Imagine a machine that can revolutionize sheet metal processing, making tasks easier and more efficient. This article delves into the CNC panel bending machine, highlighting its advantages over traditional press brake machines. You’ll learn how this technology enhances bending accuracy, reduces labor demands, and minimizes surface scratches. By the end, you’ll understand why industries like switch cabinets and kitchen cabinets are rapidly adopting this innovative solution, and how it could significantly impact production efficiency and cost.

It is well-known that almost all sheet metal processing enterprises utilize sheet metal bending machines.

However, those who have experience operating press brake machines understand that regardless of whether it is an ordinary press brake or a CNC press brake, whether it involves large and heavy workpieces in the switch cabinet and elevator door industry or small workpieces in the kitchen utensils and air conditioning industry, and whether it involves workpieces primarily produced in batches or customized single workpieces, using a press brake machine can be both mentally and physically taxing.

As a result, in the current sheet metal processing industry, it is common for no one to want to be a press brake operator. Even when the role is offered as an apprenticeship and the enterprise provides higher wages than CNC punch technical workers, few individuals are willing to take on the job.

This has led to the emergence of CNC panel bending machines.

This post will analyze and introduce the CNC panel bending machine in reference to the press brake machine.

The CNC panel bending machine differs from the press brake machine in principle and provides superior assurance for bending accuracy and sheet protection. Additionally, tool replacement is more intelligent and convenient, and there is less demand for high operator proficiency.

The press brake adjusts the downward stroke of the top punch to control the bending angle.

During bending, the short side is on the inside, so the operator needs to support most of the material on the outside. Additionally, the operator needs to hold the plate during the bending process to follow its upward movement.

For bending large workpieces, it requires two or more employees.

If there are bending demands in different directions for all the bending processes of an edge, it’s necessary to manually flip the material repeatedly.

The panel bender works by placing the sheet on the worktable, fixing it with the edge press beam, and bending it by turning the beam up or down.

The panel bender eliminates the need for manual positioning, auxiliary positioning, and flipping in all the bending processes of one edge.

(1) Dimensional accuracy.

The precision of dimensions controlled by the press brake is the precision of the short side dimension of the backstop positioning. Once the bending process is completed, any errors are accumulated and carried forward to the next stage of bending, resulting in an accumulated error that is concentrated on the final forming dimension.

In contrast, the precision of dimensions controlled by the panel bender is based on the outside edge serving as the reference point for each folding operation. Any controlled dimension errors are only concentrated on the first fold, and this has no impact on other dimensions.

(2) Angle accuracy.

The bending angle on the press brake is determined by the downward stroke of the top punch, which is directly related to the material thickness.

On the other hand, the panel bender directly controls the bending angle, and the material thickness has minimal impact on it.

(3) Consistency.

The dimensional accuracy of each side of the press brake is ensured by the backstop positioning, but this accuracy can be inconsistent due to various external factors.

The angle of the workpiece is determined by the position of the ram. The accuracy of the ram control positioning and the temperature conditions of the hydraulic system have a significant impact on the angle precision.

The servo motor of the press brake controls both the positioning accuracy and angle processing of the workpiece, ensuring consistent size and angle processing.

During the operation of a press brake, the material moves relative to the plate, which can result in indentations if the plate surface is not protected. Additionally, when one side of a large workpiece requires multiple processing techniques or bends, it needs to be turned over and moved several times, which can lead to scratches.

However, when using a panel bender, there is no relative movement between the pressing beam die or bending beam die and the plate. As a result, surface scratches can be avoided.

Furthermore, when working with various processing techniques on one side or bending large workpieces, the sheet metal can be horizontally placed on the worktable for processing. After the first positioning, all the necessary processing can be completed on one side of the workpiece without having to move it around, completely avoiding surface scratches.

Since the bending die is used to create the fixed folding line and form the angle of the parts, it is necessary to change the tool or machine when bending various materials, thicknesses, angles, and even special structures.

