How can production lines quickly adapt to diverse and small-batch orders while maintaining cost efficiency? This article explores the innovative use of turret punching in manufacturing. By integrating turret punching with traditional methods like laser cutting, manufacturers can streamline production, reduce costs, and enhance flexibility. Readers will learn how this hybrid approach optimizes efficiency for parts with complex designs, making it an essential strategy for modern production environments.

At present, with more and more orders and customized products in the market, there are more and more cabs and assemblies with multiple varieties and small batches in the main engine factory.

For multi-variety and small-batch purchasing plans, how can the production workshop quickly complete the trial production of products and deliver them to the main engine factory?

The application of sheet metal technology in the production workshop is particularly important, especially the processing method of turret punching, which shortens the product delivery cycle and reduces the processing cost and can meet the needs of the main engine factory in time.

In the tractor cab and assembly parts, there are often parts with regular contours and many holes in the inner cavity contour.

At first, when planning the sheet metal process, it was considered to use the plane laser cutting process for production and processing.

There was no problem in using the plane laser cutting process. However, with the increasing load of the plane laser cutting machine, the plane laser cutting would become a bottleneck process.

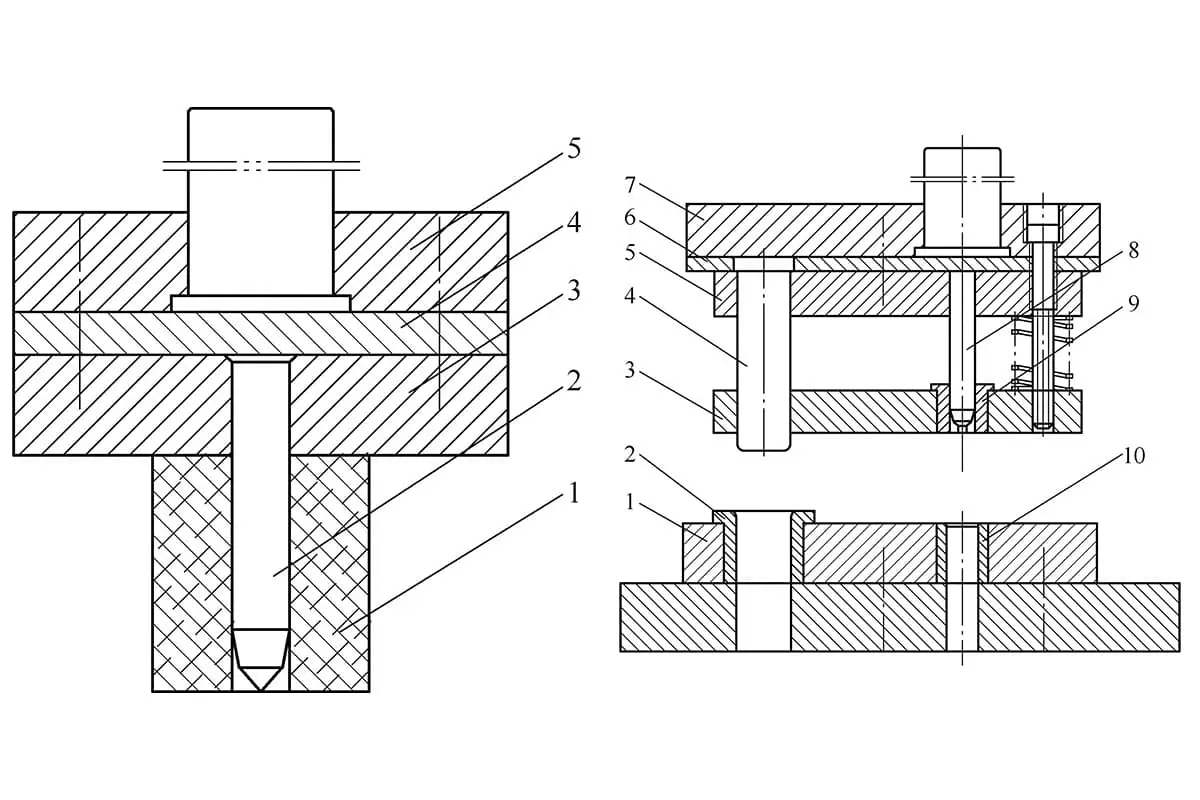

Considering that our turret punching equipment (Figure 1) still has surplus capacity, we began to optimize whether the parts processed by plane laser can be transferred to other processes.

Fig. 1 Turret punch process equipment

Through the efficiency and cost calculation of the processing process, it is found that the parts with regular contour, complex inner cavity contour or porous are processed by plane laser.

Obviously, the preparation of the sheet metal process is not optimal and the processing cost is high;

The cutting machine is used for blanking, and then the turret punch is used to process the inner cavity contour, so the combined processing efficiency is very high and the cost is low.

