Have you ever wondered which companies lead the market in plasma cutting technology? This article dives into the top 10 plasma cutting machine manufacturers of 2023, highlighting their innovations and market impact. From the detailed advancements of companies like Hypertherm and Lincoln Electric to the expansive reach of Panasonic and RILAND, you’ll gain insights into what sets these industry leaders apart. Discover the latest trends and technologies shaping the field and understand how these top brands continue to push the boundaries of precision and efficiency in plasma cutting.

Country: Chian

Founded: 2003

About the company:

Shenzhen Riland Industry Co., Ltd. is a national high-tech enterprise that has been continuously focused on researching and developing, manufacturing, selling, and servicing inverter welding and cutting equipment, automation welding series products, welding accessories, and protective gear.

The company went public on the Shenzhen Stock Exchange’s Growth Enterprise Market in December 2010 and is the domestic A-share listed company in the inverter welding equipment industry (stock code: 300154). The company currently has around 1000 employees, including about 200 technical personnel.

The company owns four main brands: Riland, Rilon, Hitronic, and T&R (over 100 models under these brands). Its primary products include inverter DC manual arc welding machines, inverter argon arc welding machines, inverter semi-automatic gas shielded welding machines, inverter air plasma cutting machines, robot welding system integration, automation welding carriages, digital intelligent welding equipment, efficient welding systems, welding and cutting accessories, and welding protective gear.

The company’s products have excellent quality and relatively high cost-effectiveness and are widely used in industries such as oil pipelines, chemicals, automobiles, shipbuilding, steel structures, boilers, power generation, nuclear power, aviation, military, industrial installation, and bridge construction.

As a technology-driven company, the founder of the company, Mr. Qiu Guang, developed an inverter field effect transistor manual arc welding equipment as early as 1987. Then, he launched a series of products such as inverter argon arc welding equipment, CO2 gas shielded welding equipment, inverter air plasma cutting machines, and pioneered 100kHz frequency inverter technology, achieving product intensification and light weighting.

Since its registration in 2003, the company has always maintained its core competitive advantage of ‘technological innovation’ and has developed a strong R&D team and advanced R&D equipment.

In October 2009, the company jointly established the ‘Digital Welding Laboratory’ with the National Key Laboratory of Advanced Welding and Joining in the domestic welding field.

The company’s R&D center has successively been recognized as Guangdong Province’s small and medium-sized enterprise innovation industrialization demonstration base, Shenzhen Engineering Center, and Baoan Open Research and Development Base. The company is a drafting and formulation unit for national standards and has participated in the development and modification of 21 national welding and cutting standards.

As of December 31, 2017, the company has 180 valid national patents, including 27 invention patents, 90 utility model patents, and 63 design patents. It also holds 51 computer software copyrights.

The company’s sales and service network covers more than 60 countries or regions on five continents and has nearly a hundred overseas customers or distributors and over 2,000 domestic distributors.

Country: Japan

Founded: 1994

About the company:

Panasonic Group is a global electronics manufacturer engaged in business activities such as production and sales of various electrical products. Its business activities in China involve research and development, manufacturing, sales, service, logistics, and promotion.

Panasonic (China) Co., Ltd. was established in 1994 and became wholly-owned in 2002, mainly responsible for the sales and after-sales service activities of consumer electronics, systems, environment, components, and other goods.

As an investment company in China, Panasonic (China) Co., Ltd. is also responsible for comprehensive and supporting activities such as talent development, finance, legal affairs, environmental protection, intellectual property, and quality management. In January 2012, Panasonic (China) Co., Ltd. absorbed and merged with Panasonic Electric Works (China) Co., Ltd., further expanding its business scope.

In April 2019, Panasonic Group established for the first time the regional business company that combines both unified functional businesses and territories – China Northeast Asia Company. Based in Beijing, this is Panasonic Group’s first overseas establishment of a business company.

The China Northeast Asia Company will contribute to the ‘living space’ field, which integrates traditional strengths in consumer electronics and residential equipment and ‘fresh food supply chain’ field centered on cold chains, from the perspective of local demand in China.

