the cutters at the notch, which results in the generation of burrs due to die wear.

The shape of the stamping burr varies based on factors such as the material of the plate, the thickness of the plate, the gap between the upper and lower dies, and the shape of the stamped parts.

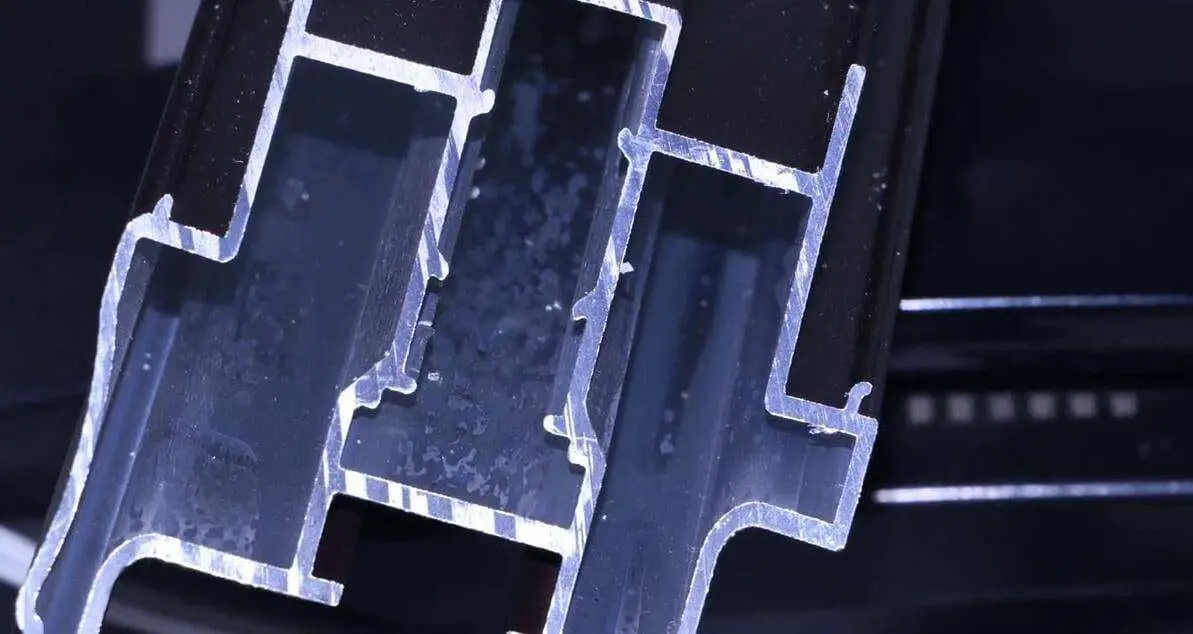

Turning, milling, planing, grinding, drilling, reaming, and other processing methods can also create burrs.

The burrs produced by these various machining methods have different shapes, which are influenced by the type of tool used and the parameters of the process.

Like casting burr, burr generated at the joint of plastic mold.

The generation of burrs occurs due to the gap at the joint between the mold and the die.

Currently, it is challenging to eliminate burrs completely due to the imperfect alignment between the mold and the die.

However, with advancements in metal materials that are becoming harder, stronger, and more durable, there are an increasing number of complex integral components in mechanical products, making deburring increasingly difficult.

As technology advances and product performance improves, the demand for higher quality products grows, making the removal of burrs from workpieces increasingly important.

The presence of burrs not only detracts from the appearance of products, but also significantly lowers the quality standard of metal workpieces and impacts their assembly, performance, and lifespan.

To mitigate the occurrence of burrs, it is crucial to choose high-quality cutting tools that minimize their appearance, such as milling cutters with a smooth finish.

Even with the proper tools, removing burrs may still require a secondary deburring operation.

This secondary deburring process can account for up to 30% of the cost of finished parts and is challenging to automate, making burrs a persistent problem.

Manual deburring techniques are insufficient in meeting the demands of modern deburring requirements, leading to the development of new, automated deburring technologies and processes.

Next, I will discuss the following deburring methods:

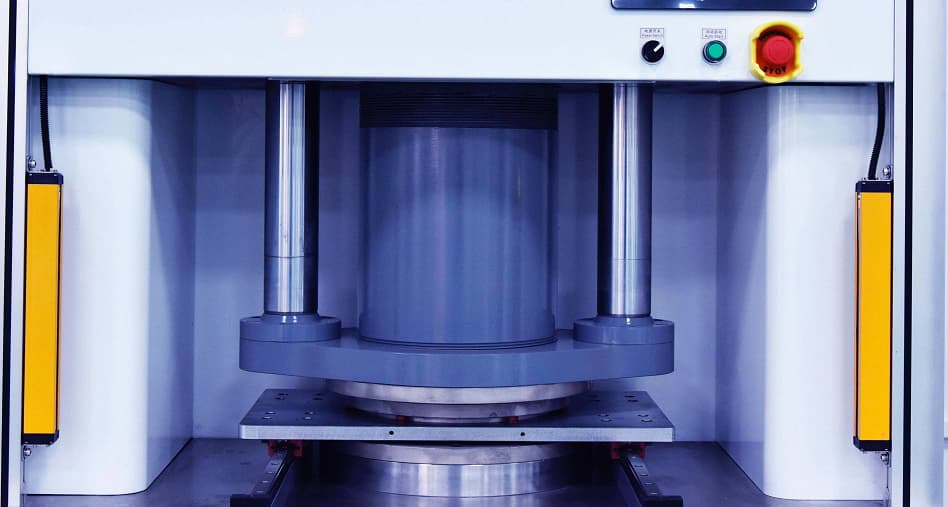

The deburring process is accomplished by using a die in conjunction with a punch press.

