Welding thick-walled titanium alloys poses significant challenges but holds immense value in industries such as aerospace and marine equipment. This article explores advanced fusion welding technologies like non-consumable electrode gas shielded welding, electron beam welding, and laser welding. It highlights their benefits, current research, and the ongoing development trends in enhancing welding quality and efficiency. By delving into these innovative techniques, the article aims to provide insights into overcoming common issues like embrittlement and welding cracks, ensuring high-performance outcomes for critical applications.

Titanium alloy is extensively utilized in aerospace, marine equipment, and other industries due to its high specific strength, excellent corrosion resistance, and high-temperature performance.

In recent years, the welding technology of thick-walled titanium alloys has gained significant application value due to the rising demand for such alloys. Thus, this paper aims to summarize the progress in fusion welding technology for thick-walled titanium alloy materials. It primarily includes non-melting electrode gas shielded welding, electron beam welding, and laser welding. Furthermore, this paper also presents an outlook on the development trend of thick-walled titanium alloy welding technology.

Related reading: Manual Arc Welding vs CO2 Gas Shielded Welding

Titanium alloy is characterized by low density, high specific strength, specific stiffness, excellent corrosion resistance, and good processability. It is a new functional material with vast development potential and promising application prospects. Known as the “third metal” after steel and aluminum, it is an essential strategic metal material, widely used in aerospace, petrochemical, national defense equipment, and other fields.

In recent years, with the increasing demand for large-scale and lightweight equipment in the national defense industry, the need for thick-walled titanium alloy has become more urgent, along with its corresponding processing technology.

In practical engineering applications, welding is the primary method used to connect thick-walled titanium alloy structures, making efficient and high-quality thick-walled titanium alloy welding technology essential and attracting considerable attention.

This article summarizes the research status of thick-walled titanium alloy fusion welding technology, identifies the existing issues with thick-walled titanium alloy fusion welding, and explores the development prospects and research directions of thick-walled titanium alloy fusion welding technology.

Titanium alloys can be classified into five categories based on their chemical composition and content: α titanium alloy, near α titanium alloy (with a β phase mass fraction of ≤10%), α-β dual phase titanium alloy (with a β phase mass fraction of 10% ≤ β ≤ 50%), metastable β titanium alloy, and β titanium alloy.

The α-β dual phase titanium alloy is widely used due to its excellent comprehensive properties. It combines the thermal stability characteristics of α-type titanium alloy with the heat treatment strengthening characteristics of β-type titanium alloy.

(1) High specific strength.

Titanium alloy is a lightweight alloy with a density of 4.54 g/cm3 at 20℃, which is about 56% of that of ordinary steel. Using titanium alloy to manufacture mechanical parts can significantly decrease the weight and achieve a lightweight effect.

(2) Good corrosion resistance.

Titanium alloy forms a stable, continuous, and dense oxide film on the surface when exposed to air, which renders it in a passive state. Additionally, the oxide film of titanium alloy has excellent repair performance. In case of damage caused by external factors, it can be promptly restored, endowing titanium alloy with remarkable corrosion resistance.

(3) High temperature performance.

The melting point of titanium alloy is 1667 ℃, which can work stably in the environment of 500~600 ℃, and has high creep resistance and heat resistance.

(1) Embrittlement of welded joint:

Without proper protection, the heating temperature of titanium alloy can trigger various chemical reactions. Hydrogen absorption begins at 250 ℃, oxygen absorption starts at 400 ℃, severe oxidation occurs at 540 ℃, and nitrogen absorption starts at 600 ℃.

These gases dissolve into the molten pool during welding and undergo chemical reactions, which can cause embrittlement of the welded joint. As a result, the plasticity and toughness of the welded joint rapidly decline. Therefore, it is crucial to protect the welding process to prevent such reactions from occurring.

(2) Welding cracks:

Titanium alloys have low levels of impurities, including S, P, C, and other contaminants. They also contain fewer low melting point eutectic compounds and have a narrow crystallization temperature range, making them less susceptible to hot cracking.

However, when welding thick-walled titanium alloys using multi-layer and multi-pass welding techniques, the welded joint is subjected to high levels of constraint stress, resulting in significant residual stress in the joint. Under the influence of this residual stress, cold cracks are easily formed.

(3) Porosity:

Porosity is a common defect that can occur during titanium alloy welding. This is due to the high saturation vapor pressure and active elements present in titanium alloy. Hydrogen porosity can occur when the surface of the base metal and welding material is contaminated, or when the shielding gas contains impurities such as oxygen, hydrogen, or water.