Country: China

Founded: 1998

About the company:

Shanghai General Electric Welding Machine Co., Ltd. was founded in 1998 and is a national specialized and innovative ‘Little Giant’ enterprise that integrates research and development, manufacturing, sales, and service of welding machines. The company’s products are widely used in industrial manufacturing fields such as steel structures, heavy equipment, shipbuilding, pressure vessels, machinery, bridge construction, rail transportation, pipeline production and construction, and power generation.

The company has successively provided stable and reliable digital welding equipment and comprehensive welding technical support services for key projects and well-known enterprises such as China-Pakistan Economic Corridor and China-Laos International Railway Channel under the ‘Belt and Road’ Initiative, China National Nuclear Corporation, Sichuan-Tibet Railway, Commercial Aircraft Corporation of China (COMAC) C919, Antarctica’s Taishan Station, China Merchants Group, Zhenhua Heavy Industries Group, Waigaoqiao Shipbuilding, Shanghai Disney Resort, and Hangzhou Olympic Sports Center.

The company is enterprising, bold in breaking through, and innovative. It has passed the $O management system certification and is now recognized as the ‘National Welding Machine Standardization Technical Committee Unit’, ‘National Welding Machine Industry Standard Development and Revision Order Unit’, ‘National Specialized and Innovative Little Giant Enterprise’, ‘National Electrical Industry Standardization Demonstration Unit’, ‘Shanghai Science and Technology Little Giant Enterprise’, ‘Shanghai High-tech Enterprise’, ‘Shanghai Specialized and Innovative Little Giant Enterprise’, and ‘Shanghai Enterprise Technical Center’.

The company has always adhered to its core values of ‘loyalty, responsibility, hard work, and innovation.’ Its vision is to become a ‘domestic first-class, internationally renowned’ welding industry manufacturer. It adheres to the mission of ‘providing users with overall welding solutions,’ conveys the spirit of General Electric, promotes technological innovation, and is committed to industrial development for the country. With professional R&D processes accumulation and precipitation, inheritance and innovation of excellent quality, the company persists in guarding its original intention with craftsmanship, pursuing details, insisting on quality, and using a rigorous attitude to delve into every inch of product texture to achieve excellence for its users.

Country: America

Founded: 1895

About the company:

Lincoln Electric is a global leader in the welding and cutting field, focusing on designing, researching and developing, manufacturing advanced arc welding solutions, automation welding, assembly and cutting systems, as well as plasma and flame cutting equipment. At the same time, Lincoln Electric® is also globally renowned in the brazing alloy industry.

As a recognized ‘welding expert’ in the industry, Lincoln Electric® helps customers improve their manufacturing capabilities and build a better world through its excellent material science, software development, automation engineering, and application expertise. The headquarters of Lincoln Electric® is located in Cleveland, Ohio, USA, with 56 production bases in 19 countries, and its distribution network and sales offices cover more than 160 countries worldwide.

Shanghai Lincoln Electric® Co., Ltd. is the production base for Lincoln China’s cored wires and welding equipment. Since 2006, the product series of cored wires have been continuously expanding to meet the different needs of carbon steel, low-alloy steel, stainless steel, and other materials. At the same time, the self-shielded wire series is also continuously expanding. In 2006, Shanghai Lincoln Electric® established an automation robotics department to provide customers with comprehensive robotic welding solutions.

Country: America

Founded: 1968

About the company:

In 1968, Hypertherm started in a small two-car garage with a simple yet powerful business idea and a technological invention that would change the future of industrial cutting. Hypertherm’s founder Dick Couch and his colleague Bob Dean discovered a method that could form a narrower plasma arc, which could cut metal with good speed and precision. Today, 50 years later, the entrepreneurial concept of customer supremacy and endless innovation continues to drive Hypertherm’s new product development.

This innovative spirit is one of the reasons why Hypertherm’s plasma, laser, and waterjet cutting systems, software, motion controllers, and consumables have always been ahead of their competitors in terms of cutting quality, production efficiency, and cost-effectiveness.

