Imagine welding with a precision tool that never even touches the metal. Remote Laser Welding (RLW) harnesses the power of fiber lasers to revolutionize the welding process, offering unmatched speed, flexibility, and efficiency. This article explores how RLW systems, with their high-quality beams and advanced scanning technology, are transforming industries from automotive to aerospace. Readers will gain insights into the workings, benefits, and challenges of RLW, along with practical applications and future prospects of this cutting-edge technology.

Remote Laser Welding (RLW) technology, a non-contact robotic laser welding process, has seen significant advancements in recent years. This has led to improved production efficiency and greater processing flexibility in the laser welding process.

The concept of RLW was first introduced in 1996 by John Macken.

One of the key features of RLW is its perfect combination of a high-power, high-beam quality laser source with a long focal length (up to 1600 mm) and a galvanometer scanning device.

Compared to traditional laser welding, RLW offers faster speed, shorter cycles, and greater flexibility.

RLW technology research has been applied to various types of lasers for a long time. The high-power fiber laser with a 1080nm wavelength is capable of transmitting the laser beam through fiber and improving the accuracy of focusing and processing flexibility.

On the other hand, the CO2 laser with a long wavelength of 10.6μm cannot transmit the beam through optical fiber.

Due to its ideal wavelength and excellent beam quality, the high-power fiber laser is the preferred choice for RLW applications, outperforming traditional CO2 lasers and Nd: YAG lasers.

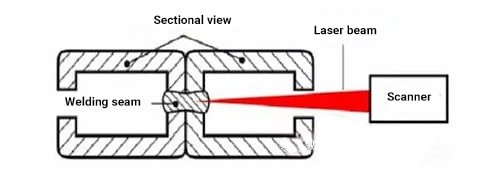

The working principle of RLW is to reflect and direct the laser beam through galvanometer scanning, allowing for high-speed transmission to the surface of the workpiece.

2D scanning is the most commonly used in the RLW field. It consists of a galvanometer system with two light scanning mirrors that can be electrically rotated. The system can handle an output power of 5 kW, making it more cost-effective than 3D scanning.

However, RLW also faces several challenges, such as the need for pre-processing, welding quality and stability requirements, the provision of shielding gas, and the proper clamping and positioning of the plated sheet.

Compared to traditional laser welding, RLW requires a larger number of process parameters, which can be broadly categorized into three groups: beam quality, processing parameters, and material properties.

The idea behind Remote Laser Welding (RLW) is not entirely new. Its main principle involves reflecting and positioning the focused laser beam at a specific distance above the workpiece using a scanner. The typical focal length for RLW ranges between 1000 and 1600 mm.

In 1996, John Macken carried out the first RLW experiment using a laser with a focal length of 1600 mm. This experiment was a milestone in the development of the RLW process, as it achieved small hole pattern welding.

The scanner helps to correctly project the laser beam onto a large workpiece, with an area of 1 m x 1 m or even larger, and the welding speed can reach 30 m/min.

There are two general working modes for the RLW process: the RLW system with an integrated scanner and the RLW system based on a robot.

The RLW system with an integrated scanner uses a scanning unit, typically a 2D scanner, to focus and position the laser beam (refer to Figure 1(a)).

The robot-based RLW system utilizes a long-focus laser optical mirror and a six-axis robot for operation. The robot is responsible for positioning the laser beam on the surface of the workpiece (refer to Figure 1(b)).

Figure 1. RLW system with integrated scanner (a) and robot-based RLW system (b)

Compared to the robot-based RLW system, the RLW system with an integrated scanner has a wider range of applications, with a shorter processing cycle and higher accuracy. However, this system has much stricter requirements for the quality of the laser beam.

Table 1 provides a comparison of the performance of the RLW system with an integrated scanner, the robot-based RLW system, and traditional laser welding.

Table 1. Comparison of parameters between remote welding process and traditional laser welding process

| Typical performance parameters | Traditional laser welding process | RLW system with integrated scanner | Robot-based RLW system |

|---|---|---|---|

| Cycle | 1 | 3 | 2 |

| Precision | 3 | 3 | 2 |

| Practicality | 1 | 3 | 3 |

| Flexibility | 2 | 3 | 3 |

| Programmability | 2 | 1 | 2 |

| Investment | 3 | 2 | 3 |

| Maintainance | 3 | 2 | 3 |

1=very bad/very low; 2=not bad; 3=good

For successful remote welding results, the following three conditions must be met:

2.2.1. Scanner

The scanner ensures that the laser beam is correctly guided along the desired welding path on the surface of the workpiece and positioned rapidly.

The highly flexible and lightweight scanning head allows the beam to move quickly between welding points, reducing the time required for positioning compared to traditional laser welding processes.

