Welding Q345 steel, a low-alloy high-strength material, presents unique challenges due to its chemical composition and mechanical properties. This article explores the key characteristics of Q345 steel, common welding issues like hardening and cold cracking, and offers detailed guidelines for effective welding processes. Readers will learn about preheating techniques, suitable welding materials, and post-weld treatments to ensure high-quality, durable welds. By following these expert recommendations, professionals can achieve optimal results in welding Q345 steel.

1. The chemical composition of Q345 is shown in the following table (%)

| Element | Content |

| C | ≤0.2 |

| Mn | 1.0-1.6 |

| Si | ≤0.55 |

| P | ≤ 0.035 |

| S | ≤0.035 |

| Al | ≥0.015 |

| V | 0.02-0.15 |

| Nb | 0.015-0.06 |

| Ti | 0.02-0.2 |

2. The mechanical properties of Q345C are as follows (%)

| Mechanical performance indicators | Value |

| Elongation rate (%) | ≥ 22 |

| Test temperature 0 ℃ | ≥ 34 |

| Tensile strength MPa | 470-650 |

| Yield point MPa | 324-259 |

When the wall thickness is between 16-35mm, σs≥325Mpa; when the wall thickness is between 35-50mm, σs≥295Mpa.

2.1 Calculation of Carbon Equivalent (Ceq)

Ceq=C+Mn/6+Ni/15+Cu/15+Cr/5+Mo/5+V/5

The calculated Ceq is 0.49%, which is greater than 0.45%. This indicates that the welding performance of Q345 steel is not very good, and strict process measures need to be formulated during welding.

2.2 Common Problems with Q345 Steel During Welding

2.2.1 Hardening Tendency of the Heat-Affected Zone

During the welding cooling process of Q345 steel, the heat-affected zone is prone to form a quenched structure – martensite, which increases the hardness of the area near the seam and reduces its plasticity. As a result, cracks may occur after welding.

2.2.2 Sensitivity to Cold Cracking

The primary type of welding crack in Q345 steel is cold cracking.

Bevel preparation → Spot welding → Preheating → Inner welding → Back gouging (with carbon arc air gouging) → Outer welding → Inner welding → Self-inspection/Special inspection → Post-weld heat treatment → Non-destructive inspection (weld seam quality grade one pass)

Through the weldability analysis of Q345 steel, the following measures have been developed:

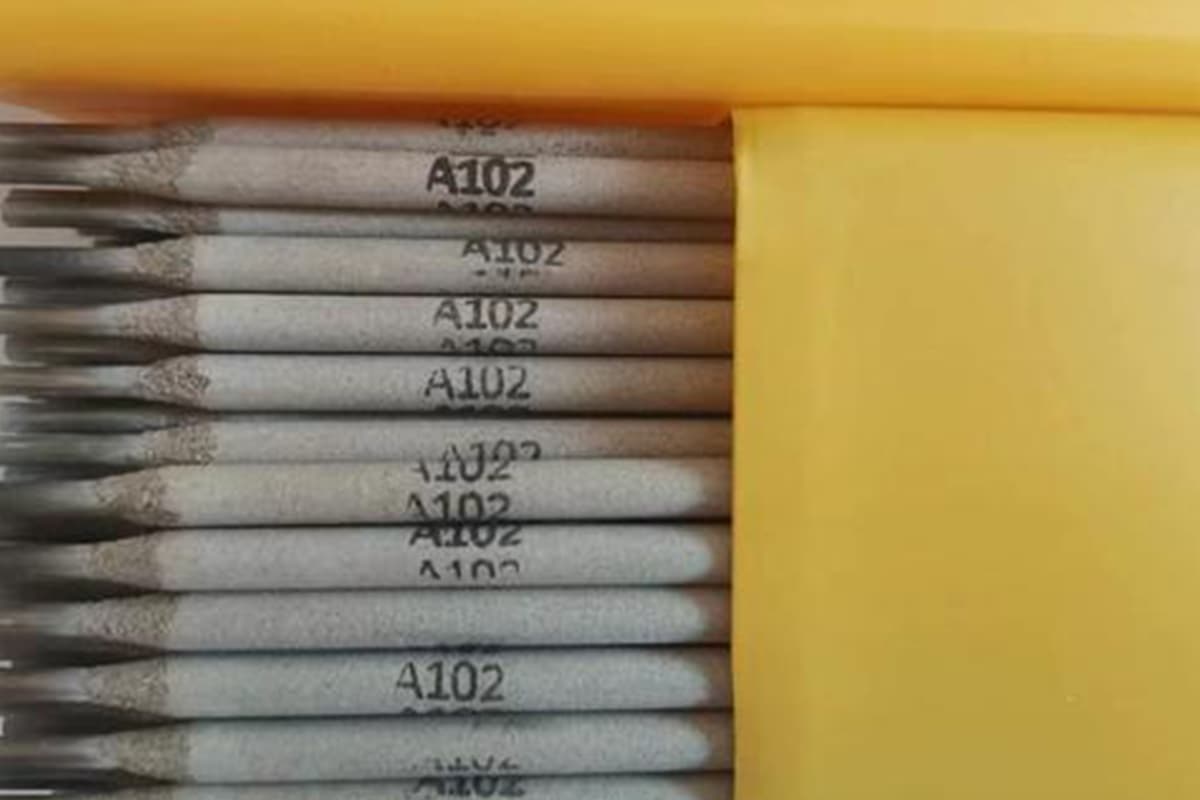

1. Selection of Welding Materials

Due to the high crack tendency of Q345 steel, low hydrogen welding materials should be used. Considering the principle that the welded joint should be as strong as the base material, E5015 (J507) type welding rod is chosen.

Chemical composition and mechanical properties are as follows (in %):

| Element | Content |

| C | 0.071 |

| Mn | 1.11 |

| Si | 0.53 |

| S | 0.009 |

| P | 0.016 |

| Cr | 0.02 |

| Mo | 0.01 |

| V | 0.01 |

| Ti | 0.01 |

The mechanical properties are shown in the following table:

| σb/Mpa | σs/Mpa | δ5(%) | Ψ(%) | Akv/J-30℃ |

| 440 | 540 | 31 | 79 | 164/114/76 |

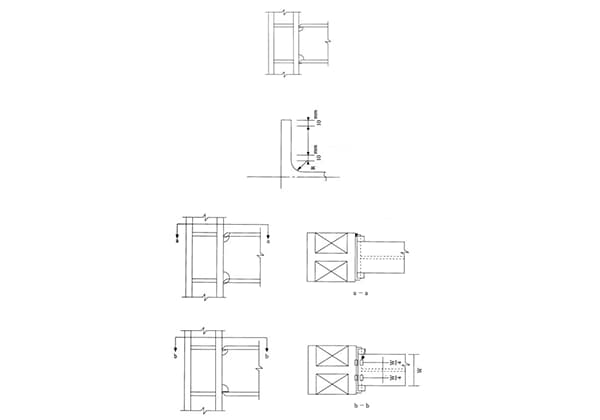

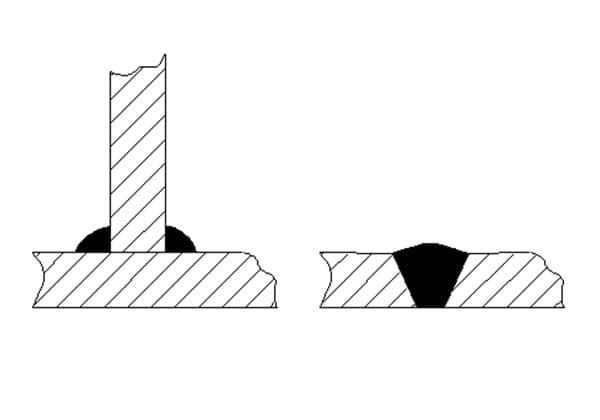

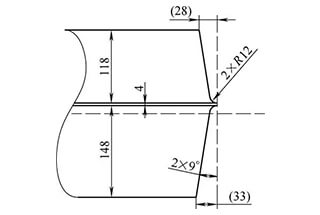

2. Bevel shape:

According to drawings and equipment supply.

