What makes one welding method better than another? This article explores the unique advantages and disadvantages of seven welding techniques, from Tungsten Inert Gas (TIG) to Manual Shielded Metal Arc Welding. Each method’s efficiency, cost, and suitability for different materials and thicknesses are examined, helping you understand which approach might be best for your specific project needs. Dive in to learn how each method stacks up in terms of productivity, quality, and practical application.

(1) The argon gas effectively isolates the air and is itself insoluble in metal, does not react with metal, and during the welding process, the arc can automatically clear the oxide film on the surface of the molten pool. Therefore, it can successfully weld easily oxidized, nitrified, chemically active non-ferrous metals, stainless steel, and various alloys.

(2) The tungsten electrode arc is stable and can still burn stably at very low welding currents (less than 10A), making it particularly suitable for welding thin sheets and ultra-thin materials.

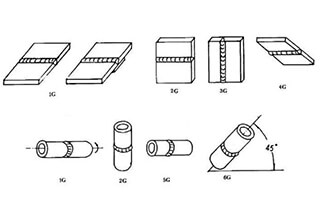

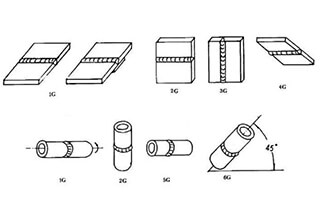

(3) The heat source and filling wire can be controlled separately, so the heat input is easy to adjust, and various position welding can be carried out. It is also an ideal method for achieving single-side welding and double-side forming.

(4) Since the filling wire droplets do not pass through the arc, there is no spatter and the weld seam is beautiful.

(1) The depth of the weld seam is shallow, the deposition rate is low, and the productivity is relatively low.

(2) The tungsten electrode has poor current carrying capacity. Excessive current can cause tungsten melting and evaporation, and its particles may enter the molten pool, causing contamination (tungsten inclusion).

(3) Inert gases (argon, nitrogen) are relatively expensive, and compared with other arc welding methods (such as manual arc welding, submerged arc welding, carbon dioxide gas shielded welding, etc.), the production cost is higher.

Note: Pulsed Tungsten Inert Gas Welding is suitable for welding thin plates, especially full-position butt welding. Tungsten Inert Gas Welding is generally only suitable for welding workpieces with a thickness of less than 6mm.

(1) Like TIG welding, it can weld almost all metals, especially suitable for welding materials such as aluminum and aluminum alloys, copper and copper alloys, and stainless steel.

(2) Since the welding wire acts as an electrode, a high-density current can be used, so the base metal has a large penetration depth, and the filling metal has a fast deposition rate. When used for welding thick aluminum plates, copper, and other metals, the productivity is higher than that of TIG welding, and the welding deformation is smaller than TIG welding.

(3) Consumable electrode argon arc welding can be DC reverse connection, which has a good cathodic sputtering effect when welding aluminum and its alloys.

(4) The inherent regulation effect of the subsonic arc is more significant when welding aluminum and its alloys with consumable electrode argon arc welding.

MIG welding usually uses inert gas (argon, helium or their mixture) as the shielding gas in the welding zone.

(1) Inert gas almost does not react with any metal and is insoluble in metal, so it can weld almost all metals.

(2) The welding wire has no coating layer, and the welding current can be increased, so the base metal has a large penetration depth, the welding wire has a fast melting speed, and the deposition rate is high. Compared with TIG (Tungsten Inert Gas Arc Welding), its production efficiency is high.

(3) Jet transition is mainly used for droplet transition. Short-circuit transition is only used when welding thin plates, while droplet transition is rarely used in production. When welding aluminum, magnesium, and their alloys, subsonic arc transition is usually used because the cathode sputtering region is large, the molten pool protection effect is good, and the weld seam is well-formed with fewer defects.

(4) If short-circuit transition or pulse welding method is used, full-position welding can be carried out, but its welding efficiency is lower than that of flat welding and horizontal welding.

(5) Generally, DC reverse connection is used, so the arc is stable, the droplet transition is uniform, and the spatter is small, and the weld seam is well-formed.

(1) Inert gas is expensive, and the cost is high.

(2) It is sensitive to oil and rust on the base metal and welding wire and is prone to generate pores.

(3) Compared with CO2, its penetration depth is smaller, and its wind resistance is weak, so it is not suitable for outdoor welding.

(1) The CO2 arc has strong penetration, and can increase the blunt edge of the groove and reduce the groove when welding thick plates; the welding current density is large, and the melting rate of the welding wire is high. Generally, there is no need to clean up slag after welding, so the productivity of CO2 welding is about 1-3 times higher than that of stick arc welding.

(2) Pure CO2 welding cannot achieve jet transition within the general process range. Short-circuit transition and droplet transition are commonly used. It is possible to obtain jet transition only after adding a mixed gas.

(3) Short-circuit transition can be used for full-position welding and has high welding quality for thin-walled components with small welding deformation. Because the arc heat is concentrated, the heated area is small, the welding speed is fast, and the CO2 airflow plays a certain cooling role in the weldment, which can prevent burn-through of the welded parts and reduce welding deformation.

(4) It has strong rust resistance, low hydrogen content in the weld seam, and less tendency to cold crack when welding low-alloy high-strength steel.