Blanking die deburring incurs both rough die and fine blanking die production costs and may require the creation of a shaping die. Additionally, the tooling may need to be replaced frequently.

This method is appropriate for products with a straightforward parting surface and is more efficient and effective than manual deburring.

Grinding deburring is a widely used method for deburring, which involves techniques such as vibration, sandblasting, and roller.

However, the issue with grinding deburring is that it may not always result in a completely smooth surface, which may necessitate further manual intervention or the use of additional deburring methods.

This method is ideal for small products that are produced in large quantities.

High temperature deburring, also referred to as thermal deburring and thermal explosion deburring, is a process that involves introducing natural gas into an equipment furnace and causing it to explode instantaneously through specific media and conditions. This explosion generates energy that is used to dissolve and remove burrs.

This method requires expensive equipment, typically costing over one million yuan, and operates with high technological requirements.

However, the deburring efficiency of this method is low and can result in side effects such as rust and deformation.

Thermal explosion deburring is mainly used on high-precision parts in industries such as automotive and aerospace.

Frozen deburring is a process that involves a rapid drop in temperature to quickly make the burr brittle, followed by spraying projectiles to remove the burr.

This method is ideal for products with thin burr walls and small workpieces.

However, the cost of the complete set of equipment is not inexpensive, typically ranging from two to three hundred thousand yuan.

Chemical deburring is an automated process that selectively removes burrs from metal parts using the principle of electrochemical reaction. It is particularly useful for removing internal burrs that are challenging to remove, such as fine burrs on pump bodies, valve bodies, and other similar products.

The cost of this set of equipment for removing burrs on workpieces using an engraving machine is typically only in the tens of thousands of yuan, making it an affordable option for removing burrs with simple spatial structures and regular positions.

A technique for eliminating burrs from metal components using electrolysis:

The cathode tool, typically made of brass, is positioned close to the burred section of the metal piece with a specific distance between them.

When machining, the cathode tool is connected to the negative terminal of a DC power source, while the metal piece is connected to the positive terminal.

Low-pressure electrolyte is then allowed to flow between the metal piece and the cathode.

Once the DC power source is activated, the burr will be dissolved by the anode and removed, carried away by the electrolyte.

Advantages:

It is utilized to eliminate the burr from concealed parts, cross holes, or intricately shaped components with high efficacy.

Typically, the process only takes a few seconds to a few tens of seconds.

It is ideal for deburring gears, connecting rods, valve bodies, crankshaft oil passage orifices, as well as rounding sharp corners.

Disadvantages:

The area around the burr of the component is also impacted by electrolysis, causing the original shine of the surface to be lost and potentially affecting its dimensional accuracy.

Additionally, electrolyte has a corrosive effect, so it is necessary to clean and prevent rust after deburring.

The transmission of ultrasonic waves can also produce momentary high pressure, which can be utilized to eliminate burrs on components. This method boasts high precision and is primarily employed to eliminate small burrs that can only be seen under a microscope.

The instantaneous impact of water is utilized to eliminate burrs and flash that are produced during machining, while also fulfilling the objective of cleaning.

It is categorized into two categories: workpiece-moving type and nozzle-moving type.

Workpiece moving type

This tool is cost-effective and suitable for deburring and cleaning simple valve bodies. However, it has a drawback in that the compatibility between the nozzle and valve body is not optimal, and it may not provide effective deburring for cross holes and oblique holes in the valve body.

Nozzle movable

The distance between the nozzle and the burr-generating part of the valve body can be effectively adjusted through CNC control, which corresponds to the burrs in the cross holes, oblique holes, and blind holes inside the valve body. However, this equipment is cost-prohibitive.

Advantages:

Good removal effect and fast speed.

Disadvantages:

Basic equipment is not sufficient, and premium equipment is not affordable.