Hypertherm is headquartered in Hanover, New Hampshire, USA. With its innovative products, corporate culture, and excellent customer experience, Hypertherm is full of enthusiasm to embrace even greater breakthroughs. Hypertherm firmly believes that its employees, partners, and innovative ideas can open up unlimited possibilities for industrial cutting.

In order to better serve Chinese customers, Hypertherm, Inc. established a wholly-owned subsidiary called Hypertherm Trading (Shanghai) Company Limited in Shanghai, China in 2005. ‘Hypertherm’ is a proprietary trademark of the company. Hypertherm has always adhered to innovation, diligence, and customer supremacy, and is committed to designing advanced cutting solutions, thus developing into a world-class manufacturer in the field.

Country: China

Founded: 2005

About the company:

Shenzhen Jasic Technology Co., Ltd. (stock code: 300193) is a high-tech enterprise that mainly engages in the research, development, production, and sales of inverter welding and cutting equipment. After years of development, Jasic has become a leading enterprise in China’s welding equipment industry. Its products are widely used in various fields such as shipbuilding, petrochemical construction, pipeline construction, bridge construction, building construction, high-speed rail manufacturing, and vehicle manufacturing.

The company is headquartered in Shenzhen and has three R&D centers located in Italy, the United States, and Shenzhen. Its business covers more than 80 countries and regions worldwide. With 260 patents, over 200 R&D personnel, and laboratories, Jasic provides a continuous source of power for the rapid development of the enterprise.

Inverter welding and cutting power source is the main component of inverter welding and cutting equipment. The inverter welding and cutting power source mainly applies power electronics technology to practical production, while the digital control system serves as the central control unit of the inverter welding and cutting power source. Good welding process performance is the ultimate design goal of inverter welding and cutting power sources, and excellent industrial design, mechanical structure design, and information processing technology are also closely related to us.

Country: China

Founded: 1993

About the company:

Shandong Aotai Electric Co., Ltd. is a national high-tech enterprise and a global industrial welding and cutting equipment manufacturer that provides users with industrial welding and cutting equipment, robot welding systems, automated welding and cutting equipment, intelligent welding cloud systems, and their application solutions, serving different industries such as high-speed rail, shipbuilding, machinery, steel structure, metallurgy, and petrochemicals.

Since 1993, Aotai has been focusing on research and innovation in inverter technology and welding technology, and has a strong research and development team including a national-local joint laboratory, an automation welding special machine and robot laboratory, and an Internet of Things and cloud computing welding laboratory.

The ‘Aotai’ brand series of products are highly recognized by customers for their advanced technology, stable quality, and excellent craftsmanship. Since 2005, Aotai’s inverter welding machines have always been a benchmark in the domestic industrial inverter welding machine market in terms of brand influence, market share, and sales volume, far exceeding the industry’s average development speed and the development speed of major competitors.

In recent years, with the rise of smart manufacturing, Aotai’s welding robot system and automatic welding equipment have reached an advanced level in the research and manufacture of large and medium-sized production lines in China, and widely used in fields such as special vehicles, construction engineering, steel structures, coal mining machinery, and engineering machinery.

In the international market, Aotai’s products, as representatives of Chinese industrial products, have been exported to more than 60 countries and regions worldwide, including Germany, the United Kingdom, the Netherlands, Spain, Australia, South Africa, India, Russia, Southeast Asia, South America, and the Middle East.

Country: China

Founded: 1958

About the company:

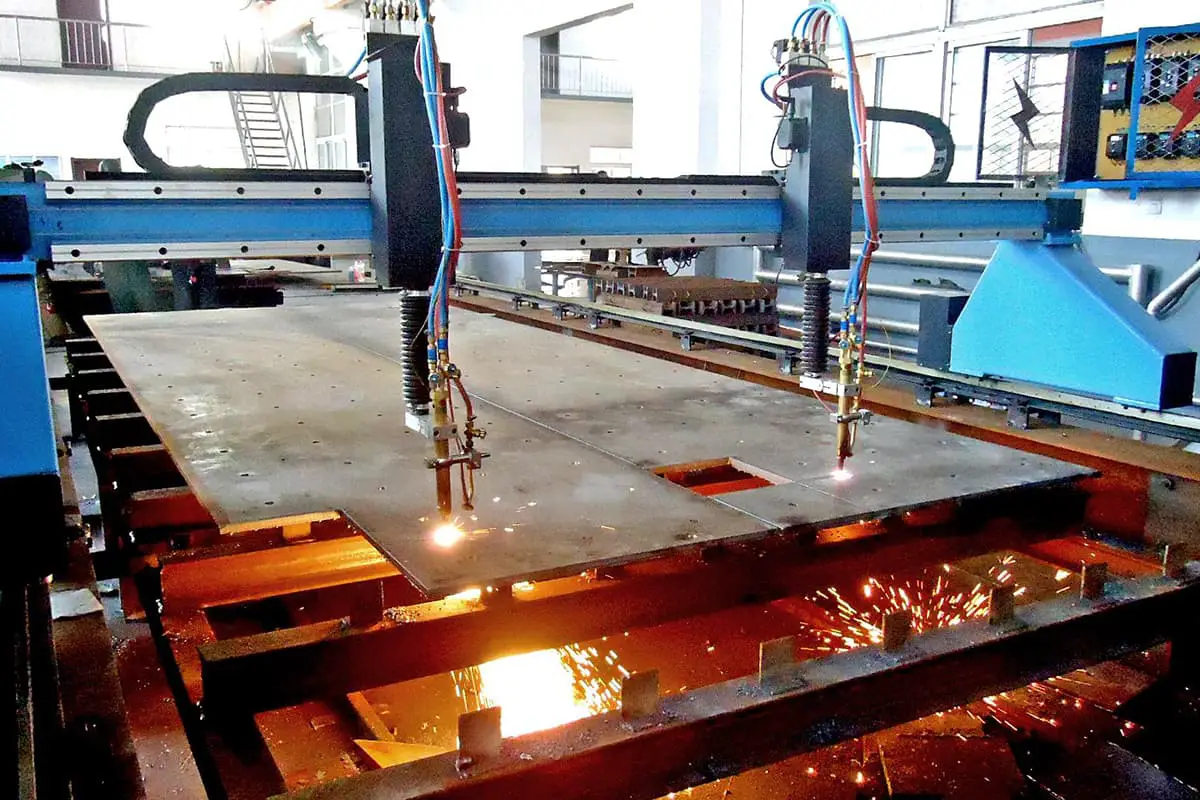

Shanghai Hugong Welding Group is an industrial equipment enterprise group that integrates research and development, production, and investment. The group has over 60 years of professional experience in welding and cutting equipment research and manufacturing. It is a listed company on the Shanghai Stock Exchange main board and a well-known enterprise in the welding equipment industry. The company mainly produces digital welding machines, high-power laser cutting machines, CNC plasma cutting machines, and robot systems.

Since its establishment in 1958, the company has accumulated core technologies in welding power sources, welding processes, and cutting equipment through more than 60 years of development, and has international competitiveness. Its products are sold to more than 110 countries and regions worldwide.

Country: China

Founded: 2001

About the company:

Beijing TIME High Technology Ltd. was established in early 2001. It is a new joint stock company initiated by TIME Group, together with Tsinghua Unigroup, Lenovo Group, Daheng Group, SITONG Group, and other companies. The company mainly engages in the development, production, and sales of inverter welding machines, large-scale welding equipment, specialized welding machines, CNC cutting machines, and arc welding robot systems.

On March 31, 2006, Beijing TIME High Technology Ltd. was listed on the Shenzhen Stock Exchange. On October 26, 2006, “Beijing TIME” became the first to raise funds on the third board market, successfully raising a targeted amount, providing better opportunities and conditions for the company’s rapid development.

TIME has a post-doctoral mobile station and more than 40 sales and service subsidiary companies across China, covering a nationwide sales and after-sales service network.