(5) The price of CO2 gas is cheap, the cleaning of the weldment before welding can be simplified, and its welding cost is only 40%-50% of submerged arc welding and stick arc welding.

(1) During the welding process, there is more splatter of metal, especially when the welding process parameters are not matched properly, it can be more severe.

(2) The arc atmosphere has strong oxidizing properties and cannot weld easily oxidizable metal materials. Its wind resistance is weak, and outdoor operations require wind protection measures.

(3) The welding arc is strong, especially when welding at high current, attention should be paid to protecting the operators from arc radiation.

(1) High welding productivity

a. There is no limit to the decomposition of coating components, so much higher currents can be used compared to stick arc welding;

b. Due to the insulating effect of the flux and slag, the welding speed of submerged arc welding is greatly improved.

(2) Good welding seam quality

a. Protected by flux and slag;

b. The gas has a reducing property;

c. More time for metallurgical reactions reduces the possibility of defects such as porosity and cracks in the weld seam; d. Welding parameters can be kept stable through automatic adjustment.

(3) Lower welding cost

a. The large welding current used in submerged arc welding can make the weldment have a larger penetration depth;

b. Very little metal spatter; c. The heat of submerged arc welding is concentrated, with high thermal efficiency.

(4) Good labor conditions

a. Mechanization;

b. Improved working conditions for welders.

(5) Wide range of welding applications.

(1) Difficult to weld in spatial positions.

(2) High requirements for the assembly quality of welded parts.

(3) Not suitable for welding thin plates and short welds.

(1) The two metals are welded from the inside under pressure in resistance welding, and the metallurgical problems in the welding point formation process or joint surface formation process are simple. Therefore, there is no need for flux or gas protection during welding, nor do you need to use filler metals such as welding wire or electrodes to obtain a good quality welded joint with a low welding cost.

(2) Due to the concentrated heat and short heating time, the heat-affected zone is small, and the deformation and stress are also small. Usually, there is no need to consider correction or heat treatment after welding.

(3) Simple operation, easy to achieve mechanization and automated production, no noise or dust, and good working conditions.

(4) High productivity, it can be combined with other manufacturing processes into assembly production lines in large-scale production. Only flash butt welding requires appropriate isolation due to spark splashes.

(1) Currently, there is a lack of reliable non-destructive testing methods, and the welding quality can only be checked by process samples and destructive testing, as well as various monitoring techniques to ensure it.

(2) Spot welding and seam welding require overlap joints, which increase the weight of the components, and the tensile and fatigue strength of the joints are relatively low.

(3) The equipment has high power and a higher degree of mechanization and automation. Therefore, the equipment investment is large, and maintenance is more difficult. High-power welding machines have difficulty in feeding the power grid load. If it is a single-phase AC welding machine, it will have an adverse effect on the normal operation of the power grid.

Note: Resistance welding is suitable for a wide range of materials. It can not only weld low carbon steel but also various alloy steels, as well as non-ferrous metals such as aluminum, copper, and their alloys.

(1) Relatively simple equipment is used for manual shielded metal arc welding, which is relatively cheap and light. Both AC and DC welding machines used in shielded metal arc welding are relatively simple, and no complex auxiliary equipment is required during welding operations, only simple tools are needed. Therefore, the investment in equipment for purchasing welding rods is small, and maintenance is easy, which is one of the reasons for its wide application.

(2) No gas protection is required. The welding rod not only provides filler metal but also produces gas to protect the molten pool and prevent oxidation during the welding process, and it has strong wind resistance.

(3)Flexible operation and strong adaptability. Shielded metal arc welding is suitable for welding single pieces or small batches of products, short or irregular welds, spatial positions, and other welds that are not easy to achieve mechanized welding. Welding can be performed wherever the welding rod can reach.

(4) Wide range of applications, suitable for welding most industrial metals and alloys. Appropriate welding rods can not only weld carbon steel and low-alloy steel but also high-alloy steel and non-ferrous metals. It can not only weld the same metal but also different metals, as well as repair cast iron and various metal materials such as surfacing.

(1) High requirement for the welding operator’s skills, and high training costs. The welding quality of shielded metal arc welding mainly depends on the welding operator’s operation skills and experience, in addition to using appropriate welding rods, welding process parameters, and welding equipment. Therefore, regular training of welding operators is necessary, which incurs significant training costs.

(2) Poor working conditions. Shielded metal arc welding mainly relies on manual operation and visual observation, which can lead to high labor intensity for welding operators. Additionally, the welding process involves high-temperature baking and toxic fumes, leading to poor working conditions that require stronger labor protection measures.

(3) Low production efficiency. Shielded metal arc welding mainly relies on manual operation, and welding rods need to be frequently replaced during welding. Additionally, slag cleaning needs to be performed regularly, resulting in a lower welding production rate than automatic welding processes.

(4) Suitable for special metals and thin plates. For highly reactive metals (such as Ti, Nb, Zr, etc.), and refractory metals (such as Ta, Mo, etc.), the protection of welding rods is not sufficient to prevent oxidation of these metals, which may result in poor welding quality. Furthermore, low-melting-point metals such as Pb, Sn, Zn, and their alloys are not suitable for shielded metal arc welding due to the high temperature of the arc. Additionally, the thickness of the welded workpiece for shielded metal arc welding is generally above 1.5mm, and it is not suitable for welding thin plates below 1mm using this method.