Figure 2 illustrates the typical components of a scan head. The scanning unit is composed mainly of a set of galvanometers and a lens.

In remote welding, the laser beam first passes through the lens. The lens can be adjusted along the optical axis to change the focal position. The laser beam is then reflected and guided successively by the X and Y galvanometers, finally reaching the established weld seam and accurately focusing on the surface of the workpiece.

Figure 3 shows a typical 2D scanner system, which includes a seam tracking sensor, a linear projection device, and a highly sensitive 2D scanning unit.

Figure 2. Typical components that make up the scan head

Figure 3. The main components of the 2D scanner system

2.2.2. High power fiber laser

In recent years, high-power fiber lasers have undergone rapid development and have demonstrated exceptional characteristics in material processing applications.

High-power fiber lasers with high-quality beams can provide ultra-high peak power density, reaching several MW/mm2, which is crucial for long-distance, high-speed remote laser welding.

Research data indicates that high-power fiber lasers have several advantages, such as:

As shown in Figure 4, an RLW unit equipped with a high-power fiber laser is mounted by an industrial robot and has a welding head fixture.

Research indicates that remote fiber laser welding can further increase the welding speed, reduce the loss of welding wire and torch, lower the requirements for tool and component tightening, and decrease the ongoing maintenance costs associated with traditional welding processes.

Figure 4. RLW unit with 5 kW fiber laser

Compared to the traditional laser welding process, the RLW system with an integrated scanner has several advantages, such as:

2.3.1. Efficient production

The RLW system with an integrated scanner is more efficient due to its fast welding speed and short processing cycle.

Under normal conditions, the welding speed can be increased from 6 m/min to 30 m/min, depending on the output power of the configured laser.

Eliminating non-working time for the scanner can further shorten the processing cycle by 80%.

The uninterrupted movement and rapid positioning of the scanning head allow the RLW system to move between welds in just 50 ms, while robot positioning typically takes 2-3 seconds.

As a result, the processing cycle for the RLW system with an integrated scanner is 6-10 times faster than resistance spot welding or arc welding.

2.3.2. Highly flexible

The long-distance operation between the scanning head and the workpiece in the RLW system provides great flexibility during welding, which is not possible with traditional laser welding equipment.

As shown in Figure 5, the weld can only be completed with long-distance operation.

Another benefit of long-distance operation is that it prevents metal vapor or spatter from affecting optical components.

Furthermore, long-distance operations have lower requirements for fixtures, effectively reducing equipment costs in applications involving heavy or large products.

Figure 5. RLW is used for welding workpieces with poor accessibility

2.3.3. Cost advantage

RLW has already demonstrated its cost-effectiveness in the production of BIW. Numerous research results show that the RLW system can reduce production costs in various ways, such as:

However, RLW also has its disadvantages, such as the need for shielding gas, high-quality beams, fixtures, and weld tracking.

The biggest challenge for RLW is providing shielding gas to the workpiece. The auxiliary gas must cover the entire processing area, rather than moving synchronously with the weld. This requires a large number of nozzles to inject protective gas at a high flow rate simultaneously to prevent oxidation and avoid contamination. As a result, a large amount of shielding gas is needed, which increases the cost of the process.

At present, resistance laser welding (RLW) is primarily utilized for mass production of flat panel assemblies, which often involves a substantial amount of welding.

The automobile manufacturing industry is a key application area for RLW.

To date, approximately 70 RLW systems have been implemented in various production processes, including the manufacture of car seats (such as seats, frames, rails, and panels), body-in-white components (such as luggage compartments, rear panels, doors/suspension parts, side walls, and heat exchangers), and interior structures (such as reinforcing ribs and rear window shelves/top guards).

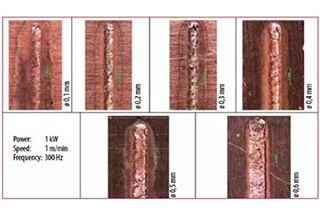

Researchers have conducted numerous tests and studies on various process parameters, such as welding speed, focus position, beam inclination, shielding gas, joint design, and base metal properties, in order to improve the beam characteristics of RLW. These characteristics include laser power, beam quality, wavelength, spot diameter, focal length, mode, and polarization.

The researchers have studied RLW equipped with fiber lasers using four different types of steel as base materials, including mild steel, galvanized steel, alloy galvanized steel, and stainless steel.

The main process parameters are presented in Table 2 below.

