How much do you really know about laser cutting technology? This nine-question quiz challenges your understanding of key concepts and techniques, from the dynamics of the flying light path to the intricacies of different cutting methods like fusion and vaporization. By the end, you’ll have a clearer grasp of how laser cutting machines work and the safety precautions necessary for their operation. Dive in and test your knowledge to see if you’re up to speed with this cutting-edge technology.

Generally, to ensure stability of the output, the laser generator is fixed, which results in a relatively fixed laser transmission direction. However, to meet various demands, means to change the laser transmission direction are often employed, making the laser transmission dynamic.

Common methods include the use of reflectors and optical fibers.

The light source remains stationary, while the reflector and focus lens move, allowing for a stable power output to be maintained. This results in a dynamic light path.

The cutting techniques are shown as follows:

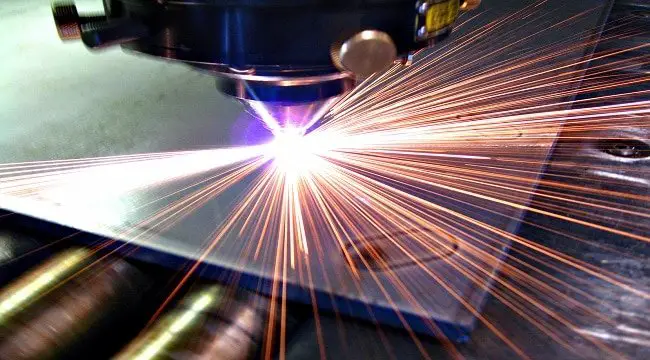

The Fusion Cutting process involves shining a laser light onto a plate, causing partial areas to melt and achieve the cutting effect when the laser power reaches a critical value.

In Vaporization Cutting, high-powered laser beams are utilized to heat the material, preventing the formation of slag burrs that result from heat conduction during melting. This process results in a relatively clean edge, as some materials are vaporized into steam.

Oxidation Cutting involves using the heat generated from the chemical reaction between the oxygen blown out from the nozzle and the laser beams to perform the processing. This method is suitable for brittle materials that can be easily damaged by heat, as they can be cut at a high speed using the laser beams.

However, this process can also result in an obvious thermal gradient and severe mechanical deformation, causing materials to crack. As a result, Oxidation Cutting is also referred to as Controllable Fracture Cutting.

There are:

Autofocus System Technology: The smaller the focal depth, the smaller the diameter of the laser direct focus. Therefore, precise control of the focus is crucial for cutting the surface of materials.

Cutting and Drilling Technology: In any type of cutting processing technology, except for cutting from the edge, there is a commonly known position referred to as “the knife” on the cutting material. This position involves drilling first, followed by subsequent cutting.

Nozzle Design and Airflow Technology: When using a laser to cut materials, airflow is generated in the nozzle, typically using “air”, “nitrogen”, or “oxygen”. This not only improves the cutting speed and appearance, but also helps to remove slag, achieving two goals with one action.

In my opinion, there are:

Because laser beams are invisible to the human eye, it is important not to stare at them for extended periods of time, as this can be dangerous. Additionally, the focus lens of a laser cutting machine contains harmful elements such as ZnSe, so it is recommended to avoid frequent contact and to have scrap lenses disposed of professionally rather than simply throwing them away.

It is safe to process materials such as carbon steel or iron using the laser cutting machine. However, if a large amount of aluminum alloy or other alloys are being processed, it is important to wear a mask to protect against inhaling the cutting dust. Due to the strong reflection of aluminum plates, a protective device has been added to the laser head to prevent injury.

In general, there are potential hazards associated with any job, but the risk of harm can vary. No job is completely safe and the level of danger is often relative.

For instance, laser cutting is considered to be more environmentally friendly compared to plasma and flame cutting. Plasma cutting machines emit a large amount of dust, smoke, and bright light, requiring the use of dust removal equipment.

On the other hand, laser cutting machines produce less dust, emit less intense light, and generate minimal noise, making them more eco-friendly.

However, it’s important to note that new laser cutting machine operators may be inclined to stare at the cutting head, which can cause eye strain and discomfort if done for an extended period of time. To mitigate this risk, some manufacturers may provide protective glasses for the operator.

Additionally, laser cutting machines are highly advanced and can be operated without human intervention, reducing the need for operators to stare at the cutting head.

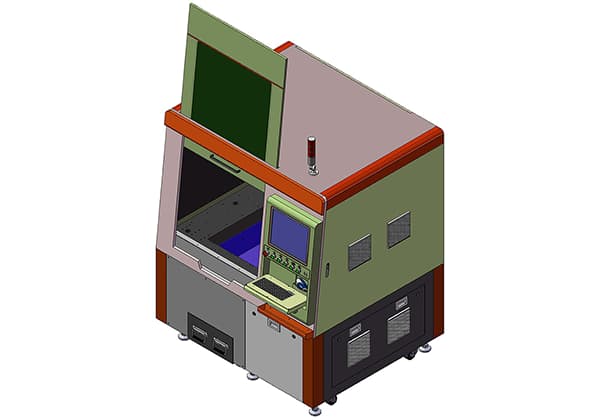

In terms of structure, laser cutting machines are divided into:

This type of laser cutting machine is commonly seen. The laser is positioned on one side and transferred through the external light path to the laser cutting head, with a machining area of 1.5 x 3 meters or 2 x 4 meters.

Based on its specific design, bench laser cutting machines can be categorized into several types, including cantilever, gantry, and hybrid types. These machines are primarily used for processing sheet metal and are utilized in a variety of industries, including medical equipment, lamp ornaments, food machinery, and others that require thin plate processing.

This type of laser cutting machine uses a laser that moves with the operation of the machine, which ensures a consistent light path.

It has a large cutting range, with a width of 2-6 meters and a length of dozens of meters. It is primarily used in the construction machinery, shipbuilding, locomotive, and other heavy industries.

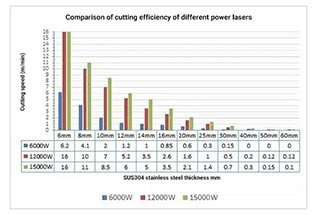

It is designed for cutting plates with a thickness of 3mm-25mm.

In terms of cutting material, it is simply divided into three types:

The power of the laser is very large, ranging from 500 watts to 3000 watts or higher, which is used for cutting carbon steel, stainless steel, copper, aluminum, alloy steel and other metal materials

The power of the laser is generally small, mainly used for cutting acrylic, leather, cloth and other non-metallic materials.

There are four points:

In most instances, air, oxygen, or nitrogen are utilized. The primary aim is to remove residue and attain the optimal cutting outcome.

When utilizing gases to clear away metal slag, it can safeguard the lens and prevent the slag from impacting the cutting quality by preventing it from adhering to the lens.

Cutting with nitrogen results in a smooth cutting surface with no burrs or slag, which can be referred to as fine cutting.

When cutting with oxygen, it can aid combustion, react with the material, and increase the cutting speed.