What if you could extend the lifespan of critical machine parts by fortifying their surfaces against wear and corrosion? This article delves into spray welding, a cutting-edge technique that does just that. You’ll discover how spray welding works, its advantages over traditional methods, and the types of materials best suited for this process. By the end, you’ll understand how this technology can enhance durability and performance in various industrial applications.

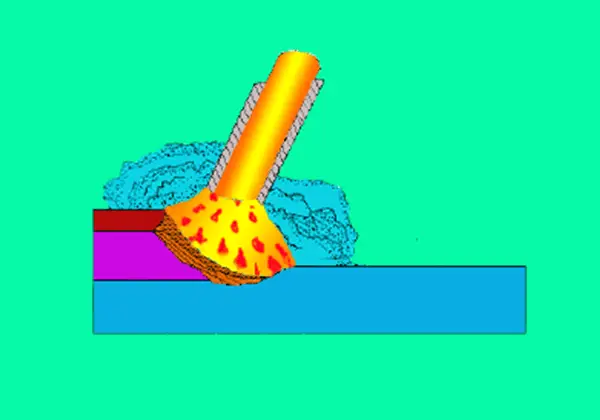

Spray welding involves heating a preheated self-soluble alloy powder coating to a temperature range of 1000-1300℃, melting the particles, floating the slag to the coating surface, and dispersing the boride and silicide in the coating. This process enables a good combination between the particles and the substrate surface.

The final deposit forms a dense metal crystal structure and creates a metallurgical bonding layer of approximately 0.05-0.1mm with the matrix. This bonding layer has a strength of about 400MPa, excellent impact resistance, wear resistance, and corrosion resistance, while also exhibiting a mirror-like appearance.

Compared to spray coating, spray welding coating offers significant advantages. However, due to the high temperature that the matrix reaches during the remelting process, up to 900℃, greater thermal deformation can occur, leading to certain limitations on the application scope of spray welding.

Parts and materials that are suitable for spray welding are generally:

① Vulnerable parts that require high surface hardness and good wear resistance under impact load, such as sander blades, crusher tooth plates, excavator bucket teeth, etc.

② Large vulnerable parts with simple geometries, such as shafts, plungers, sliders, hydraulic cylinders, and chute plates.

③ Materials including low carbon steel, medium carbon steel (less than 0.4% carbon), structural steel containing less than 3% manganese, molybdenum and vanadium, nickel chromium stainless steel, cast iron, and other similar materials.

Self-fluxing alloy powder is composed of nickel, cobalt, and iron as the base materials. Appropriate amounts of boron and silicon elements are added to serve as deoxidizing agents, slag formers, welding flux, and to reduce the alloy melting point. This type of alloy is suitable for remelting the coating with acetylene-oxygen flame.

There are many types of domestic self-fluxing alloy powders available. Nickel-based alloy powders have strong corrosion resistance, oxidation resistance up to 650°C, and exhibit strong wear resistance.

Cobalt-based alloy powder is characterized by excellent red hardness, enabling it to maintain good wear and corrosion resistance up to 700°C.

Iron-based alloy powder has superior abrasive wear resistance compared to the other two types.

The process of spray welding is essentially similar to that of spraying. However, in spray welding, an additional remelting process is carried out during the powder spraying procedure.

Spray welding comprises of two types: one-step spray welding and two-step spray welding.

Before commencing the process, the following points need to be taken into consideration:

① The carburizing or nitriding layer present on the surface of the workpiece must be removed during pretreatment.

② The preheating temperature of the workpiece should be 200-300℃ for ordinary carbon steel and 350-400℃ for heat-resistant austenitic steel. A neutral or weak carbon flame should be used for preheating.

It is important to note that the thickness of the sprayed layer reduces by approximately 25% after remelting. Therefore, this factor must be taken into account while measuring the layer thickness in a hot state after spraying.

One step spray welding.

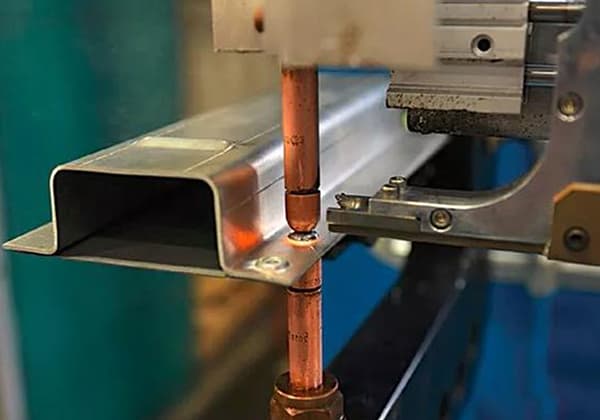

The one-step method involves alternating between spraying and melting one section at a time using the same spray gun.