Table 2. List of process parameters of RLW with fiber laser

| Base Materials | Output power | Focal length | Spot dia. | Welding speed | Focus position | Time |

|---|---|---|---|---|---|---|

| (Thickness mm) | KW | mm | μm | m/min | mm | (ref.) |

| Soft steel S355 (1.5mm) | (mm) 8 | 470 | 640 | 2-14 | 0 | 2008(6) |

| Soft steel S235 | (mm) 8 | 1053 | 300-800 | 2-22 | -80-80 | 2007(15) |

| Galvanized steel JAC270EN (1.5mm) | 4 | 1250 | 360 | 5 | 0 | 2009(35) |

| Alloy galvanized steel GA60 (1mm) | 4 | 1500 | / | 4 | 0 | 2009(8) |

| Stainless steel 1.4301 (20mm) | (SM) 3 | 500 | 109 | 4-10 | 0 | 2009(36) |

Additionally, the researchers have also extensively examined various process parameters, including output power, welding speed, shielding gas supply, beam inclination, and focus position.

In the laser processing process, increasing the laser power results in a corresponding increase in welding speed.

According to the data, when welding mild steel with remote laser welding, if the output power of the fiber laser is increased from 4 kW to 8 kW while the spot diameter remains constant, the welding speed will significantly increase. However, with the increase in laser power, there may be issues such as spattering and sagging welds that can negatively impact the welding quality.

Figure 7 shows the relationship between laser power and both welding speed and penetration depth when welding mild steel S355 using remote laser welding.

As the chart indicates, an increase in laser power leads to an increase in both welding speed and penetration depth.

Figure 7. The influence of output power on RLW (with exhaust device, no protective gas, spot diameter 640 & mm, focal length 470 mm, S335 mild steel)

Welding speed is a critical factor in the resistance laser welding (RLW) process.

The welding speed is primarily determined by the power density, required penetration depth, laser mode, focus position, and number of scans.

The welding speed influences the appearance of the weld pool, the shape of the weld joint, and the penetration depth.

Figure 8 illustrates the relationship between welding speed and welding depth when remote laser welding is performed on stainless steel 1.4301 with different laser powers.

As shown in Figure 8, higher welding speeds result in shallower welding depths, and greater laser power results in deeper welding depths.

Figure 8. The influence of welding speed on RLW welding depth

(Stainless steel 1.4301, 3 kinds of output power, focal length 500mm)

Using shielding gas during remote laser welding offers several benefits, including preventing oxidation of the welding area, reducing metal vapor, clearing metal particles from the beam path, stabilizing the welding process, and preventing the formation of plasma.

When performing RLW on steel, the most commonly used protective gases are argon, helium, nitrogen, and compressed air.

The typical flow rate of RLW shielding gas is around 15-20 liters per minute, which varies based on the length of the welding area.

Figure 9. The influence of shielding gas on RLW welding depth and welding speed

(Steel plate, 8 kW output power)

When conducting high-power remote fiber laser welding, the impact of shielding gas on welding depth and speed can be seen in Figure 8.

Regardless of whether shielding gas is used, as the welding speed increases, the penetration depth will continue to decrease.

However, at welding speeds lower than 5 meters per minute, the use of shielding gas becomes a significant factor affecting the welding process. This is likely because the large amount of metal vapor generated in the small holes obstructs the welding process.

When the welding speed increased to 14 meters per minute, the effect of shielding gas on the RLW welding depth started to become more pronounced.

Due to the long working distance, the acceptable range of inclination angles for resistance laser welding (RLW) is extensive.

The size and shape of the spot produced by the laser beam on the workpiece surface will vary with changes in the inclination angle.

As the power density and absorbance change, the beam angle will impact the penetration depth and interface width.

When the inclination angle exceeds 60°, it significantly affects the penetration depth. In contrast, little difference in the welding process is observed when the inclination angle is between 20° and 30°.

According to the data, when the inclination angle is between 0° and 20°, it has no impact on the welding quality.

The focus position influences the penetration depth, shape of the weld joint, and the quality of the cut.

The focal position of the laser beam varies with the thickness of the base material.

To achieve the best penetration effect, the focal position is typically placed about 1 millimeter above the surface of the workpiece.

Figure 10 illustrates the relationship between focal position and penetration depth when a disk laser is used for remote laser welding of steel.

As shown in Figure 10, when the focal position is at 0 millimeters on the surface of the workpiece, the penetration depth is the deepest.

As the distance of the focused laser beam increases, the penetration depth decreases.

Figure 10. The effect of focus position on RLW welding depth and width

The purpose of this article is to investigate the remote laser welding process using fiber lasers.

The remote fiber laser welding process holds great potential for a wide range of applications.

Due to its high productivity, excellent flexibility, and low overall cost, the process has been adopted in the automobile manufacturing industry.

For the remote fiber laser welding unit, the scanner is the most critical component.

However, to achieve good welding results, users must also consider a range of process parameters, such as beam quality, laser power, welding speed, shielding gas supply, focus position, and others, during remote laser welding.