Have you ever wondered how everyday items like electronics, cars, and medical devices are made so precisely? The answer lies in sheet metal fabrication. This blog delves into 24 key techniques, from bending and laser cutting to welding and polishing, that transform raw metal into functional components. Explore these methods to understand the intricacies of modern manufacturing and discover how quality and efficiency are achieved in the industry.

With advancements in technology and the availability of high-performance equipment, the complex process of sheet metal fabrication is becoming increasingly sophisticated.

Sheet metal processing has a wide range of applications across various industries.

It is an essential component in industries such as electronics and electrical appliances, automobiles, communications engineering, and medical devices.

Sheet metal fabrication technology encompasses a wide range of cold processing techniques for sheet metal.

As the use of sheet metal components continues to grow, sheet metal processing technology has become an integral part of product development.

Designers must have a good understanding of the properties of sheet metal in order to balance functional and aesthetic requirements, as well as to simplify the design and streamline the production process for cost-effectiveness and efficiency.

This article will provide an overview of 24 common processes in sheet metal fabrication.

Blanking

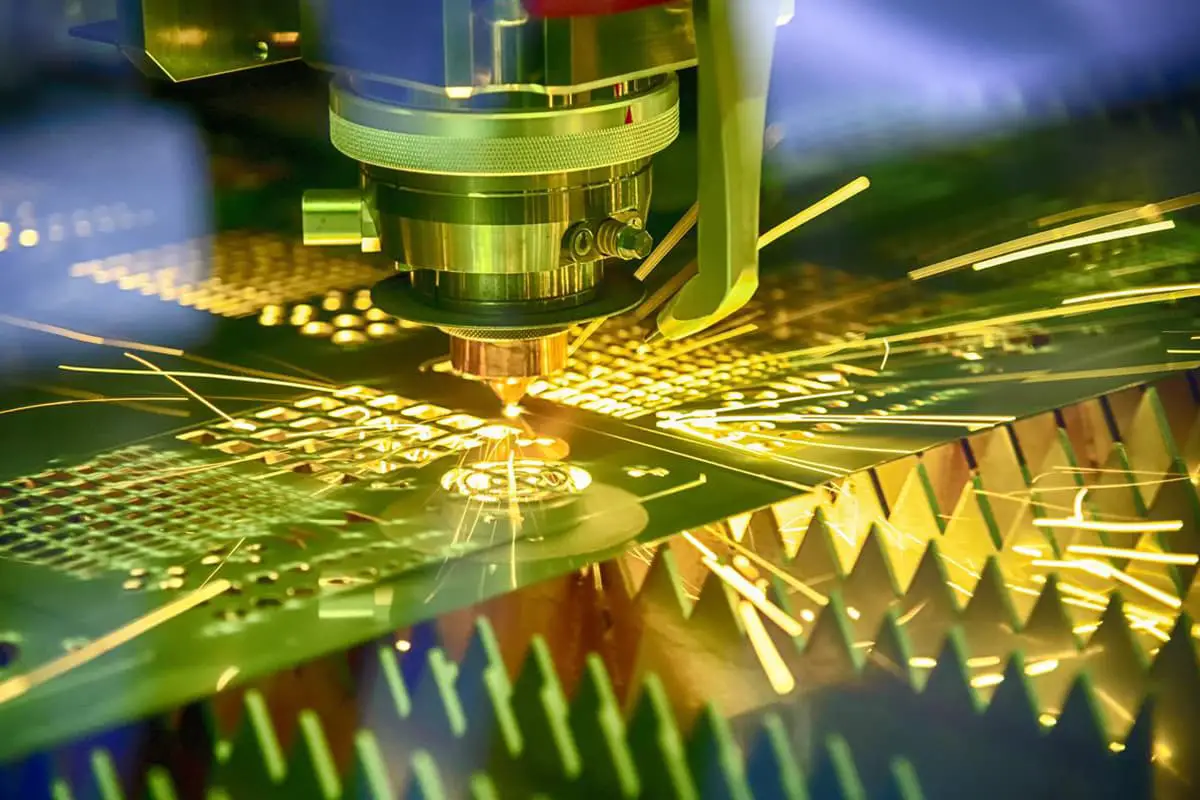

The laser cutting machine or punch machine operates based on programming files to process materials.