Medium and small spray welding guns are available for selection.

Before beginning, preheat the workpiece and apply a 0.2mm protective layer, tightly sealing the surface to prevent oxidation.

Start spraying and melting from one end, keeping a distance of 10-30mm.

Heat the protective layer partially in sequence until the melting begins to wet without flowing. Repeat the process, spraying and melting the powder until the predetermined thickness is achieved, and the surface shows a “mirror” reflection. Then continue expanding forward until the entire surface is covered with the spraying and welding layer.

If the thickness is insufficient, repeat the process.

The one-step method is suitable for small parts or small areas requiring spray welding.

Two step spray welding method.

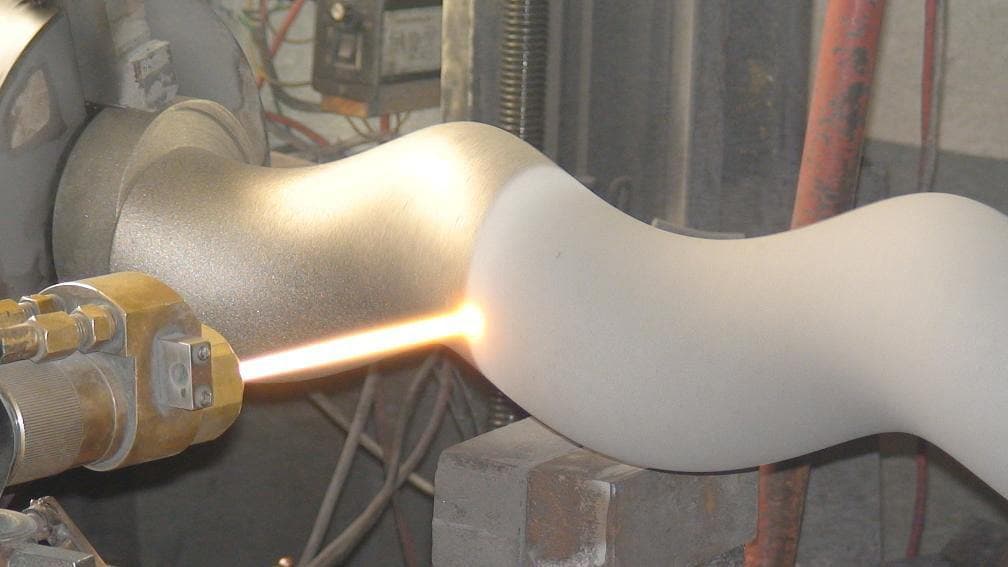

The two-step method involves first applying the spraying layer and then remelting it.

High-power spray guns such as SpH-E spray and welding guns are used to fully melt the alloy powder in the flame and create a plastic deformation deposit layer on the workpiece surface.

Iron-based powder should be sprayed using a weak carbon flame, while neutral or weak carbon flames should be used for nickel-based and cobalt-based powder.

Each layer of powder spraying should be less than 0.2mm thick, and repeated spraying should achieve the desired remelting thickness of generally 0.5-0.6mm.

If a thick spray welding layer is required and one remelting is not enough, it can be sprayed and remelted several times.

Remelting is the key process in the two-step method and should be carried out immediately after spraying.

A high-power soft flame of neutral flame or weak carbonization flame should be used.

The spraying distance should be about 20-30mm, and the angle between the flame and the surface should be 60°-75°.

Starting about 30mm away from the coating, the remelting speed should be properly controlled, and the coating should be heated until a “mirror” reflection of the coating appears before remelting the next part.

During remelting, it is necessary to prevent over-melting (i.e. mirror surface cracking), coating metal flowing, or surface oxidation due to excessive local heating time.

During multi-layer remelting, the previous layer should be cooled to about 700℃, and the surface slag should be removed before secondary spraying.

Remelting should not be done more than three times.

Cooling of the workpiece.

Medium and low carbon steel workpieces, low alloy steel workpieces, and thin welding layer iron castings with simple shapes can be naturally cooled in the air.

However, for iron castings with a thick welding layer and complex shape, alloy steel castings with high contents of manganese, copper, and vanadium, and parts with high hardness, they should be buried in lime pits for slow cooling.

