During the working process, the positions of the top dead center, speed change point, and bottom dead center of the CNC press brake must be adjusted according to the process requirements for bending the workpiece. The working pressure of the hydraulic system should also be adjusted according to the actual bending force.

Stroke adjustment

Top dead center adjustment

The top dead center position can be adjusted by programming the “opening” item of the controller to change the upper and lower positions. Refer to the “CNC system operation manual” for details.

Variable speed point adjustment

The variable speed point is the position of the ram when it switches from no-load speed to working speed. The position of the shift point can be adjusted by programming the “shift point” item of the controller.

Bottom dead center adjustment

After the ram completes the working stroke, the lower dead center position can be adjusted by programming the “Y-axis value” item of the controller.

Working pressure adjustment of hydraulic system

The pressure required for bending can be calculated using the table lookup method or formula method, and the table lookup method is preferred.

Calculation of pressure by formula method

The required bending pressure can be calculated from the following bending formula:

Where:

- F – load (KN)

- S – plate thickness (mm)

- L – bending length (m)

- V – opening distance (m)

- σ b – tensile strength (N/mm²)

The new international standard unit of force is Newton.

- 1kgf ≈ 10N

- 1tf ≈ 10000N=10kN

- 1MPa ≈ 10bar

For example:

Plate material: 16Mn, σ b = 530N/mm², plate thickness: S = 15mm, plate length: L = 10000mm = 10m

Lower die opening distance: V = 8 × S=8 × 15 = 120mm

Calculated bending force F1 = 1.42×10000×530×15²/(1000×120) ≈ 14000 (KN)

Considering the influence of various factors, 10% reserve shall be added to calculate the bending force.

Therefore, F2=1.1 × F1 = 1.1 × 14000=15400(kN)

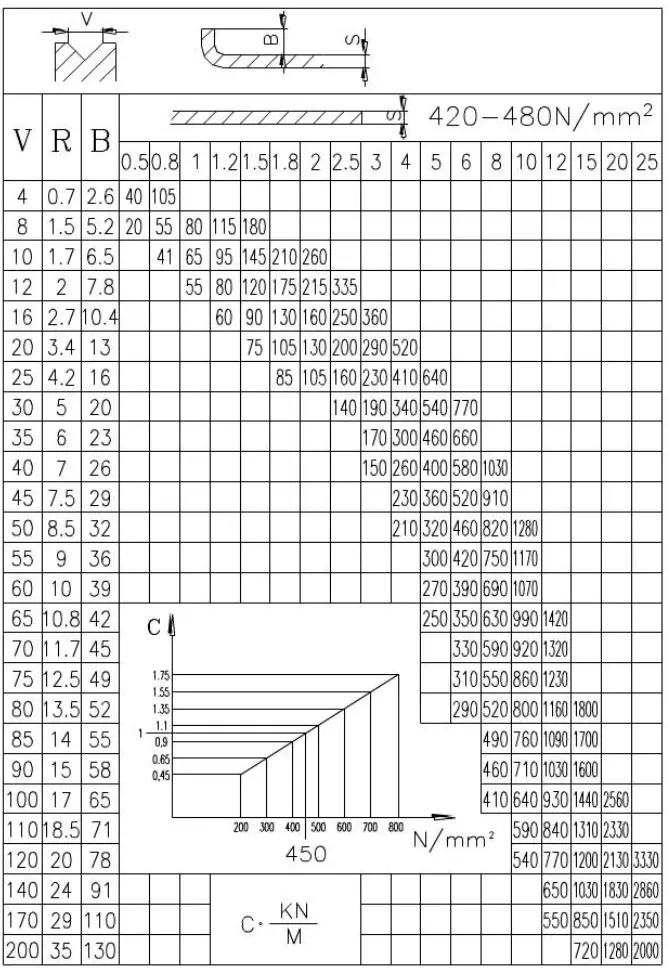

Calculation of pressure by table lookup method

The bending pressure table is shown in Figure below.

The value of bending force in the table is given when σ b = 450N/mm², and its unit is KN/m.

In the table,

- S – plate thickness (mm)

- V – opening width of lower die (mm, 8 × plate thickness)

You can use the bending pressure table to determine the required bending pressure.

For example:

It can be seen from the table that at the intersection of plate thickness S = 15mm and opening distance V = 120mm, the bending force per meter is F3 = 1200kN/m

Since σ b = 530N/mm², check table C ≈ 1.18. (530/450≈1.18)

Calculate bending force: F1=F3 × L × C=1200 × 10 × 1.18 ≈ 14000 (kN)

The required bending force shall be calculated by adding 10% reserve.

Therefore, the required bending force: F2=1.1 × F1=1.1 × 14000=15400 (kN)

Working pressure adjustment

If the calculated bending force F2 of a bending length is less than the machine output force P in the above table, the working pressure of the hydraulic system should be reduced in order to reduce the oil temperature and improve the service life of the hydraulic components.

The working pressure Q of the hydraulic system can be calculated by the following formula:

Q=28 × F2/P(MPa)

The working pressure of the hydraulic system can be adjusted by the machine tool controller.

During the adjustment, check the corresponding P value in the bending pressure table according to the actual bending force, and input it into the computer.

Convex amount of worktable

The workbench and ram are supported at two points along the entire length.

Under the action of loading force P, deformation will occur, and the amount of deformation is represented by f (refer to the figure below).

In order to solve this problem, the machine adopts a movable “convex” on the worktable to compensate for the deformation of the worktable and ram and improve the accuracy of the angle and straightness of the workpiece.

The adjustable convex amount of the worktable ranges from 0 to 2.0mm.

During operation, determine the convex value according to the actual bending load force (or the angle difference between the two ends of the workpiece and the middle), and then input it into the controller for operation.

There is a small hole and a set of numbers at the end of the convex adjustment motor, which serve as the reference positions of the measurement hole and the convex zero point, respectively. These provide convenience for users to determine the convex zero point.