Gas shielded non-consumable TIG welding is widely used in the field of titanium alloys due to its benefits, such as a stable arc, less welding spatter, and good weld formation. However, the traditional TIG welding process for titanium alloys results in a longer high-temperature residence time of the welded joint and faster cooling of the liquid molten pool metal.

This is due to the low thermal conductivity of titanium alloys, which leads to a noticeable tendency for grain coarsening in the weld zone and heat affected zone.

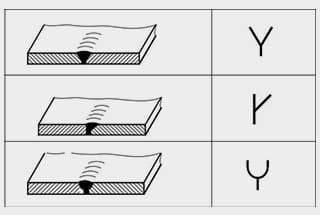

Furthermore, the large groove size necessitates multi-layer and multi-pass welding, resulting in low welding efficiency, excessive stress, and deformation. To reduce the tendency of grain coarsening, Lu Xin employed TIG welding to achieve multi-layer and multi-pass welding of 20 mm thick TC4 titanium alloy with a groove angle of 60°. Fig. 1 shows the microstructures of welded joints under different heat inputs.

As welding heat input decreases, the size of martensite inside the grains becomes smaller and more uniform, and the weld grains become progressively finer. Therefore, strict control of welding heat input is necessary when using TIG welding to weld TC4 titanium alloy thick plates to prevent coarse joint grains and avoid the occurrence of abnormal structures, cracks, and other defects.

Fig.1 Microstructure of weld zone under different heat input

Yang Lu et al. employed an X-shaped groove and alternating front and back welding to carry out multi-layer TIG welding on 24 mm thick TC4 titanium alloy, aiming to minimize residual stress and deformation in welded joints.

Simultaneously, utilizing the SYSWELD platform, the researchers conducted numerical simulations of the temperature field, stress field, and welding deformation in welded joints. The simulations were performed under the assumption of completely rigid clamping at both ends of the welding plate, as depicted in Figure 2.

The results indicated that utilizing the welding sequence of alternating two sides could significantly reduce the stress and deformation in the welded joint.

Fig.2 TEM morphology profile of welding joint residual stress thickness

In summary, while traditional TIG welding is suitable for welding thick-walled titanium alloys, the grain size, joint stress, and deformation can be minimized by reducing the welding heat input appropriately and utilizing an X-shaped groove for double-sided alternate welding.

Related reading: MIG vs TIG Welding

However, there is still a problem with large groove sizes leading to low welding efficiency, making it difficult to popularize the technique in thick-walled titanium alloy welding.

The groove size for narrow gap welding is small, resulting in a significant reduction in volume when compared to traditional groove filling welds. This reduction not only enhances welding efficiency but also reduces production costs.

Narrow gap TIG welding is a flexible process that boasts relatively low equipment costs and a stable welding process. Additionally, narrow gap grooves can reduce the number of welding passes, which in turn improves welding deformation and enables better control of welding stress.

As a result, narrow gap TIG welding for thick-walled titanium alloys offers significant advantages.

However, the small groove gap in narrow gap TIG welding can result in the arc “climbing” along the sidewall, leading to insufficient heat input at the bottom corner of both sides of the weld bead and poor fusion of the sidewall.

Currently, narrow gap TIG welding technology for thick-walled titanium alloys often employs mechanical swing and external magnetic fields to regulate the arc. These methods effectively solve the problem of poor fusion of narrow gap sidewalls.

2.2.1 Mechanical swing narrow gap TIG welding

The principle of mechanical swing narrow-gap TIG welding is as follows: during the welding process, the tungsten electrode moves back and forth within the groove by rotating the tungsten electrode clamp, which causes the arc to periodically point towards the groove’s side walls, ensuring the fusion quality of the side walls.

The welding process is depicted in Figure 3.

The mechanical swing narrow-gap welding mode is highly adaptable to changes in the welding groove’s width. It minimizes the occurrence of side wall non-fusion defects during welding, resulting in more stable welding quality. This technique has gained widespread use in the narrow-gap TIG welding of thick-walled titanium alloys.

Fig.3 Schematic diagram of mechanical swing narrow gap TIG welding process

Jiang Yongchun utilized the mechanical swing narrow gap TIG welding technique to achieve a high-quality connection of TC4 titanium alloy with a thickness of 52 mm. This was made possible through the selection of appropriate welding parameters and welding protection measures.

Figure 4 illustrates the macro metallography and microstructure of the welded joint. Due to the rapid cooling speed, α ‘martensite is formed in the heat affected zone. However, the weld strength reaches 90% of the base metal, and the hardness of the fusion zone exhibits the maximum value.

