Imagine a world where cutting through the hardest materials is as easy as slicing butter. This is the promise of non-traditional machining. In this article, we explore how advanced techniques like EDM and laser machining are revolutionizing manufacturing. Get ready to uncover the secrets behind these powerful methods and their incredible applications!

First, let’s look at the definition of non-traditional machining.

Non-traditional machining, also referred to as “non-conventional machining” or “modern machining method,” generally involves using energy from electricity, heat, light, electrochemistry, chemistry, sound, or special mechanics to remove or add materials.

This results in the removal, deformation, change in properties, or plating of materials.

Traditional mechanical machining has a long history and has played a significant role in human production and material civilization.

Currently, most of our products are manufactured and assembled using traditional methods, such as household appliances (e.g., refrigerators, washing machines, air conditioners), transportation vehicles (e.g., cars, trains, planes), and weapons and equipment (e.g., guns, cannons, tanks, rockets).

Traditional mechanical machining involves using mechanical energy and cutting force to remove excess metal, resulting in a part with a specific geometric shape, size, and surface roughness. The tool material must be harder than the workpiece material.

However, with the advancement of science and technology, especially since the 1950s, and the need for high-precision, high-speed, high-temperature, high-pressure, and miniaturized products, particularly in the defense industry, the difficulty in machining materials has increased, with more complex shapes and higher dimensional accuracy and surface roughness requirements.

To address these challenges, new requirements have arisen for the mechanical manufacturing industry, including the ability to machine difficult-to-cut materials such as hard alloys, titanium alloys, heat-resistant steels, stainless steels, quenching steels, diamond, precious jade, quartz, germanium, silicon, and non-metallic materials.

Additionally, new machining methods are required to address complex surface machining, such as the stereo forming surface of steam turbine blades, integral turbines, engine casings, and forging dies, as well as special sections on punching and cold drawing dies, internal rifling, spray nozzles, grids, holes, and narrow slits on spinning nozzles.

To meet these demands, researchers have been exploring and developing non-traditional machining (NTM), also known as non-conventional machining (NCM), which uses physical energy (electricity, magnetism, sound, light, and heat), chemical energy, and even mechanical energy to directly affect the machining area and remove, deform, or change the material.

Traditional machining methods are no longer adequate to meet these technical challenges, making non-traditional machining a necessary solution.

Non-Traditional Machining (NTM) has the following distinctive features:

Because of its above mentioned characteristics, non-traditional machining technology is capable of processing materials, whether metal or non-metal, with any level of hardness, strength, toughness, and brittleness, and specializes in machining complex, micro-surfaces and low-stiffness parts.

At the same time, some methods can be used for superfinishing, mirror finishing and nanometer (atomic) machining.

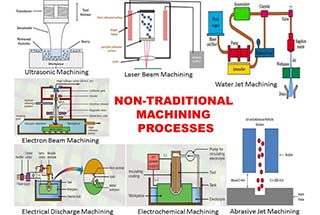

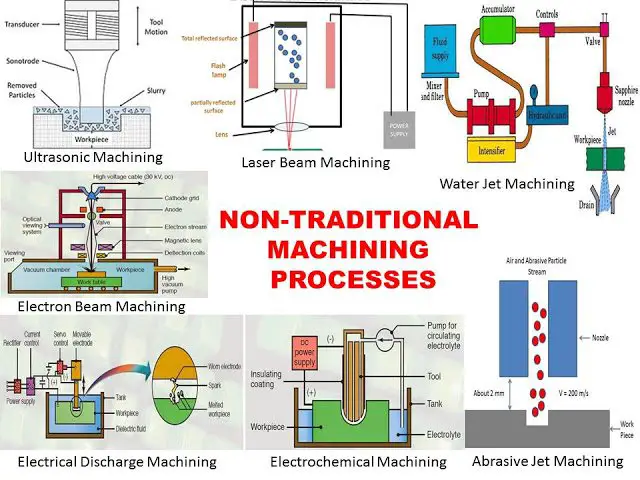

The classification of non-traditional machining has not yet been specified. Generally, it can be divided into different forms based on the energy source, function form, and machining principle, as shown in the following table.