The combination of the spraying layer and spray welding layer with the base metal differs.

When heating nickel-clad aluminum with a spraying flame beam, an exothermic chemical reaction occurs, and rust removal by sandblasting reaches Sa3, RZ>50 μm. The carbon steel surface forms a mechanical bonding coating with a micro-metallurgical bonding bottom layer and a working layer, which also produces an “anchor hook” effect. In contrast, the bonding between the spray welding layer and the substrate is purely a metallurgical bonding coating.

Different spraying materials require the use of self-fusible alloy powder for spray welding, while spraying requires low self-fusibility powder, which is not necessarily self-fusible alloy powder.

Various self-fusible alloy powders can be used for both spray welding and spraying, but the spraying powder does not have self-fusibility. Therefore, it can only be used for spraying and not for the spray welding process.

The workpiece is heated differently during spraying and spray welding, and the preheating temperature before spraying is also different. As a result, the microstructure and properties of the workpiece after spraying are also different.

The density of the coating also differs, as the spray welding layer is dense, while the spray coating has a few pores.

Moreover, the ability to bear load is different. Generally, the spray coating can withstand large-area contact and is mostly used on lubricated working surfaces, mating surfaces, and other working conditions with less stress. However, the spray welding coating can withstand large impact force, extrusion stress, or contact stress.

(1) The surface load on workpieces made of various carbon steel and low alloy steel is significant, especially under impact loads.

For workpieces with bonding strength between coating and substrate of 350-450N/mm2, spray welding hardness HRC150 ≤ 65, coating thickness ranging from 0.3 to several millimeters, and surface roughness of the spray welding layer after grinding reaching Ra0.4-0.1 μm above.

(2) When used in a corrosive medium, the coating must be compact and free of pores.

(3) The original design of the workpiece surface adopts quenching, carburizing, nitriding, hard chromium plating, and other processes, requiring the surface to have high hardness.

(4) The working environment of the workpiece is poor, such as strong abrasive wear, erosion wear, cavitation, etc.

(5) The oxyacetylene flame alloy powder spray welding process is suitable for surface strengthening or repair of various carbon steel and low-alloy steel parts, but some characteristics of the part materials should be noted.

When the linear expansion coefficient of the base material is greatly different from that of the alloy spray welding layer, i.e., less than 12 × 10-6/℃ or greater than 12 × 10-6/℃, this process should be used with caution to avoid cracks.

If the content of elements with high affinity to oxygen in the base metal is more than 3%, such as tungsten and molybdenum, the total content of aluminum, magnesium, cobalt, titanium, molybdenum, and other elements is more than 0.5%, or the sulfur content in steel is more, it will also bring difficulties to spray welding.

This is because these materials generate a dense and stable oxide film under the action of oxygen, blocking the wetting effect of the molten alloy on the base.

During remelting, the liquid alloy will roll down like beads like “sweat beads.”

Therefore, when using the spray welding process, attention should be paid to the adaptability of this process to the sprayed base material.

(6) Metal materials that can be spray welded without special treatment:

① Carbon structural steel with a carbon content ≤ 0.25%.

② Alloy structural steel with total content of Mh, Mo, V, Cr, and Ni <3%.

③ 18-8 Stainless steel, nickel stainless steel, grey cast steel, malleable iron, ductile iron, low-carbon pure iron, red copper.

(7) Metal materials that require slow cooling after spray welding at 250-375 ℃ must be preheated:

① Carbon structural steel with a carbon content >0.4%;

② Manganese, molybdenum, vanadium alloy structural steel with a total nickel content >3%;

③ Alloy structural steel with chromium content ≤ 2%;

(8) Metal materials requiring isothermal annealing after spray welding:

① Martensitic stainless steel with chromium content ≥ 13%;

② Nickel-molybdenum alloy structural steel with carbon content ≥ 0.4%.

After determining the spray welding process, the selection of one-step or two-step spray welding process should be based on the following conditions:

(1) If the workpiece requires local repair, and the spray welding position cannot tolerate a large heat input, use the one-step spray welding process. For instance, repairing local scars on various machine tool guides can be done through this process.

(2) If the workpiece’s surface is complex or irregular, like sprockets, gear tooth surfaces, screw feeders, etc., use the one-step spray welding process.

(3) For large workpieces that are challenging to heat as a whole, such as locomotive and tramcar wheels, the one-step spray welding process should be used.