Since 1993, TIME has been engaged in the development, production, and sales of GBT inverter welding machines. All of the welding machines produced by the company now are IGBT inverter welding machines. The welding machine products have formed more than ten series and over 70 product models.

In 2003, TIME adopted digital DSP technology in the domestic welding machine industry, occupying the high ground in domestic welding machine technology. In October 2007, the company established Jinan TIME New Era Technology Co., Ltd., which is currently a wholly-owned subsidiary of TIME, mainly engaged in the development, production, and sales of large-scale welding equipment, specialized welding machines, arc welding robot systems, and CNC cutting machines. In 2013, TIME’s third-generation TD series digital welding machine was launched in the market, taking the lead in domestic digital welding machine technology.

Country: China

Founded: 2007

About the company:

Zhejiang Kende Mechanical & Electrical Co., Ltd. (Kende) is one of the creators of urban dreams. Kende upholds the craftsmanship spirit and focuses on lean production. With the goal of becoming a bigger and stronger global welding equipment manufacturer, Kende is passionately promoting the “Made in China 2025” strategy.

At first, Kende was just a small workshop with a few simple and rudimentary equipment and a handful of talents. Now, Kende has three large-scale production bases, namely the Luqiao, Pengjie, and Linhai plants, with a total area of nearly 200,000 square meters, and the Pengjie factory covers an area of 80,000 square meters.

Kende has advanced modern office environment, advanced production equipment, and a group of high-quality innovative technology R&D teams. Kende has become a world-renowned enterprise and a model in the industry.

Kende’s initial goals and philosophy were to do every small thing well and become a leader in the industry with expectations. After decades of exploration, Kende has always adhered to the craftsmanship spirit.

Over the years, Kende has focused on small products but gained a large market share, becoming a strong player. Kende insists on the market philosophy of making equipment and instruments enter thousands of households and persists in seeking development through independent innovation and practical actions.

Currently, Kende has established national-level and provincial-level enterprise technology research and development centers, carried out and successfully completed two national torch plan projects, and won multiple science and technology project and new product awards. Kende has nearly 200 national patents, utility model patents, and industrial design patents. At present, Kende has become a patent demonstration enterprise and an enterprise in the welding machine industry.

The KENDE trademark has become a well-known brand in the country, provinces, cities, and industries. Kende is also a major participant in drafting welding machine industry standards and has participated in the formulation of 20 national and industry standards. Kende was the first to obtain S09001 international quality management system certification, OHSAS18001 occupational health and safety management system certification, and 1S014001 environmental management system certification.

Kende produces and exports nearly 1.2 million electric welding machines, chargers, and heaters every year, with an annual production capacity of up to 2 million sets. Kende is one of the enterprises that produce and export more electric welding machines, chargers, and heaters in the world.

Product quality stability and reliability contribute to sustainable development. High-quality products cannot be achieved without continuous efforts. Our collective efforts demonstrate our beliefs. Kende firmly believes that quality is the life of an enterprise. By learning and adopting various quality management methods, Kende integrates quality management concepts into its corporate culture and implements quality management systems in actual production.

Kende strictly controls quality in every aspect from raw material procurement to product delivery, conducts strict quality supervision, and controls the quality of purchased raw materials. In the production process, Kende implements a first-piece quality inspection system to ensure product quality stability. Kende attaches great importance to production details, conducts spot checks on products before leaving the factory, and implements a veto system to effectively prevent unqualified products from entering the market.

Kende continuously focuses on intelligent research and development and masters cutting-edge technology. Nowadays, Kende’s products are sold all over the world and adopt international advanced technology.

Currently, Kende has many products, including various welding machines such as manual arc welding machines, argon arc welding machines, gas shielded welding machines, submerged arc automatic welding machines, resistance spot welding machines, laser welding machines, laser cleaning machines, robot welding systems, and air plasma arc cutting machines. Various types of battery chargers, including 6V, 12V, and 24V chargers. Various types of heaters, including electric heaters, natural gas heaters, and fuel heaters.

