How can welding stainless steel tanks be more efficient and precise? The double-side argon arc welding process is revolutionizing the industry by reducing spatter, minimizing deformation, and enhancing weld quality. This technique addresses the limitations of single-side welding, ensuring stronger, cleaner joints. In this article, you’ll discover how this method improves efficiency, cuts costs, and delivers superior results for stainless steel tanks.

Stainless steel storage tanks typically feature large volumes and thin-walled plates, making them atmospheric vessels. Manual electrode welding is the most commonly used welding process.

However, this welding process can result in significant spatter, internal stress during welding, and substantial deformation on the single side of the weld, making it challenging to control the welding quality.

To address these issues, argon arc welding can be used. This process eliminates spatter and slag during welding, overcoming the shortcomings of manual electrode welding.

Stainless steel has a strong affinity for oxygen, making it susceptible to oxidation at high temperatures. As a result, single-sided argon arc welding primer often leads to the appearance of “slag weld,” resulting in “poor chromium” in the welding joint area and premature failure in corrosive environments.

Furthermore, single-side welding is heavily influenced by groove assembly and can result in welding defects such as incomplete penetration and root fusion.

To address the above defects associated with single-sided argon arc welding and the deformation caused by uneven internal stress, as well as to enhance the qualification rate of NDT film, it is recommended to use the double-sided argon arc welding process. This entails having two people weld both sides of the weld simultaneously.

|

Welding position |

Wall thickness |

Groove type |

Groove size |

||

|

interval |

truncated edge |

groove angle |

|||

|

Longitudinal weld of tank wall |

5~8 |

Single V |

1~2 |

1~2 |

65~75 |

|

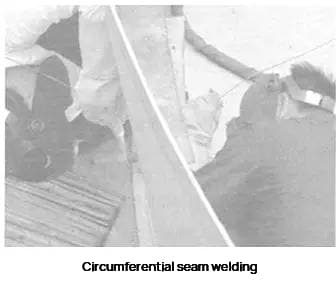

Tank wall circumferential weld |

5~8 |

Single V |

1~2 |

1~2 |

45~55 |

Note: The groove must be machined before welding. Prior to welding, all pollutants on the surface of the groove and within a 100mm radius must be removed. If necessary, the area should be dried with a dry rag. The alignment and misalignment of the inner weld should not exceed 0.5mm.