(4) For general shaft parts that can rotate on the machine tool, use the two-step spray welding process.

(5) The hardness of the coating should be as close as possible to the original design’s surface hardness. For example, if the original design’s surface hardness is HRC≥55, which was achieved through quenching or chemical treatment processes, the “hard coating” powder, such as Ni15, Ni60, Fe65, or Wc composite powder, should be used.

(6) Highly worn non-mating surfaces, such as impellers, mud pump shells, rock loader shovel teeth, spiral feeder surfaces, etc., should be made of high hardness composite powders, such as Ni15, Ni60, Fe65, or Wc.

(7) Workpieces that cannot be processed on lathes and grinders but need to be processed can only be done by hand with files and other tools. For example, repairing local scars on the machine tool guide rail surface requires the use of only low hardness spray welding powders, such as SH, F103, Ni15, etc.

(8) Differences between spray welding and arc surfacing processes:

During the spray welding process, the bonding between the spray welding layer and the matrix is solution diffusion metallurgical bonding, while surfacing uses melting metallurgical bonding.

The matrix is not melted during the spray welding process, but there is a dissolution effect between the spray welding layer and the matrix, resulting in a diffusion mutual solution zone between the two.

Since the matrix is insoluble, the spray welding layer will not be diluted by the base material. Thus, the dilution rate is extremely low, ensuring good performance of the spray welding layer.

In contrast, the overlay welding matrix is melted, and the dilution rate of the overlay welding layer is high. The performance of the welding layer can only be guaranteed if the overlay welding is very thick, making it difficult to guarantee the edges and corners of the part contour. This can lead to common defects such as undercuts and corner collapses. However, spray welding does not have such defects.

(1) Cast iron is an iron-carbon alloy with a carbon content of over 2%. It is widely used in various industries, typically containing 2.5% to 4% carbon, 1% to 3% silicon, and small amounts of manganese, sulfur, phosphorus, etc. Among them, gray cast iron is the most commonly used.

Cast iron has a high carbon content, low strength, and is sensitive to temperature changes. During welding repair, it experiences local heating, large temperature differences, and fast cooling rates. As a result, welding cast iron is challenging.

The poor weldability of cast iron leads to several issues during welding repair:

(2) The welding repair part can easily develop a white microstructure that is hard, brittle, and difficult to machine. Such a structure also tends to crack easily.

(3) The rapid heating and cooling rates during welding repair can cause thermal stress cracks. Additionally, the presence of impurities such as sulfur and phosphorus in the cast iron increases the likelihood of cracking at the weld repair.

(4) Porosity and slag inclusion are also common problems. Due to the high carbon content, more impurities, and rapid cooling rates in the welding repair process, gas and oxides cannot precipitate and float out in time, leading to the formation of porosity or slag inclusion in the weld zone.

Fortunately, one-step spray welding with oxygen-acetylene flame alloy powder can satisfactorily address these problems.

(5) The melting point of the alloy powder used in spray welding is lower than that of the matrix. During remelting, the cast iron matrix does not melt, thereby avoiding the dilution problem of the spray welding layer and the creation of a semi-melted zone. Consequently, correct spray welding does not produce a white microstructure in the weld repair area, making it easier to process.

Furthermore, as the matrix does not melt, it naturally prevents the impurities such as sulfur and phosphorus from melting into the spray welding layer, which helps prevent cracks.

(6) The one-step spray welding process involves less heat input to the substrate and has a lower thermal effect on the substrate, making it more effective in controlling thermal stress cracks. The low heat input is particularly advantageous when repairing parts with high dimensional accuracy.

Additionally, the use of oxygen-acetylene flame heating, which is slower than electric welding cooling, is also helpful in preventing cracks and deformation.

(7) The alloy powder used in spray welding contains strong deoxidizing elements such as boron and silicon. These elements protect the other elements in the powder from oxidative burning and reduce the oxides on the surface of the matrix, thereby preventing the formation of pores and slag inclusion.

(8) The spray welding layer has a compact and flat structure, is well-formed, without undercut, and requires only a small amount of processing. This results in material savings and high efficiency. Spray welded cast iron parts commonly use SH · F103, nickel base alloy powder Ni15, etc. However, iron-based alloy powder has a high melting point, high brittleness, significant impact on the matrix, and poor performance.

(9) During spray welding, the primary purpose of preheating the workpiece is to remove moisture from the workpiece’s surface and generate some thermal expansion. This reduces the temperature difference, thereby minimizing thermal stress and promoting better bonding strength of the spray welding layer.