At present, the parts with regular appearance contour and complex inner cavity contour are processed by cutting and turret punching, which has very high efficiency and flexibility and can meet the needs of production planning.

As a very successful case, a part on the cab has regular contour and large size.

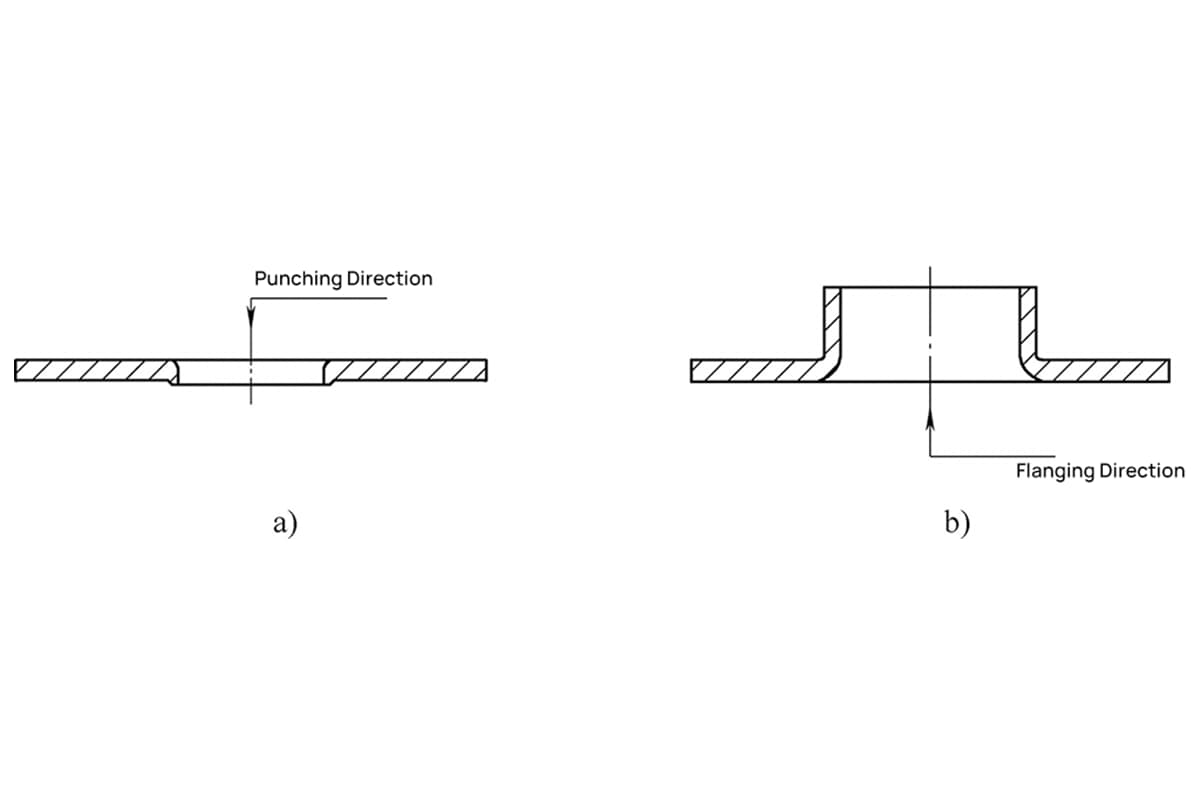

After cutting (Fig. 2), the NC punch is used to punch the inner contour (Fig. 3).

Using material preparation and blanking, the processing time of each piece is about 10s, while using plane laser cutting, the processing time of each piece is about 72s.

Using plane laser cutting has the consumption of auxiliary materials.

At the same time, the daily maintenance cost is much higher than that of an ordinary shearing machine.

Through comparison, it is found that this kind of part adopts the combined processing technology of material preparation and blanking and turret punching, which has high production efficiency and low production cost.

Fig. 2 Cutting and blanking

Fig. 3 Turret punching

With the diversified market demand, more and more orders and customized products, there are many different configurations of vehicles with the same horsepower, resulting in a variety of models with the same horsepower.

For many models in the cab and assembly, only the contour dimensions of the inner cavity are different and the contour is the same, so small batches and multi-variety parts cannot be produced on the punch.

At present, stamping processing is mostly carried out in large quantities, which has very high efficiency and low cost.

At present, the production mode of plane laser processing can only be used for this kind of small-batch and multi-variety parts.

The production efficiency of this kind of part is very low and the processing cost is high, but the customers will not pay for it.

They only pay for the stamping processing cost, and the excessive cost can only be amortized within the company.