Kende draws on and absorbs international advanced management concepts to ensure that the concept of quality as the life of an enterprise is integrated into sales, production, quality control, and R&D processes.

In 2003, Kende adopted the advanced Toyota Production System. In 2005, Kende introduced enterprise resource planning management systems and other management systems. In 2008, Kende introduced excellent performance evaluation models. Kende and its employees have made great progress. Kende’s overall performance and capabilities have been greatly improved. A series of measures have greatly enhanced Kende’s ability to adapt to external changes and laid a solid foundation for strengthening its quality goals.

When selecting a plasma cutting machine manufacturer, I consider the quality and performance of their products. This includes evaluating the machine’s cutting speed, precision, and durability. I typically research online reviews and testimonials from other customers to gauge the manufacturer’s reputation in the industry.

Another significant factor for me is the price and value for money. I compare the cost of different manufacturers’ plasma cutting machines to ensure that I am getting a reliable product with a reasonable price tag. To this end, I look for deals and discounts, as well as consider the long-term operating costs of the machine.

As a consumer, I appreciate it when manufacturers offer a wide range of accessories and consumables for their plasma cutting machines. This ensures that I can easily find replacement parts or upgrade my machine as needed. Furthermore, available accessories can expand the machine’s capabilities, making it a more versatile investment.

Before making a purchase, I want to be confident that the manufacturer I choose will provide excellent customer support and service. This includes how responsive they are to my inquiries, their level of technical expertise, and whether they offer any training resources. Good customer support can save me time and frustration in the long run.

Finally, I value manufacturers that offer robust warranties and after-sales services. A comprehensive warranty gives me peace of mind, knowing that my investment is protected against manufacturing defects or issues. Similarly, reliable after-sales services, such as maintenance or repair, can contribute to the longevity of my plasma cutting machine.

In recent years, I’ve noticed significant advances in plasma cutting technology that have made the process faster, more accurate, and of higher quality. One of the key improvements is the development of high definition plasma cutters. These machines offer better cut quality and edge definition, leading to reduced secondary operations and improved overall productivity.

Another notable advancement is the incorporation of CNC (computer numerical control) technology. With CNC, I can easily automate my plasma cutting operations for better precision and repeatability. By utilizing CNC, cutting patterns can be programmed, stored, and recalled, which saves both time and effort.

Furthermore, I have observed considerable improvements in consumable technology. The electrodes, nozzles, and other components used in plasma cutting have longer lifetimes and can withstand higher cutting amperages. This not only reduces the cost of replacement consumables but also contributes to a more stable and consistent cutting process.

Rapid cutting speed is another significant advancement in plasma cutting technology. Modern systems can cut through metal several times faster than their predecessors. This allows me to complete my jobs more quickly and move on to the next project.

Additionally, I appreciate the advancements in portability and ease of use. Many portable plasma cutting machines are now available, making it easier to transport and set up in various locations. This has been particularly beneficial for those involved in fieldwork and on-site cutting.

To sum up, the advances in plasma cutting technology have greatly improved the speed, precision, and overall quality of the process, ensuring better results for operators like me.

As a professional in the field, I have found that the top 10 plasma cutting machine manufacturers offer a variety of reliable and efficient products. These manufacturers have consistently demonstrated innovation and dedication to meeting the needs of their customers.

Among these manufacturers, some stand out for their exceptional performance, durability, and versatility. For example, Hypertherm, Lincoln Electric, and ESAB provide an impressive range of options for various applications and budgets. Other noteworthy players include Miller Electric, Eastwood, and Razorweld. They offer cost-effective solutions without compromising on quality and performance.

When selecting a plasma cutting machine, it is essential to consider factors such as cutting needs, desired performance level, and budget. By taking the time to evaluate the offerings from each of these top manufacturers, I believe that customers will be able to find a suitable plasma cutting machine to meet their needs.

In conclusion, the top 10 plasma cutting machine manufacturers represent the best in the industry, offering a wide range of high-quality and innovative products. As a professional in this field, I am confident that these companies will continue to excel, providing customers with exceptional plasma cutting solutions for many years to come.