Fig.4 Macroscopic metallography and microstructure of welded joint

Li Shuang et al. utilized mechanical swing narrow gap TIG welding technology to achieve single-layer filler wire welding of 30 mm thick TC4 titanium alloy, and analyzed the microstructure of the welded joint.

The findings revealed that the grains in the weld zone were significantly coarsened, predominantly coarse columnar grains, and their microstructures consisted of acicular α’martensite, which were parallelly dispersed in the β phase grains.

The heat affected zone adjacent to the weld side exhibited a more significant degree of grain coarsening than that of the base metal side.

In conclusion, mechanical swing narrow gap TIG welding technology has a stable welding process and low equipment cost.

The periodic swing of the tungsten electrode effectively resolved the issue of inadequate fusion of the thick-walled titanium alloy sidewall.

However, due to the substantial heat input, the joint demonstrated an apparent tendency towards grain coarsening.

2.2.2 Magnetically controlled narrow gap TIG welding

The concept of magnetically controlled narrow gap TIG welding technology was first introduced by Ukraine’s Barton Welding Technology Research Institute. In recent years, the Guangdong Welding Technology Research Institute has conducted fundamental research and promoted the industrial application of this technology for thick-walled titanium alloys.

Figure 5 illustrates the welding process diagram and arc swing of magnetically controlled narrow gap TIG welding. During the welding process, the electromagnetic coil is connected to alternating current, and the silicon steel sheet passing through the coil becomes a magnet.

The magnetic induction line then passes through the electrode and the arc, resulting in a periodic swing of the arc towards the two side walls. This facilitates the fusion of the narrow gap side walls, making narrow gap TIG welding achievable.

Fig.5 Schematic illustration of external transverse magnetic field and arc swing

Scholars worldwide have conducted extensive research on the impact of magnetic field strength, magnetic field frequency, and electrode position on side wall fusion, weld formation, and crystallization process, in order to achieve high-quality welding of magnetic control narrow gap TIG welding.

Kshirsagar R et al. investigated the impact of an external magnetic field on weld formation, as illustrated in Fig. 6.

The findings indicate that there is a significant lack of fusion in the side wall when there is no external magnetic field. However, the side wall fusion is satisfactory when an external magnetic field is present.

Fig.6 Effect of external transverse magnetic field on configuration and microstructure of welding seam

(a) No external magnetic field

(b) With external magnetic field

A study conducted by Hua Aibing et al. examined the impact of external magnetic field strength on the side wall fusion of narrow gap weld. The results indicate that a magnetic field strength of ≥ 4 mT can effectively improve the side wall fusion, resulting in a relatively uniform weld fusion.

Another study by Chang Yunlong et al. investigated the effect of external magnetic field frequency on side wall fusion. The findings showed that as the magnetic field frequency increased, the penetration depth of the weld bottom and arc impact depth also increased, while the weld penetration width and side wall penetration decreased.

Yu Chen et al. conducted a study on the influence of electrode position on side wall fusion. The results revealed that when the tungsten electrode was shifted from the central position, the current inflow intensity of the near side wall increased, while the current inflow intensity of the far side wall decreased. To avoid uneven side wall penetration and poor side wall fusion, strict control of the electrode position is necessary.

Sun Jie et al. conducted a study on the influence of electromagnetic strength on the crystallization process. Figure 7 illustrates the primary crystallization of titanium alloy weld under the magnetic field’s action.

The results indicate that the electromagnetic effect can enhance the stability of the planar crystallization front area and the subsequently formed equiaxed crystals.

As the magnetic field strength increases, the microstructure near the fusion line changes gradually from columnar to equiaxed crystal. The magnetic controlled arc significantly improves the stability of the equiaxed crystal generated in the weld center. Furthermore, the equiaxed crystal grows in a single direction with an increase in magnetic field strength.

In another study, Hu Jinliang et al. used magnetic control narrow gap TIG welding technology to weld 120 mm thick TA17 titanium alloy, and Fig. 8 shows the microstructure of the welded joint. The results indicate that the joint’s microstructure displays significant inhomogeneity along the transverse direction, while no significant difference appears along the thickness direction. Due to the large welding heat input, the fusion zone is seriously softened.

Fig.7 Primary crystallization process of titanium alloy weld metal under magnetic field

Fig.8 Microstructure of 120 mm-thick TA17 titanium alloy joint welded by magnetically controlled NG-TIG welding seam

In summary, magnetic control narrow gap TIG welding technology offers a stable welding process at a lower equipment cost. By adding a magnetic field, the technology enables periodic arc swinging, which effectively resolves the poor fusion problem associated with thick-walled titanium alloy side walls and results in a uniform weld zone structure.