The laser cutting machine is capable of cutting parts of various shapes, while the punch machine excels in processing materials in bulk.

Bending

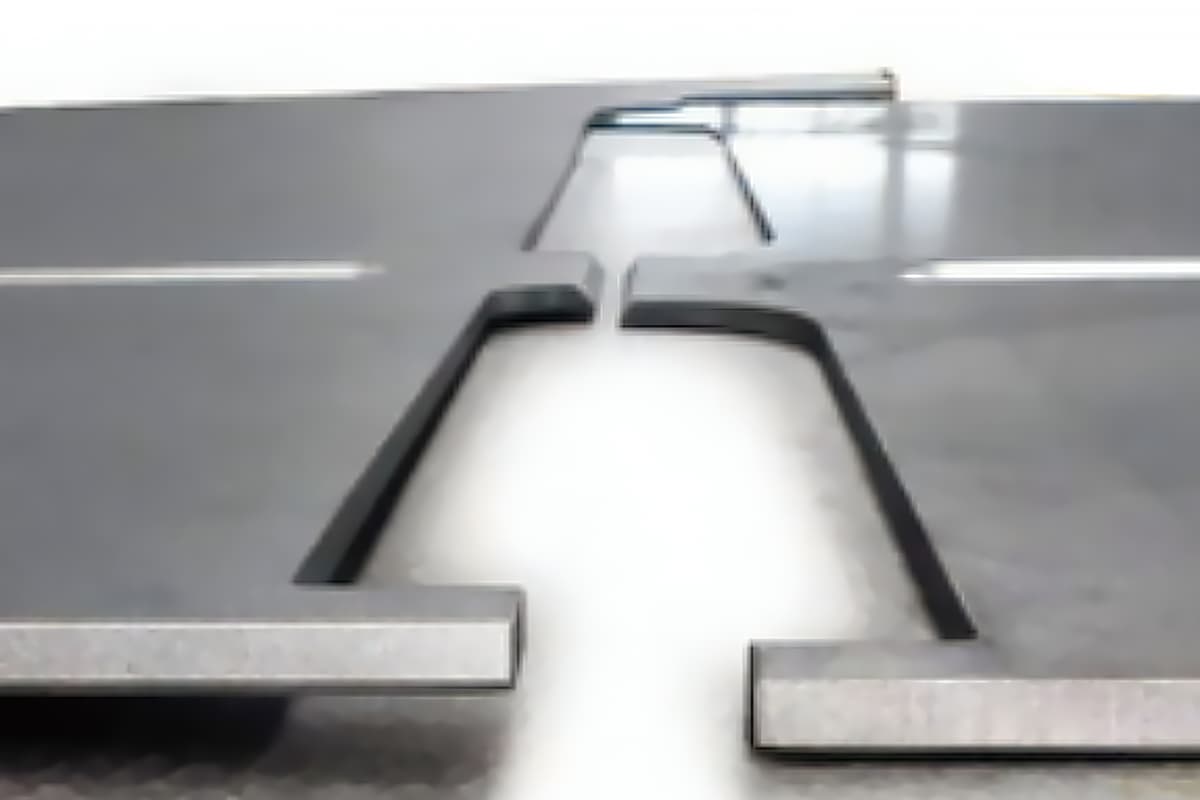

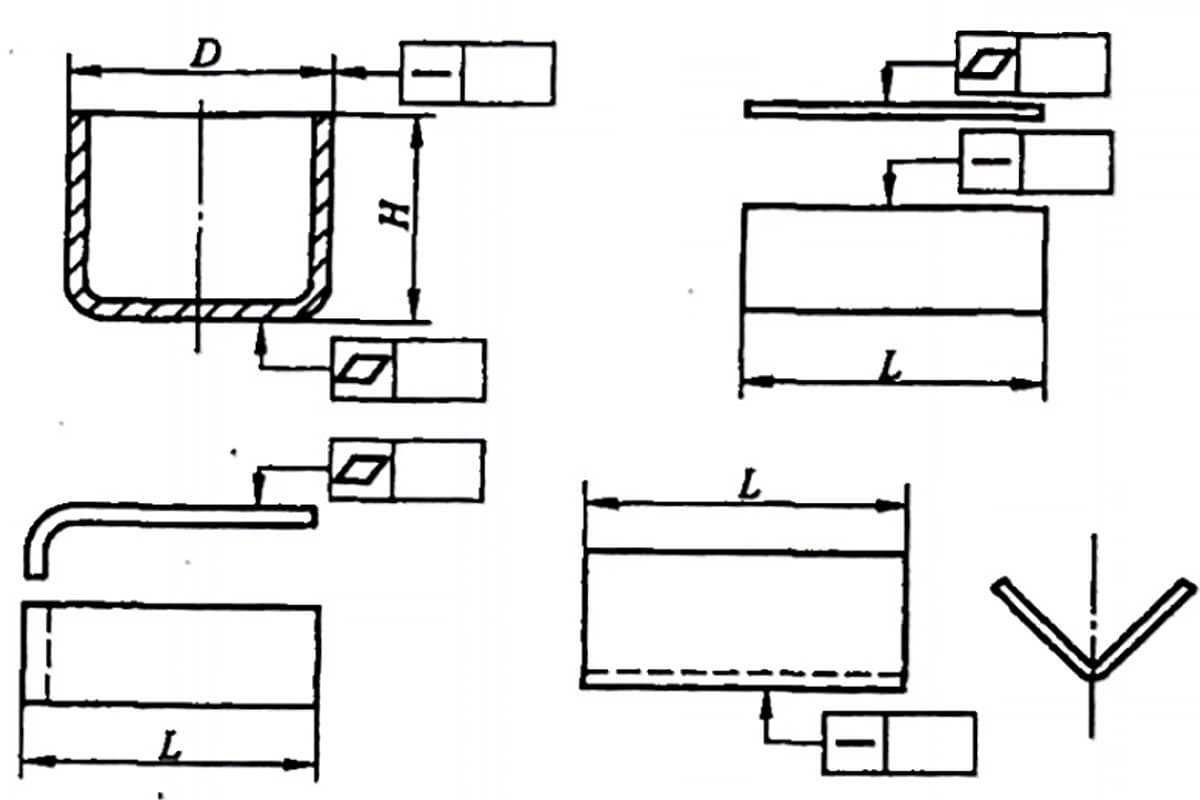

The press brake machine is used to bend and form the workpiece according to the specified dimensions on the bending drawing.

The bending die consists of an upper die and a lower die, and different shapes require different dies.

The accuracy of the bending dimensions is dependent on the quality of the die.

Forming

A die is utilized on a standard punch press or other equipment to shape the workpiece into the desired form.

Most forms are achieved through stamping forming, which is widely utilized in the automotive sheet metal and electronics industries.

Tapping

A corresponding internal thread is created on the workpiece according to the bottom hole.

Tapping has requirements for plate thickness, as too thin plates can easily slip.

Counterbore

Taper holes are machined onto the workpiece. In order to have a presentable appearance with no exposed screw head, the workpiece is often fitted with counterbores.

Press Riveting

The punch or hydraulic press is used to firmly crimp fasteners, such as press riveting nuts, screws, or nut columns, onto the workpiece.

A bottom hole must be pre-drilled in the workpiece for press riveting, and the fasteners are pressed onto the workpiece during bending, reducing the need for welding and preserving the appearance of special workpieces.

Punch Convex Hull

A punch or hydraulic press uses molds to shape the workpiece into a convex form, such as punching louvers.

Different molds are required for different shapes and, in general, the result is both aesthetically pleasing and functional.