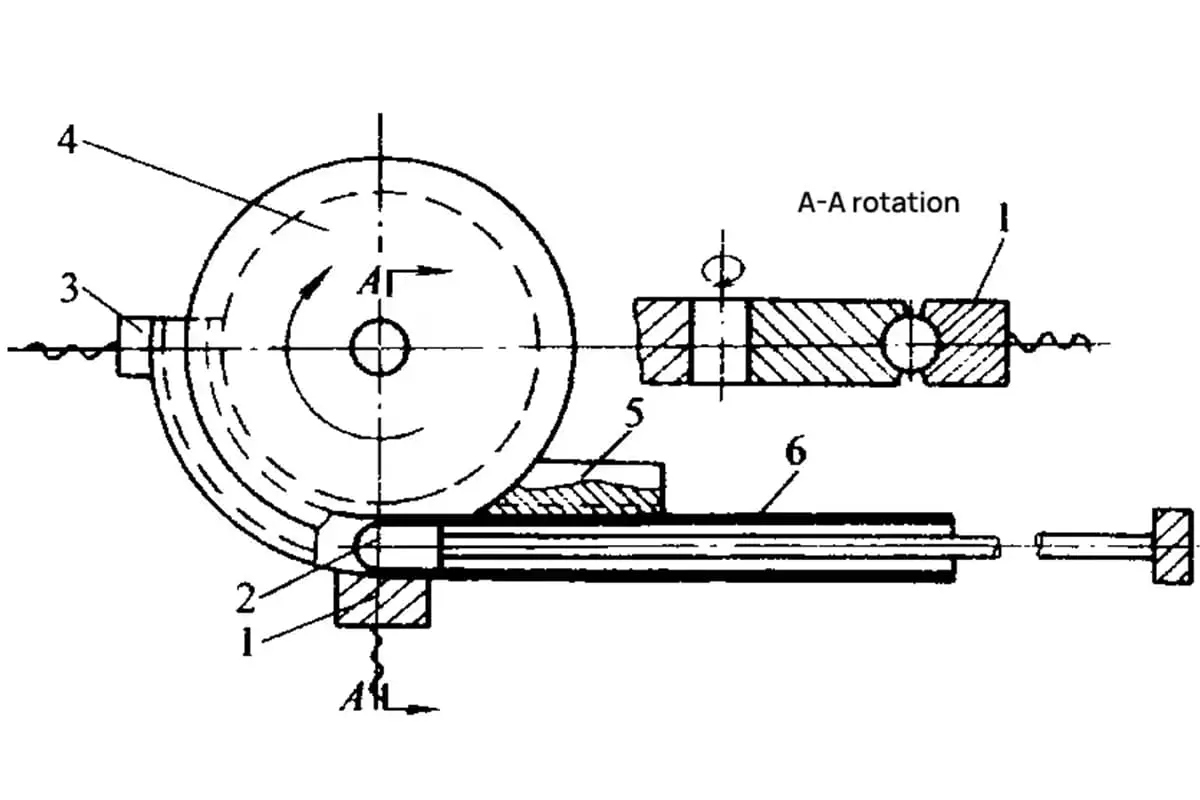

Moreover, when edging is required or when the bending process impacts the bending, multiple sets of dies with different lengths are necessary to complete the processing of the same workpiece (refer to Fig. 1).

In such cases, it is necessary to replace and readjust the mold, or even replace the machine tool.

Fig. 1 Bending workpiece affected by sequence

The panel bender utilizes two sets of molds to achieve the fixation of the bending line and angle forming, respectively. The spacing between the two sets of molds can be automatically adjusted to realize angle forming for various materials, plate thicknesses, and R angles.

To achieve hemming, bending with arbitrary angles, bending arcs, and other requirements, different control programs can be selected. The cooperation between the two sets of pressing and bending dies facilitates easy processing of the workpiece.

During the bending process, if the die length needs to be changed, the program can be adjusted at any time for automatic switching. There is no need for further debugging after the die replacement.

The programming and operation of a press brake require a high level of technical skill from bending workers, particularly for workpieces with complex folding processes.

The panel bender’s program can be developed offline using programming software. By importing 2D or 3D graphics and utilizing simple drag and drop settings, the machining code can be automatically generated.

During the programming process, the system can also provide automatic prompts for bending interference.

Once the program is transferred to the panel bending machine through a network cable or USB disk, operating the machine is a straightforward process of loading and unloading and pushing buttons.

Industries such as switch cabinets and elevator door panels with large and heavy workpieces, as well as those with small and light workpieces such as kitchen cabinets and air conditioners, are giving significant attention to panel bending machines.

According to preliminary statistics, the CNC panel bender has been widely applied in various industries, including switch cabinets, elevators, household appliances, kitchen cabinets, and medical equipment.

The following aims to share the advantages of using panel bending machines in the switch cabinet and cabinet industries, which are widely adopted.

Switchgear products (as shown in Figure 2) are characterized by their large size, heavy weight, and potential danger. Moreover, there are specific precision requirements for the final dimensions of the formed products.

Fig. 2 Switch cabinet parts

Using a conventional bending machine for processing requires at least two operators to handle the workpiece and bend the iron plate one by one according to the speed of the machine. This method places high demands on workers and can result in unstable error control. Additionally, the heavy workload significantly limits daily production capacity and poses significant security risks.

On the other hand, a panel bender requires only one person to operate, who can work in conjunction with automatic loading and unloading. The workpiece is placed flat on the working platform, and the machine automatically carries out edge-changing and folding processing. This process is not affected by human factors and results in precise bending without deviation.

In summary, the panel bending machine not only saves time and labor but is also safer and more efficient.

Cabinet products (Figure 3) is characterized by relatively thin sheet, but the processing requirements are more complex.

Fig. 3 Cabinet product parts

When using a press brake machine for bending, it is important to verify the unfolding size of the parts as per the drawing specifications. After ensuring that there are no errors, the appropriate tool needs to be selected for setting and matching, followed by programming as required.

This entire process demands a high level of work experience from the workers.

Moreover, for round edge wrapping and special processes, multiple sets of tools or machines need to be changed when using a press brake machine, making it a time-consuming and laborious task.

On the other hand, a panel bender simply requires the input of sheet metal size and forming size, and the programming software generates a rational folding program automatically.

The universal bending tool of the panel bender can save significant time by reducing or eliminating the need for changing bending tools. For kitchen utensils with several special process requirements, panel benders can easily complete the processing and fold the workpieces that meet requirements more quickly and economically.

With its automatic production capabilities throughout the entire process, the CNC panel bender offers several advantages over multiple sets of press brakes alone. It can also achieve automatic production when connected with punch presses, laser cutting machines, and other machine tools. Moreover, it can be used with intelligent management software and multi-row material warehouses, providing customers with a complete set of solutions for intelligent chemical plants.

In the face of the current challenges of “difficult employment” and “expensive employment,” an intelligent and efficient automatic production line can significantly reduce labor requirements and experience in production. Customers can achieve higher production capacity and income while minimizing labor costs.