Nevertheless, the technology still faces a significant challenge of softening the fusion zone of welded joints due to the high heat input. Narrow gap TIG welding, on the other hand, can achieve stable welding of thick-walled titanium alloy. This technology reduces the number of welding passes and improves welding efficiency compared to traditional TIG welding.

However, narrow gap TIG welding also has its issues. Due to the repeated remelting and heating of joint grains, it causes problems such as coarse grains and uneven distribution of microstructure and properties along the thickness direction.

Submerged arc welding is a distinct form of welding, separate from TIG welding.

This method uses helium as a shielding gas, and the electrode diameter and welding current are both large.

Through a combination of helium and arc force, it is capable of draining the liquid molten pool metal at the weld position.

The electrode submerges into the base metal to be welded, and the arc burns in the electrode and the cavity formed at the bottom of the crater, ultimately resulting in the formation of the molten pool.

Due to the arc burning position being below the surface of the base metal, it is referred to as submerged arc welding.

The principle of submerged arc welding can be seen in Figure 9.

Fig.9 Schematic graph of SAW principle

In recent years, scholars have conducted research on the application of submerged arc welding technology to large-thickness titanium alloys.

Chen Guoqing and colleagues carried out a butt test using submerged arc welding on a 29 mm thick TA15 titanium alloy and obtained well-formed welds.

However, due to the high heat input, the welded joint’s weld zone and heat-affected zone are relatively wide, and the joint’s elongation after fracture is only 50% of the base metal.

The welded joint’s bending property is poor, and it breaks when it bends to 15 °.

Liu Yanmei and others accomplished the welding of a 58 mm thick TA15 titanium alloy by using a double-sided submerged arc welding process.

The macro section of the weld is shown in Fig. 10. The weld zone has columnar crystals with large grain size, and the intragranular is acicular α’martensite.

The joint’s tensile fracture location is the weld zone, which is a ductile fracture.

The tensile strength reaches 96% of the strength of the base metal.

To improve the mechanical properties of the submerged arc welding joint, Duqiang et al. conducted submerged arc welding of a 64 mm thick TA15 titanium alloy plate with the addition of TA1 pure titanium interlayer.

The results showed that the hydrogen, oxygen, and nitrogen contents in the weld, after adding the interlayer, were reduced compared to the base metal, and the welded joint’s plasticity was significantly improved.

Hou Qi et al. studied the effect of shielding gas purity on the performance of a TA15 titanium alloy plate submerged arc welding joint.

The results showed that the mechanical properties of the welded joint could be improved to some extent by increasing the shielding gas purity.

Fig.10 Macroscopic cross section of weld

In summary, submerged arc welding is capable of welding thick-walled titanium alloys with a relatively stable arc shape, resulting in better weld formation. Helium is typically used for coaxial protection in submerged arc welding because of its high ionization potential and high thermal conductivity when compared with argon.

As a result, the arc column area in submerged arc welding is narrow and concentrated, leading to a high utilization rate of arc heat. This welding technique can perform double-sided welding of thick titanium alloys, significantly improving welding efficiency when compared to narrow gap TIG welding.

However, there are some issues associated with this method, such as excessive heat input, coarse grain structure, and uneven distribution of microstructure and properties in the thickness direction.

Non-consumable inert gas arc welding is capable of welding thick titanium alloys with a relatively stable arc shape, resulting in better weld formation. This technique demonstrates high application value in thick titanium alloy welding research.

However, there are still issues such as joint softening caused by a high welding heat input. Therefore, it is crucial to conduct research on reducing the heat input during the welding of thick plate titanium alloys. This can improve the homogeneity of the structure and properties of non-MIG welded thick wall titanium alloys.

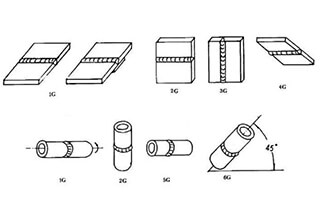

Electron beam welding technology utilizes high-energy density electron beams to bombard metal materials, enabling the single-sided welding and double-sided forming of thick metal materials.

During the welding process, the beam power density is high, resulting in a large depth-width ratio of the weld and minimal welding deformation.

Furthermore, electron beam welding must be performed in a vacuum environment, which effectively prevents the negative effects of hydrogen, oxygen, and nitrogen during the welding process. As a result, electron beam welding is commonly used for welding large thickness titanium alloys.