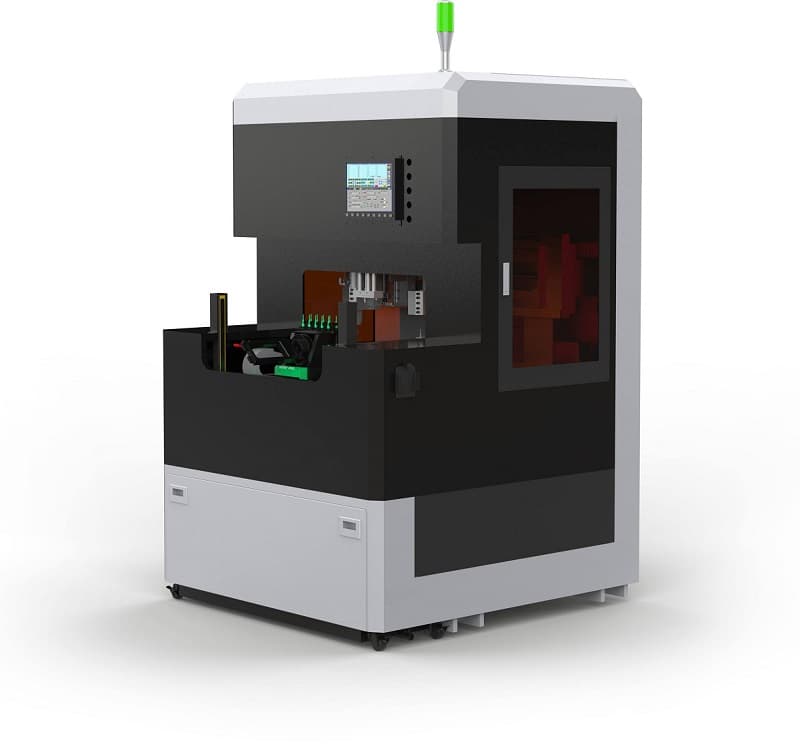

Mechatronic devices incorporate the latest advancements from various disciplines such as machinery and precision machinery, microelectronics, computers, automatic control and drive systems, sensors, information processing, and artificial intelligence.

Some common components of mechatronic devices include an aluminum hub, a frequency converter housing, a synchronizer housing, a synchronizer gear hub, a bearing cover, a cylinder block, a valve body, a valve cover, an output shaft, and an engine gear.

Advantages:

Disadvantages:

The unique magnetic field distribution produces a strong and stable magnetic induction effect, allowing for full grinding of the magnetic steel needle and the workpiece in all directions and at multiple angles for efficient deburring.

Advantages:

This method is effective for complex shapes, crevices in multi-hole parts, internal and external threads, etc.

Disadvantages:

It may negatively impact the magnetism of products with magnetic properties, so caution should be exercised when using it.

Manual deburring is currently utilized by many small manufacturers.

Most burrs are small, and the removal rate is not particularly high, as long as there are no burrs present.

The tools used for manual deburring used to include files, scrapers, and sandpapers, but now edge trimmers are predominantly used.

Advantages:

Disadvantages:

This type of deburring is not significantly different from manual deburring, except that different tools are used.

Manual deburring involves using cold tools. Some examples of these tools include a grinding machine and an electric drill, which can deburr and chamfer using milling cutters, drill bits, grinding heads, and other materials.

Different tools can be used to complete the deburring of most workpieces.

Advantages: It offers high flexibility and can adapt to the grinding of most workpiece environments.

Disadvantages: The speed is slow, and it is prone to causing some damage to the workpiece.

Here are six steps to prevent burrs in the design process:

(1) Adopt appropriate processing methods:

In metal cutting, the size and shape of the burrs produced by various processing methods vary. In the design process, it’s best to choose a method that generates the smallest burrs possible. For example, when machining flat surfaces, up-milling is more effective than down-milling.

(2) Reasonably arrange the processing sequence:

When arranging the processing sequence for parts, try to place the process that generates the largest burrs first and the process that generates the smallest burrs last, using the next process to remove the burrs generated in the previous process. For example, when machining shaft parts with keyways, it’s more reasonable to change the typical machining sequence of turning before milling to milling before turning.

(3) Wisely choose the direction:

Based on the corner effect of burrs, during metal cutting, the outlet should be located at the part with a large corner angle to reduce burr formation. At the same time, it’s important to note that the cutting edge should be located in a place where removing burrs is easy, to reduce the cost of removing them.

(4) Appropriately select cutting parameters:

In the cutting process for parts, using a method that produces large chips will result in large burrs. This is because producing large chips increases cutting resistance, cutting heat, tool wear, and decreases durability, as well as increases plastic deformation of the workpiece material, all of which result in larger burrs. Therefore, when processing parts, it’s generally best to reduce burr formation by reducing cutting depth and amount, especially in precision processing.

(5) Reasonably arrange the heat treatment process:

The heat treatment process should be arranged at different stages of the processing process to change the physical and mechanical properties, such as hardness and elongation, of the workpiece material, which can reduce the burrs generated during processing. For example, in batch production of parts, using a forming grinding wheel to grind the snap ring groove of shaft parts all at once after heat treatment generates more burrs than the process of reheating treatment after turning.

(6) Use accessories in processing:

In the process of part cutting, various accessories can be used at the cutting edge of the part, such as an auxiliary support, mandrel, or low-melting-point alloy filler. These are used to improve the rigidity of the cutting edge of the machined part, reduce cutting deformation, and reduce the formation of burrs at the cutting edge. Although burrs are inevitable in the processing process, it’s best to solve the burr problem from the process to avoid excessive manual intervention.