Printing

Characters, symbols, or other shapes are stamped onto the workpiece using a die, typically including the company name, logo, website, and contact number.

One advantage of this process is that the information is permanently imprinted on the workpiece.

Punching Mesh

Mesh holes are punched into the workpiece using a die on an ordinary punch press or CNC punch.

The mesh on the workpiece serves both as a decorative element and a means of heat dissipation.

Deburring

Rough edges on the workpiece surface can be smoothed and flattened by using a grinding machine, file, or other tools to prevent cutting or scratching.

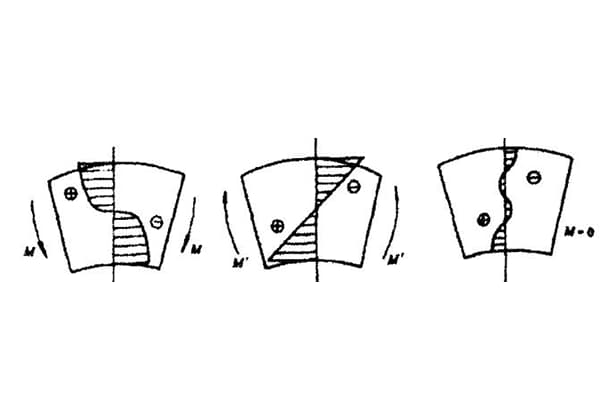

Argon Arc Welding

The connection between two workpieces is welded at the edge or joint using an argon arc welding machine, which can be performed as either intermittent welding or full welding.

The method must be clearly indicated on the drawing.

Argon arc welding is known for its stable arc combustion, high production efficiency, minimal welding deformation, and ease of operation and observation.

Planting Welding

The planting welding screw is securely welded onto the workpiece using a planting welding gun.

Planting welding is frequently used on workpieces that experience low stress and require a pristine outer surface.

Welding and Grinding

The welding scars on the workpiece are smoothed and flattened using a grinding machine, file, or other tools to achieve a better forming surface and improve adhesion for subsequent plastic powder spraying.

Pretreatment

Before painting or powder spraying, the processed workpiece must be degreased and derusted using an electrolytic solution. A coating, such as a phosphating film, is added and cleaned on the workpiece surface to increase adhesion for the plastic powder spray.

Dust Scraping and Grinding

Defects on the workpiece surface, such as welding gaps or pits, are filled with atomic ash, and the surface is polished after scraping with a flat grinder or abrasive cloth to increase parallelism, appearance, and adhesion for the plastic powder spray.

Wire Drawing

A texture treatment is applied to the workpiece surface using a wire drawing machine and abrasive belt to enhance aesthetics and market appeal, primarily for stainless steel surfaces.

Polishing

Polishing equipment is used to polish the workpiece surface, enhancing aesthetics and surface smoothness, mainly for stainless steel surfaces.

Heat Treatment

Heat treatment is performed to improve the hardness of the workpiece and enhance its mechanical properties, such as hardness, wear resistance, and strength.

Fuel Injection

Paint is evenly applied to the workpiece surface using a spray gun, providing a convenient, fast, and easy-to-use method.

Plastic Spraying

Powder is evenly sprayed onto the workpiece surface using a spray gun and baked in an oven, providing better wear and corrosion resistance.

Blackening Treatment

A chemical surface treatment is used to produce an oxide film on the metal surface, isolating it from air and preventing rust.

Silk-Screen Printing

Special ink is used to create words or patterns on the workpiece surface by penetrating through a special grid.

Silk-screen printing is known for its durability, range of applications, and fast and convenient operation.

Laser Marking

A surface treatment based on optical principles, where a laser beam is used to engrave permanent marks of various shapes onto the workpiece surface.

With the rapid progress of industrialization, the processing and manufacturing of sheet metal parts are also becoming increasingly advanced and intelligent.

As the outer layer of mechanical products, the quality of sheet metal parts plays a critical role.

To ensure that the surface forming of sheet metal parts meets the standards, it is necessary to guarantee the quality from two perspectives: surface quality and internal quality.