Figure 11 shows the electron beam welding device.

Fig.11 Schematic of the electron beam welding

Domestic and foreign scholars have studied the microstructure and properties of vacuum electron beam welded joints of titanium alloys.

Hou Jiangtao utilized electron beam welding technology to weld 20 mm thick TC4 titanium alloy, analyzed the grain size of the weld zone, and the mechanical properties of the joint along the thickness direction.

The results revealed that the upper part of the weld zone had a grain size of 1200 µm, while the lower part had a grain size of 200 µm, leading to differences in properties.

Sun et al. also used electron beam welding technology to weld 20 mm thick TC4 titanium alloy and analyzed the macro morphology of the welded joint (see Fig. 12).

The fusion zone and heat-affected zone in the upper, middle, and lower areas of the welded joint had significantly different widths, as well as differences in the morphology and size of the grain structure, which decreased along the depth direction.

Wei Lu et al. welded 50 mm thick TC4 titanium alloy plates using electron beam welding technology and carried out mechanical property tests along the thickness direction. The results revealed that the mechanical properties were distributed unevenly along the welding depth.

The yield strength, tensile strength, and microhardness of the welded joint improved compared to those of the base metal, while the plasticity and toughness decreased.

Finally, Song Qingjun utilized electron beam welding technology to weld TC4 titanium alloy with a thickness of 60 mm and analyzed the microstructure and properties of the welded joint. The results showed that the microstructure of the welded joint was distributed unevenly along the thickness direction, and the impact toughness gradually decreased from the top to the bottom of the weld.

Fig.12 Macroscopic appearance of welded joint

In summary, during the electron beam welding of thick-walled titanium alloys, the weld metal undergoes a rapid thermal cycle process, which results in uneven distribution of microstructure and properties in different areas along the thickness direction due to inconsistent residence times at high temperatures.

To address the issues of non-uniform distribution of microstructure and properties and low mechanical properties in thick-walled titanium alloy electron beam welded joints, relevant researchers have optimized the welding process and conducted post-weld heat treatment to adjust the microstructure and properties of the joints.

Gong Yubing et al. conducted an extensive study on the non-uniformity of the electron beam welded joint of 20mm thick TC4 titanium alloy and the structure’s evolution. Figure 13 shows the microstructures of different areas of the welded joint.

The results indicate that the titanium alloy weld joint has a significant non-uniformity in the direction of fusion width and penetration depth. The average grain size of the upper weld joint is larger than that of the middle and lower parts.

Widmanstatten structure appears in the upper and middle parts of the weld joint, increasing the brittleness of the joint and decreasing its plasticity. When using large heat input welding, the non-uniformity of microstructure distribution can be improved.

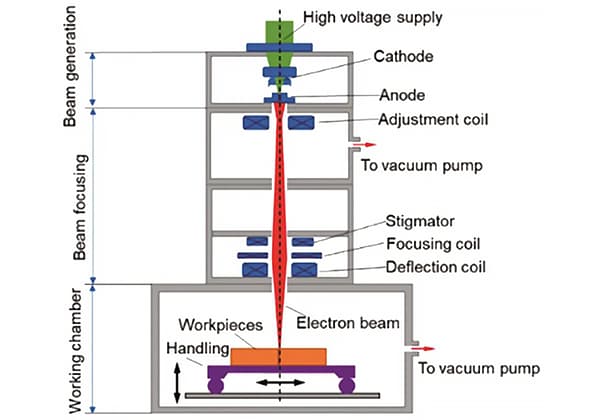

Li Jinwei et al. achieved uniformity control of 20 mm thick TA15 titanium alloy electron beam weld composition by applying scanning waveforms of certain frequency and deflection amplitude to the electron beam during welding, embedding transition metal materials in the welding interface, and adjusting welding parameters.

Figure 14 shows the control effect of weld composition uniformity under different process conditions. Compared with traditional electron beam welding, scanning electron beam welding results in less fluctuation of alloy elements in the thickness direction, leading to more uniform composition.

Fig.13 Microstructure of different regions of welded joint

Fig.14 Uniformity control effect of weld composition under different process conditions

Fang Weiping et al. utilized electron beam welding technology to weld 100 mm thick TC4 titanium alloy plates. The resulting welded joints were subjected to recrystallization annealing at 850 ℃ and solution aging heat treatment at 920 ℃×2 h and 500 ℃×4 h.