3. Welding Method:

Manual Electric Arc Welding (D) will be used.

4. Welding Current:

To avoid coarse weld seam structure, which can result in a decrease in impact toughness, small specification welding must be adopted. Specific measures include small diameter welding rods, narrow welding paths, thin welding layers, and multi-layer, multi-path welding process.

The width of the welding path should not exceed three times the diameter of the welding rod, and the thickness of the welding layer should not exceed 5mm.

For the first to third layers, a Ф3.2 welding rod should be used with a welding current of 100-130A; for the fourth to sixth layers, a Ф4.0 welding rod should be used with a welding current of 120-180A.

Since the Ceq of Q345 steel is >0.45%, preheating should be done before welding, with the preheating temperature T0=100-150℃, and the interlayer temperature Ti≤400℃.

6. Post-weld Heat Treatment Parameters:

To reduce welding residual stress, decrease the hydrogen content in the weld seam, and improve the metal structure and properties of the weld seam, post-weld heat treatment should be performed on the weld seam.

The heat treatment temperature is 600-640℃, with a holding time of 2 hours (for a plate thickness of 40mm), and the heating/cooling rate is 125℃/h.

1. Pre-welding Preheating

Before welding the flange plate, preheat it first, and start welding after a constant temperature of 30 minutes.

The preheating, interlayer temperature, and heat treatment are automatically controlled by the heat treatment temperature control cabinet, using far infrared track-type heating plates, with a microcomputer automatically setting and recording the curve, and a thermocouple measuring the temperature.

During preheating, the thermocouple measurement point is 15mm-20mm from the edge of the bevel.

2. Welding

2.1 To prevent welding deformation, each column joint is welded symmetrically by two people, with the welding direction from the middle to the sides.

When welding the inner mouth (the bevel facing the belly plate), the first to third layers must use a small specification operation, as its welding is the main cause of welding deformation.

After welding the first to third layers, back gouging is performed. After carbon arc air gouging is completed, the weld seam must be mechanically polished, the carbon penetration on the surface of the weld seam cleaned, and the metallic luster exposed, to prevent severe surface carbonization causing cracks.

The outer mouth should be welded in one go, and finally the remaining part of the inner mouth should be welded.

2.2 When welding the second layer, the welding direction should be opposite to that of the first layer, and so on. Each layer of the welding joint should be staggered by 15-20mm.

2.3 The two welders should maintain consistency in welding current, welding speed, and the number of layers welded.

2.4 During welding, start from the striking plate and end on the back plate. After welding is completed, cut off and polish clean.

3. Post-weld Heat Treatment:

After the weld is completed, heat treatment should be carried out within 12 hours. If heat treatment cannot be carried out in time, insulation and slow cooling measures should be taken. During heat treatment, the temperature should be measured with two thermocouples, spot-welded on the inside and outside of the weld.

4. Weld Inspection

According to the requirements of the “Steel Structure Engineering Construction and Acceptance Specifications”, the welds are inspected using ultrasonic flaw detection, with an inspection rate of 100%.

1. Prepare detailed welding construction work instruction manuals.

2. Full process control of the welding process is the core to ensure quality.

During the welding of each column joint, a dedicated person should monitor the welding process. If the welder does not follow the work instruction manual, welding should be immediately stopped.

During the welding process, the heat treatment personnel should monitor the interlayer temperature throughout. If it exceeds the standard, the welder should be immediately notified to stop.

3. Enhancing the quality awareness of construction personnel is key to implementing the welding process.

Before construction, a full staff briefing should be held, and a construction process card should be issued. The briefing should explain in detail the characteristics of the welding process and the necessity and control points of strictly controlling the on-site welding process.

Following this welding process measure, a total of 102 welds were made on-site, with a one-time pass rate of 100% in non-destructive testing.

Through practical construction verification, this welding process measure can not only guide the welding of Q345 steel on-site but also ensure welding quality.