| Machining method | Major energy form | Functional form | |

| Electrical discharge machining | EDM forming machining | Electricity, Thermal energy | Melting, gasification |

| EDM cutting machining | Electricity, Thermal energy | Melting, gasification | |

| Electrochemical machining | Electrochemical machining | Electrochemical energy | Ion transfer |

| Electroforming machining | Electrochemical energy | Ion transfer | |

| Plating machining | Electrochemical energy | Ion transfer | |

| High energy beam machining | Laser beam machining | Light, Thermal energy | Melting, gasification |

| Electron beam machining | Electricity, Thermal energy | Melting, gasification | |

| Ion beam machining | Electricity, Mechanical energy | Abscission | |

| Plasma arc machining | Electricity, Thermal energy | Melting, gasification | |

| Material cutting and erosion machining | Ultrasonic machining | Acoustic, mechanical energy | Abscission |

| Abrasive flow machining | Mechanical energy | Abscission | |

| Chemical machining | Chemical milling machining | Chemical energy | Corrosion |

| Photographic plate making | Chemical energy | Corrosion | |

| Light energy | |||

| Lithography process | Light, Chemical energy | Photochemical, corrosion | |

| Photoelectroforming plating | Light, Chemical energy | Photochemical, corrosion | |

| Etching machining | Chemical energy | corrosion | |

| Bonding | Chemical energy | Chemical bonds | |

| Explosion machining | Chemical energy, Mechanical energy | explosion | |

| Forming machining | Powder metallurgy | Thermal energy | Thermoforming |

| Mechanical energy | |||

| Superplastic forming | Mechanical energy | Superplastic | |

| Rapid prototyping | Thermal energy | Hot melt forming | |

| Mechanical energy | |||

| Composite machining | Electrochemical arc machining | Electrochemical energy | Melting and gasification corrosion |

| Electro-discharge mechanical grinding | Electricity, Thermal energy | Ion transfer, melting, cutting | |

| Electrochemical etching | Electrochemical energy, Thermal energy | Melting, Gasification corrosion | |

| Ultrasonic EDM | Sound, heat, electricity | Melting, Abscission | |

| Complex electrolytic machining | Electrochemical energy, mechanical energy | Abscission | |

| Cutting Base Combined Machining | Mechanical, acoustic and magnetic energy | Cutting | |

Basic principle:

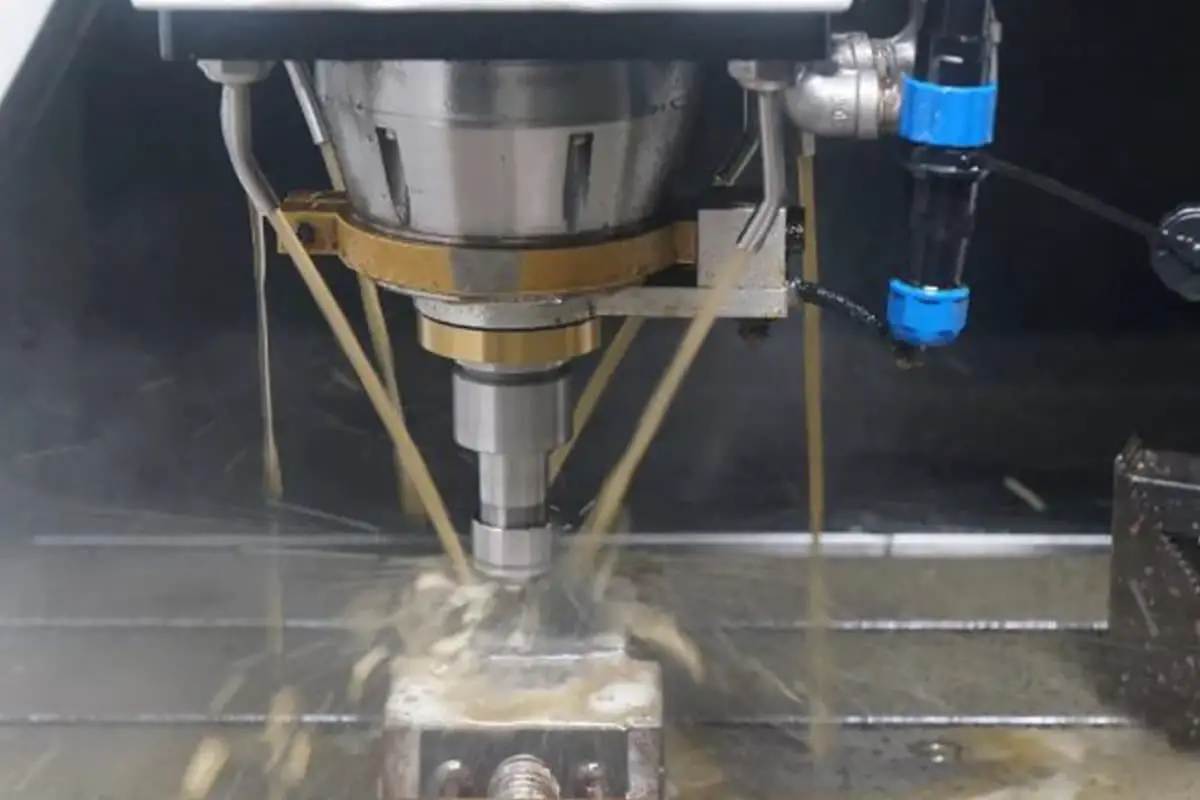

EDM, or Electro-Discharge Machining, is a type of non-traditional machining method that involves etching conductive materials through electric erosion caused by pulse discharge between two poles immersed in a working liquid. This process is also known as Discharge Machining or Electroerosion Machining. The basic equipment for this method is an Electro-Discharge Machine Tool.

Main Features of EDM:

Range of Application:

Basic Principle:

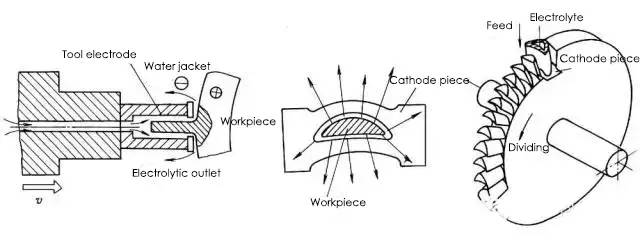

The principle of electrochemical dissolution is utilized in electrolytic machining, with the aid of a mold as the cathode. The workpiece is machined to a specific shape and size.

Range of Application:

Electrolytic machining is ideal for materials that are challenging to machine and for parts with complex shapes or thin walls.

This method has been widely used for various applications, such as gun barrel rifling, blades, integral impellers, molds, profiled holes and parts, chamfering, and deburring.

In many machining operations, electrolytic machining technology has gained a significant or even indispensable role.

Advantages:

Limitations:

Basic principles:

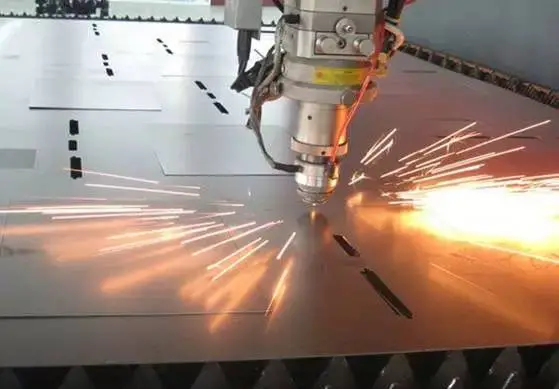

Laser machining is a process that uses high-energy light beams, focused by a lens, to melt or vaporize materials and remove them in a short amount of time to achieve machining.

Advantages:

Laser machining technology has advantages such as minimal material waste, cost-effectiveness in large-scale production, and versatility in machining objects. In Europe, laser technology is widely used for welding special materials such as high-grade automobile bodies, aircraft wings, and spacecraft fuselages.

Range of application:

As the most commonly used application, the technologies of laser machining mainly include laser welding, laser cutting, surface modification, laser marking, laser drilling, micro-machining and photochemical deposition, stereolithography, laser etching and so on.

Basic principles:

Electron beam machining (EBM) is the machining of materials by using the thermal or ionization effects of high energy convergent electron beam.

Main features:

High energy density, strong penetration, a wide range of one-time melting depth, large weld width ratio, fast welding speed, small thermal impact zone, small working deformation.

Range of Application:

The electron beam machining has a wide range of machinable materials and can machining on very small areas.

It achieves machining accuracy at the nanometer level, capable of molecular or atomic machining.

It has high productivity, but the cost of the machining equipment is high.

The machining process produces minimal pollution.

It is suitable for machining micro-holes and narrow slits and can also be used for welding and fine lithography.

The vacuum electron beam welding bridge shell technology is the primary application of electron beam machining in the automobile manufacturing industry.

Basic principles:

The ion beam machining is realized by accelerating and focusing the ion stream generated by the ion source to the surface of the workpiece in a vacuum state.

Main features:

Due to the precise control of ion flow density and ion energy, ultra-precision machining at the nanometer, molecular, and atomic levels can be achieved. Ion beam machining results in minimal pollution, stress, and deformation, and is adaptable to the processed materials, but comes at a high cost.

Range of application:

Ion Beam Machining can be divided into two types: etching and coating.

Etching Machining:

Ion etching is used in machining the air bearing of gyroscopes and grooves on dynamic pressure motors, with high resolution, high precision, and good repetition consistency.