The results revealed that the microhardness of the weld zone, heat-affected zone, and base metal zone obtained through solution aging heat treatment was higher than that of the as-welded state. Moreover, the tensile strength of the welded joint was 11.3% higher than that of the as-welded state, and the yield strength was 17.2% higher than that of the as-welded state. However, the elongation after fracture was only about 50% of that of the as-welded state.

Ma Quan et al. investigated the impact of heat treatment processes on the microstructure and mechanical properties of electron beam welded joints of Ti-1300 alloy. The outcomes showed that different heat treatments before welding had little effect on the microstructure and properties of the titanium alloy weld. In contrast, post-weld heat treatment processes could not alter the shape and size of the β grain in the weld zone but could regulate the content, size, and shape of the a phase in the weld zone. However, the distribution of the precipitated a phase tended to form at the stable grain boundary.

The performance of the weld zone depended on the size and number of the precipitated α phase. When annealing or aging at a lower temperature alone, the strengthening effect of the α phase in the weld zone was better, and the weld strength was higher than that of the base metal.

In summary, appropriate welding heat input combined with a swinging electron beam could somewhat improve the inhomogeneity of microstructure and properties of welded joints. Moreover, post-weld heat treatment could enhance the mechanical properties of welded joints.

Welding residual stress is a critical factor that can lead to stress corrosion and reduction in fatigue strength of structural components.

An accurate assessment of welding residual stress is crucial to determine the lifespan of welded components.

Liu Min and colleagues analyzed the residual stress distribution of an electron beam specimen made of 75 mm thick TC4 titanium alloy, based on the thermal elastoplastic finite element theory.

Fig. 15 presents the results of the residual stress test.

The findings indicate that there is a three-dimensional residual tensile stress with high value in the area located 10 mm from the starting and ending ends, covering about 1/4 of the thickness. This stress can significantly affect the mechanical properties of welded joints, and hence requires adequate attention.

Fig.15 Calculation results of residual stress

Wu Bing et al. conducted a study on reducing residual stress in welded joints by measuring the residual stress distribution of 50 mm thick TA15 titanium alloy electron beam welded joints after vacuum annealing using the blind hole method. The results showed that the heat treatment process made the transverse and longitudinal stresses of welded joints more consistent, and the stress of the whole welded joint became more uniform.

Similarly, Yu Chen et al. measured the residual stress distribution of 100 mm thick TC4 titanium alloy electron beam welded joints after 600 ℃×2 h heat treatment by X-ray diffraction. The results demonstrated that heat treatment reduced the residual stress of the welded joint to some extent, and the distribution on the upper and lower surfaces of the welded joint was noticeably different.

The horizontal and longitudinal residual stresses on the upper surface decreased, and the longitudinal residual stress in some areas changed from tensile stress to compressive stress. The longitudinal residual stress on the lower surface was effectively eliminated, and some positions were in a compressive stress state. The horizontal residual stress relief effect was average.

Additionally, Hosseinzadeh F et al. used the contour method to measure the distribution of residual stress in electron beam welded joints of 50 mm thick TC4 titanium alloy after heat treatment. The results showed that the maximum tensile stress at the initial end of the weld was 330 MPa, the maximum compressive stress was 600 MPa within 10 mm of the rear end of the test plate, and the tensile stress at the weld centerline after heat treatment could be reduced to 30 MPa.

In summary, post-weld heat treatment can significantly reduce the residual stress of thick-walled titanium alloy welded joints.

In summary, electron beam welding is capable of achieving high welding efficiency and producing welded joints with minimal deformation and good shape when welding thick-walled titanium alloys. However, due to the narrow melting area and large temperature gradient, thermal cycling can lead to the formation of triaxial stress in the structure, resulting in a sharp decrease in joint plasticity and toughness.

Although an appropriate heat treatment process can partially enhance the structure and performance of the welded joint, it has not been entirely resolved. Hidden dangers remain for later service work, such as uneven structure, performance, and stress distribution along the thickness direction. Furthermore, the heat treatment process not only increases production costs but also reduces production efficiency.

Additionally, the vacuum chamber also limits the application of electron beam welding to large titanium alloy components. Therefore, research should be conducted on the microstructure, properties, and stress distribution uniformity of welded joints, particularly in the direction of local vacuum electron beam welding.

After decades of development, laser welding technology has made significant progress. With the birth of fiber lasers and the development of photoelectric modules, the output power of lasers has increased, and beam stability has improved, laying a solid foundation for its application in the field of thick wall component welding.

Compared to traditional thick wall arc welding technology, laser welding offers high welding efficiency, minimal welding deformation and residual stress, narrow heat affected zones, and excellent adaptability for welding large and complex structures.