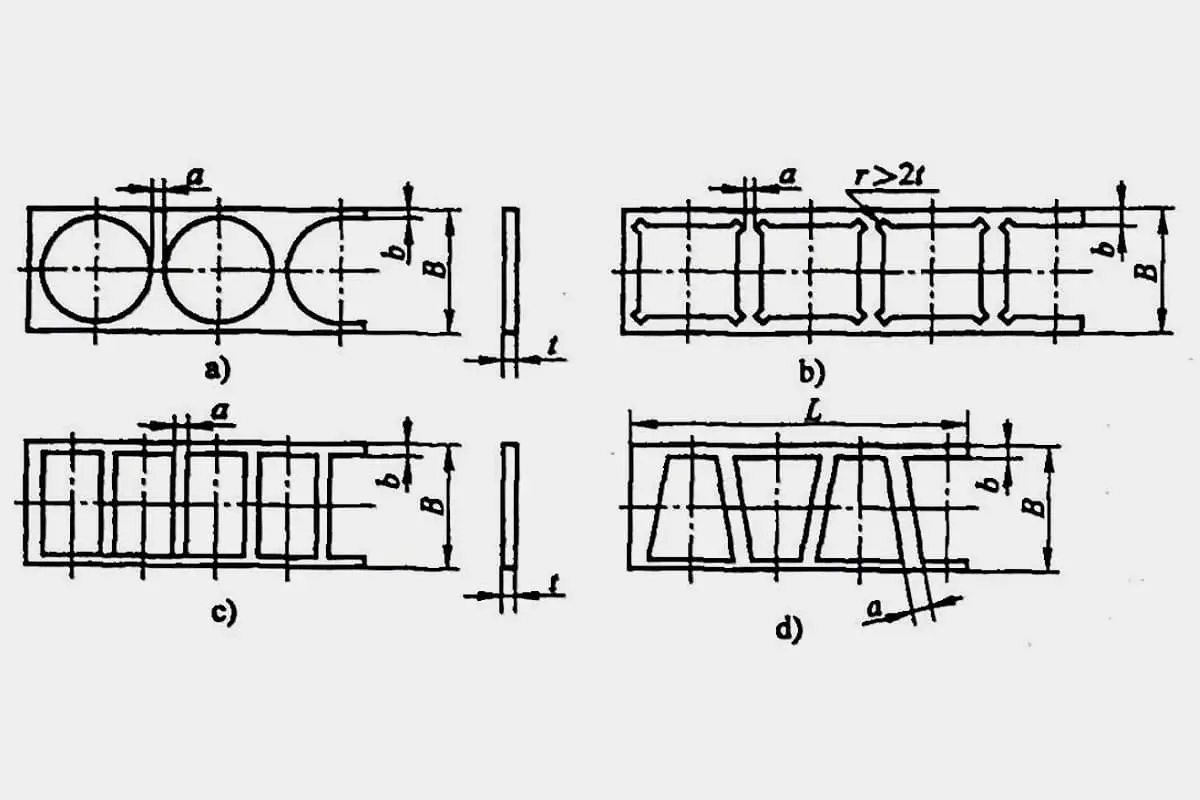

Through process research, sort out similar parts, classify the processing contents in the parts, and determine the basic parts, as shown in Fig. 4.

Fig. 4 A common part

The production method of the stamping process is adopted, and then the other internal contours required by each model are processed by turret stamping.

The plane laser cutting process is adopted in the trial production of new products of dense mesh plate parts, which can be delivered quickly, but the output of more than 20 units will seriously affect the production efficiency.

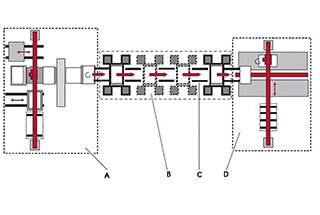

For example, for our protective plate parts (Fig. 5), due to the lack of an appropriate mesh plate purchased at first, plane laser cutting is used to ensure the delivery node in advance.

Using plane laser processing, each piece takes 30 minutes.

Fig. 5 Guard plate porous parts

With the continuous increase in the number of goods demanded in each batch, the trial production progress of other new products is seriously affected.

Finally, the turret punching die is customized, the plane laser cutting shape is adopted, and the turret punching process is used to process the internal dense holes.

After adopting the new combined process, it is estimated that the plane laser cutting contour takes 1 minute, the actual processing of 183 holes in the turret takes 2 minutes, and each piece takes only 3 minutes.

In the future, these kinds of similar parts with complex contours and dense inner cavity holes adopt the combination of plane laser and turret punch, which makes more effective use of the advantages of each machine tool, resulting in higher production efficiency and lower cost.

Through the research on some common problems in the actual production process of tractor panel, combined with the existing equipment resources, the combination of turret punching process and other processes is used to give full play to the processing advantages of each process and equipment, improve production efficiency and reduce production cost.

Only by continuously optimizing and improving the production process, solving the problems in actual production, avoiding building more inventory, and effectively dealing with various uncertainties brought by market changes can enterprises enhance their comprehensive competitiveness.