Another application of ion beam etching is the etching of high-precision graphics such as integrated circuits, optoelectronic devices, and optical integrated devices.

Ion beam etching is also used for thinning materials to prepare specimens for penetrating electron microscopy.

Coating Machining:

Ion beam coating machining has two forms: sputtering deposition and ion plating.

The ionic coating can be applied to a wide range of materials. Metal or non-metal films can be plated on metal or non-metal surfaces, and various alloys, compounds, or synthetic materials, semiconductor materials, and high-melting-point materials can also be coated.

Ion beam coating technology is used for coating lubricating films, heat-resistant films, wear-resistant films, decorative films, and electrical films.

Basic principles:

Plasma arc machining is a non-traditional machining method to cut, weld and sprays metal or non-metal by the heat energy of the plasma arc.

Main features:

Range of application:

It is widely used in industrial production, especially for the welding of copper and copper alloy, titanium and titanium alloy, alloy steel, stainless steel, molybdenum used in military industry and cutting-edge industrial technology such as aerospace, such as titanium alloy missile shell, some of the aircraft thin-walled containers.

Basic principles:

Ultrasonic machining makes the surface of the workpiece gradually break by the use of ultrasonic frequency as the tool for small-amplitude vibration and punch on the processed surface by free-abrasive in the liquid between it and the workpiece.

Ultrasonic machining is often used for piercing, cutting, welding, nesting and polishing.

Main features:

Can machining any material, especially suitable for machining of various hard, brittle non-conductive material, with high precision, good surface quality, but in low productivity.

Range of application:

Ultrasonic machining is mainly used for perforation (including round holes, shaped holes and curved holes, etc.), cutting, slotting, nesting, carving of various hard and brittle materials, such as glass, quartz, ceramics, silicon, germanium, ferrite, gemstone and jade, deburring small parts in batches, polishing of mold surface and grinding wheel dressing.

Basic principles:

Chemical machining makes use of acid, alkali or salt solution to corrode or dissolve the material of the parts to obtain the desired shape, size or surface of the workpiece.

Main features:

Range of application:

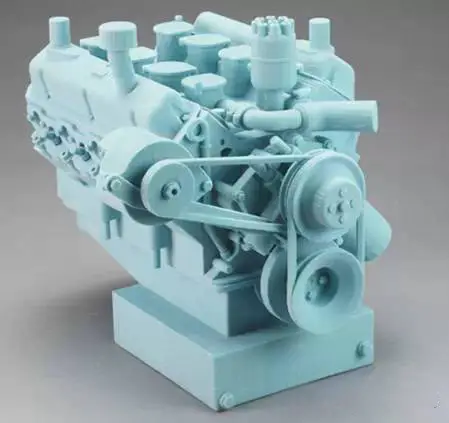

RP Technology is an integration and development of modern CAD/CAM technology, laser technology, computer numerical control technology, precision servo drive technology, and new material technology. Different rapid prototyping systems have distinct forming principles and system characteristics due to varying forming materials, but the fundamental principle remains the same, which is ‘manufacturing by layers, building upon each layer.’

It is similar to a mathematical integration process, and visually, the rapid prototyping system resembles a “3D printer.

Basic principles:

The integration and development of RP technology, based on modern CAD/CAM technology, laser technology, computer numerical control technology, precision servo drive technology, and new material technology, allows for direct receipt of product design (CAD) data and the rapid manufacture of new product samples, molds, or models without the need for molds, cutters, or fixtures.

As a result, the widespread use and application of RP technology significantly shortens the development cycle of new products, reduces development costs, and improves development quality.

The transition from the traditional “elimination method” to today’s “growth method,” and from mold manufacturing to mold-free manufacturing, represents the revolutionary impact of RP technology on the manufacturing industry.

Main features:

RP technology converts complex three-dimensional machining into a series of layered machining, significantly reducing the difficulty of machining. It possesses the following traits:

The above characteristics indicate that RP technology is ideal for the development of new products, the rapid manufacture of single and small-batch parts with complex shapes, the design and production of molds and models, and the production of materials that are challenging to machine.

Additionally, it is well suited for the inspection of shape design, assembly, and rapid reverse engineering.

Range of application:

Rapid prototyping technology can be applied in the fields of aviation, aerospace, automobile, communications, medical treatment, electronics, household appliances, toys, military equipment, industrial modeling (sculpture), building model, machinery industry, etc.

In this article, we have listed nine types of non-traditional machining techniques, which could serve as a handy guide for those who want to learn about the non-traditional machining process, its advantages, classifications, and more.