These advantages have made laser welding technology one of the main research focuses for thick wall component welding in recent years.

Currently, laser welding technology for thick-walled titanium alloys includes laser filler wire welding and vacuum laser welding.

Narrow-gap laser welding with filler wire involves using a wire feeding mechanism to push the filler metal to the laser focus spot. The melted filler metal then fills the weld through the action of the laser beam, ultimately completing the welding process.

Figure 16 illustrates a schematic diagram of narrow-gap laser welding with filler wire. This technique has experienced rapid development in recent years.

Despite its progress, narrow-gap laser welding with filler wire still faces some challenges, particularly when dealing with thick-walled titanium alloy welding. Such issues may include lack of fusion of the side wall, welding porosity, welding deformation and high stress, and poor plastic toughness of welded joints.

Fig.16 Schematic diagram of narrow gap laser wire-filling welding

Li Kun et al. used a swinging laser beam to suppress porosity in titanium alloy and analyzed its mechanism in order to solve the problem of side wall non-fusion and welding porosity.

The results showed that the swinging beam had a significant effect on reducing the porosity of titanium alloy keyhole welding. This was due to the increased stability of the keyhole during welding, resulting in a reduction in keyhole porosity.

Xu Kaixin et al. used a laser beam circular swing to weld 40 mm thick TC4 titanium alloy. When the swing amplitude was 2 mm and the swing frequency was 100-200 Hz, the weld seam had no visible pores, and the side wall was well fused.

Analysis of the microstructure and properties of the welded joint showed that the columnar crystal of the weld seam contained densely arranged acicular α’martensite and dispersedly distributed granular αg phase. The α’ preferred orientation was found in the same β grain, and the proportion of large-angle grain boundaries was high. The welded joint exhibited high strength, but poor plasticity and toughness.

In conclusion, a swinging laser beam is an effective solution for the problems of side wall non-fusion and welding porosity.

Fig.17 Morphology and microstructure of narrow gap section of 40 mm thick TC4 titanium alloy

To address the poor plasticity and toughness of thick-walled titanium alloy welded joints, researchers have enhanced the microstructure and properties of welded joints by regulating the welding heat input and weld alloy elements.

Fang Naiwen and colleagues investigated the impact of welding heat input on TC4 titanium alloy laser welding with filler wire. Their findings indicated that appropriate welding heat input could ensure good plasticity in the weld joint.

Additionally, using the high-temperature laser confocal microscope’s in-situ observation method, they analyzed the microstructure formation characteristics and transformation laws of the self-developed Ti-Al-V-Mo series titanium alloy during the cooling process under the welding thermal cycle. The results demonstrated that adding Mo decreased the initial transformation temperature, decreased the aspect ratio of acicular α ‘martensite and initial α phase, and enhanced the impact toughness of welded joints.

Therefore, by controlling the heat input in the welding process and designing the alloy element ratio of metal powder cored flux cored wire reasonably, the plastic toughness of the welded joint can be improved.

The process of ultra-narrow gap laser filler wire welding of thick titanium alloy plate is the result of heat accumulation from a single pass of multi-layer filler metal. The multiple thermal cycles in the process of multi-layer welding will inevitably create an extremely complex weld structure with an uneven temperature field.

During welding, the welded joint may experience uneven distribution of residual stress and welding deformation. Additionally, titanium alloy has a high linear expansion coefficient and low thermal conductivity, which further increases the likelihood of welding residual stress and welding deformation.

The negative impact of welding residual stress on the static load strength, low cycle fatigue strength, and corrosion resistance of titanium alloy welded joints is significant. Furthermore, welding deformation can significantly affect the appearance of welded joints, reduce the bearing capacity of the structure, and lower the assembly accuracy of later welding components.

To gain deeper insights into the influence of groove forms on the residual stress of welded joints, Fang Naiwen et al. used ANSYS simulation software to perform numerical simulation analysis on the stress and strain of different groove forms of 40 mm thick TC4 titanium alloy laser welded joints.

Figure 18 depicts the longitudinal stress distribution of the two groove forms. The results indicate that the stress distribution of single U-groove welded joint differs from that of double U-groove welded joint. In single U-groove welded joint, an obvious stress concentration appears on one side of the end weld, while the stress distribution of double U-groove welded joint is symmetrical along the wall thickness direction.

Fig.18 Longitudinal residual stress distribution stress distribution

In summary, narrow gap laser welding with filler wire is capable of producing thick-walled titanium alloy welded joints without welding defects like porosity and incomplete fusion of the side wall by periodically oscillating the laser beam.