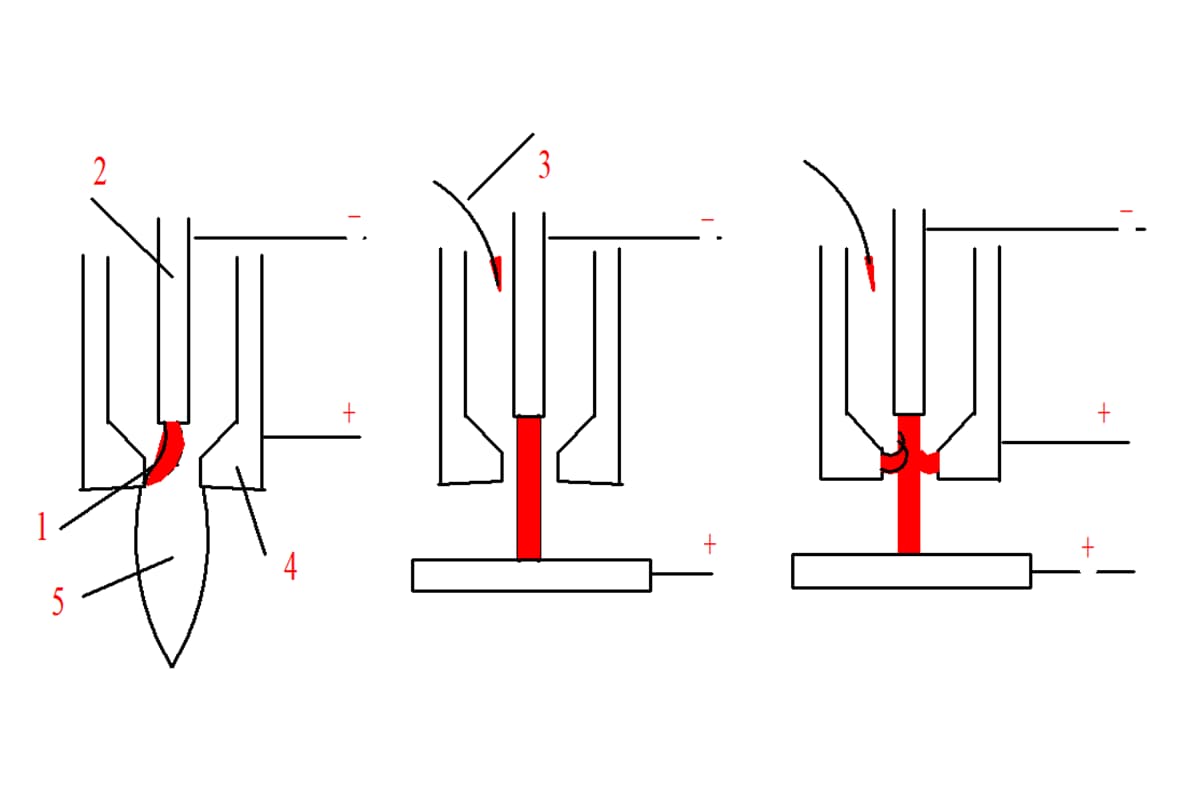

| Welding process | Welding zone | Welding material specification | Power polarity | Welding current (A) | Welding voltage (V) | Welding speed (mm/min) | Argon flow (L/min) |

| GTAW | Double sided priming | Φ2.4 | positive pole | 70~100 | 10~12 | 70~110 | 10~14 |

| SMAW | Filling cover | Φ3.2 | negative pole | 90~120 | 20~24 | 60~80 | / |

1)Argon must be at least 99.99% pure, and a product certificate must be attached to confirm its purity.

2)The recommended welding materials for various austenitic stainless steels are as follows:

| Material name | Welding wire | Filler rod |

| 0Cr18Ni9(304) | ER308 (H0Cr21Ni10) | A102 |

| 00Cr19Ni10(304L) | ER308L (H00Cr21Ni10) | A002 |

| 0Cr17Ni12Mo2(316) | ER316 (H0Cr19Ni12Mo2) | A202 |

| 00Cr17Ni14Mo2(316L) | ER316L (H00Cr19Ni12Mo2) | A022 |

| 0Cr18Ni10Ti(321) | ER347 (H0Cr21Ni10Ti) | A132 |

| 1Cr18Ni9Ti(321HTB) | ER347 (H0Cr21Ni10Ti) | A132 |

Note: Welding materials must have quality certificates or certificates with red seals.

Note: This process has been successfully piloted by relevant companies.

1)It is important to strictly control the quality of weld groove processing and weld assembly size, including clearance and unfitness.

2)The groove and heat-affected parts should be cleaned and kept dry.

3)The welding process on the main welding side is the same as that of single-sided argon arc welding. The welder on the auxiliary side must work in coordination with the welder on the main welding side and maintain the same welding speed. The wire feeding speed should be adjusted based on the shape of the weld pool and the welder’s experience to ensure that the inner wall weld looks aesthetically pleasing (on the auxiliary side).

4)The specification of the magnetic nozzle of the argon arc welding gun should be selected reasonably based on the thickness of the base metal and the size of the weld groove. The argon flow should be controlled to ensure that the weld pool and heat-affected zone are fully protected.

5)Both welders should start and extinguish the arc at the same time. After welding and extinguishing, argon should protect the arc crater for 1-2 minutes.

6)The wall panel tack welds must be mechanically cleaned before formal welding.

1)The welding quality is excellent with a high qualification rate on radiographic testing. The weld on the tank wall is also aesthetically pleasing.

2)The welding deformation is minimal, and the external weld on the tank wall is well-crafted.

3)The work efficiency has significantly improved with an increase in labor force in the same working area.

4)Construction costs have been reduced.

By eliminating the need for back welding for argon filling protection, back gouging, and polishing, argon and labor are saved.

1)The welding process has become more challenging, and it now requires welders to work together as a team to maintain a consistent welding speed.

2)Weld alignment standards are stringent, and the clearance for weld alignment is closely monitored.