Preheating temperatures generally range from 250-300℃ for steel, 450-500℃ for austenitic stainless steel, 350-400℃ for nickel-chromium stainless steel, and 250-300℃ for low alloy steel and cast iron. For small workpieces and easily oxidized steel, the preheating temperature is lower.

The thickness of the spray welding layer depends on the workpiece’s thermal expansion and cold contraction characteristics after spraying. The shrinkage after remelting is typically around 25-30%. Therefore, when determining the coating thickness, the machining allowance and workpiece diameter before spraying must be taken into account, along with shrinkage.

The thickness of the spray coating is calculated as follows: Coating thickness before remelting = (thickness of the spray welding layer + machining allowance) ÷ (1-0.3).

Related reading: How to Weld Cast Iron?

(1) Materials with a melting point lower than that of alloys, such as aluminum and its alloys, magnesium and its alloys, brass, and bronze.

(2) The workpiece is a slender shaft or a very thin plate that must not deform.

(3) The original design requirements of the workpiece are very strict, and the metallographic structure cannot change.

(4) Nickel-chromium-molybdenum alloy steel with high hardenability.

(5) Martensitic high-chromium steel with a chromium content greater than 18%.

(Note: High-precision spray welding can be performed on long shafts with an outer diameter exceeding 28mm and a length of less than 8m.)

① There are many parts in vehicles and mechanical equipment made of cast iron, and various issues are inevitable during manufacturing or use. The oxygen acetylene flame spray welding process is not only an effective way to strengthen cast iron, but also an ideal means to repair various defects and damages, such as sand holes, air holes, wear, and other damages in castings.

② Spray welding is mostly used to repair local defects of iron castings, which vary in size and depth. It is suitable for one-step spray welding. Small power spray guns should be used as far as possible to reduce the heat input to the substrate, depending on the parts of the workpiece and welding repair needed. Generally, QH-1/h, QH-2/h, QH-4/h, etc., are selected.

③ During spray welding, nickel base alloy powder (Ni-B-Si series) should be preferred because of the poor weldability of cast iron parts. The melting point of nickel base alloy powder is generally 950~1050 ℃, and the matrix will not melt during remelting. At the same time, the nickel base powder spray welding layer with low carbon content has low hardness and good plasticity. Relaxation of spray welding stress is helpful to prevent cracks, which is extremely important for unskilled operators.

④ When selecting spray welding specifications, factors such as cast iron material, size of defect parts, and working condition requirements should be considered. It is important to ensure necessary flame energy while minimizing heat input to the substrate. Appropriate oxygen and acetylene gas pressure limits should be followed, and the spraying and melting distance should be properly adjusted during powder spraying and remelting to control heat input.

⑤ Local small defects, such as air holes and sand holes, can be repaired by welding without preheating before spray welding. The heating area around the spray welding layer should be minimized to make the high-temperature area as small as possible.

⑥ For the repair of local small and deep defects, continuous spray welding is suitable. This method has a high powder deposition rate, rapid thickness growth, and high efficiency, but requires skilled operation technology to coordinate the powder feeding amount with spraying and melting speed to achieve uniform spraying and penetration.

⑦ For large and deep defects, intermittent spray welding can be used to prevent an increase in thermal stress due to excessive heating of the substrate. Electric welding and spray welding can also be used, and welding rods can be used to fill the bottom and upper parts for spray welding. If the wall thickness of the casting is large, pre-spray wire planting can be used to increase bonding strength, prevent the spray welding layer from peeling off from the base metal, and eliminate some of the thermal stress of spray welding.

⑧ Large complex castings for spray welding often experience high thermal stress, so measures should be taken to reduce stress accumulation during spray welding, such as using heating stress reduction methods and the subsection symmetry method. Preheating before welding and slow cooling after welding can also achieve good results.

⑨ It is important to control the remelting temperature during spray welding. If the temperature is too high, alloy elements can burn, the matrix can overheat, and even melt, resulting in the carbon in the cast iron entering the spray welding layer. This increases the carbon content, hardness, and reduces plasticity, and can cause greater thermal stress leading to crack formation. However, if the remelting temperature is too low, it can lead to ash inclusion or impenetrability and affect bonding strength. Operators should pay attention to the coating surface state during remelting and remove the remelting gun immediately once “mirror reflection” is displayed indicating that the powder has melted, and the slag has floated. The remelted parts should not be reheated.