The plastic toughness of the welded joint can be improved by controlling the heat input in the welding process and the alloy element ratio of the metal powder-cored wire.

However, in the domain of thick-walled titanium alloy narrow gap laser welding with filler wire, it is essential to continue exploring the control of the microstructure and properties of welded joints, especially in the realm of laser-filled metal-cored flux-cored wire with a multi-alloy system.

In recent years, high-power industrial fiber lasers have reached the level of 10,000 watts. However, efficiently using high-quality, high-power lasers and improving the penetration ability of laser welding without sacrificing its quality is a difficult problem in engineering applications.

Recent research has shown that penetration depth can be significantly increased in a vacuum environment, improving the porosity of the weld and its formation. Reisgen U from the Technical University of Aachen, Germany compared the penetration ability of laser welding, vacuum laser welding, and electron beam welding.

Results showed that under the same line energy, the weld penetration obtained by laser welding in a vacuum environment is about 2.5 times higher than that in an atmospheric environment and is similar to that obtained by electron beam welding. However, the vacuum required for laser welding in a vacuum environment is only 10 Pa, while electron beam welding requires at least 10-1 Pa, making the cost of vacuum laser welding lower.

Therefore, scholars have carried out research on low vacuum laser welding technology for thick wall structures. Meng Shenghao et al. studied the vacuum environment laser welding characteristics of TC4 titanium alloy for medium and thick plates.

The results showed that vacuum environment laser welding has better weld formation, significantly improves weld penetration, increases the weld depth-width ratio, inhibits spatter in the welding process, and greatly reduces gas hole defects in the weld.

Harbin Welding Research Institute Co., Ltd. achieved the welding of 40 mm thick TC4 alloy using low vacuum (vacuum degree 10 Pa) laser welding technology. They compared and analyzed the microstructure and mechanical properties of different positions.

The macro morphology of the welded joint is shown in Fig. 19. The results showed that the microstructure of the heat-affected zone is α phase, residual β phase, and α’ martensite.

The microstructure of the weld melting zone mainly includes α’ martensite of different sizes and distribution states and α phase formed at low cooling rate. The tensile properties along the thickness direction are uniform, and the strength values at the top and bottom are larger, while the strength values at the middle upper part and middle lower part are smaller, but the overall difference is small.

Fig.19 Macromorphology of 40 mm thick titanium alloy welded joint

In summary, vacuum laser welding enables the welding of thick-walled titanium alloys. This welding process boasts several advantages over electron beam welding, including lower vacuum requirements, no radiation pollution, lower welding costs, and higher efficiency. As a result, vacuum laser welding represents a promising method for welding thick-walled titanium alloys.

Despite these advantages, there is still a need for further research by relevant scholars in the field of low vacuum laser welding of thick-walled titanium alloys. Specifically, there should be an in-depth investigation into the characteristics of laser energy transmission under vacuum conditions and the control of welding joint microstructure and properties.

This article primarily discusses the progress made in fusion welding technology for thick wall titanium alloy welding, aimed at meeting the requirements of high-quality welding and manufacturing of aerospace, marine equipment, and other related fields.

Over the past decade, significant advancements have been made in fusion welding technology for thick walled titanium alloys. These achievements encompass various areas such as welding technology, quality control, joint structure, and property control.

Combined with the current research status, the fusion welding of thick walled titanium alloys mainly has the following research directions:

(1) Stress control of thick wall titanium alloy welding.

Due to the small thermal conductivity and large linear expansion coefficient of titanium alloy, three-way stress can easily form in the structure after thermal cycling during the welding process of thick-walled titanium alloy. This can result in a sharp decline in the plasticity and toughness of the joint.

To address this issue, various techniques can be employed, such as post-weld heat treatment, groove optimization design, and ultrasonic impact treatment, depending on the welding method used. These techniques can help to control the stress and strain of thick-walled titanium alloy welded joints.

(2) Development of multi heat source welding technology.

Currently, fusion welding technology for thick-walled titanium alloy mainly involves single heat sources such as conventional arc welding, electron beam welding, and laser welding. However, these welding methods have certain limitations.

Therefore, to address these limitations, the development of multi-heat source welding technology such as TIG-MIG hybrid welding and laser arc hybrid welding can be pursued for thick-walled titanium alloy welding.

(3) Control of microstructure and properties of welded joints.

Currently, there is limited research on controlling the microstructure of welded joints in thick-walled titanium alloys.

However, it is feasible to develop welding materials with multi-alloy systems and regulate the microstructure of the welds. This can potentially enhance the mechanical properties of thick-walled titanium alloys.