What are the dangers when using various gases? What should I do in case of an emergency?

- Avoid having flammable and explosive materials near any cylinder.

- Stay clear of open flames and do not work with gas at temperatures above 60 degrees Celsius. Using gas from unapproved sources is strictly prohibited.

- The Dewar tank should not be tilted more than 45 degrees to prevent frostbite. Protective eyeglasses and gloves must be worn during operation. Venting with high gas concentrations is strictly prohibited. If the Dewar tank falls to the ground, it should be uprighted within two minutes.

- Secure the cylinder using a holder.

The main components of the laser cutting machine and their respective roles?

Laser Source: Generates the laser beam.

Laser Cutting Machine: Used for computer numerical control (CNC) machining.

Chiller: Cooling system for the laser beam, the reflective lens, and the cutting head.

Air Compressor: Supplies air for the laser cutting machine and auxiliary machining gases.

Dryer: Filters out water, oil, and other contaminants in the air to maintain dry air conditions.

Dust Collector: Removes dust and waste gases.

Regulator: Maintains a stable operating voltage for the device.

The meaning of the following code

| G00: | Rapid positioning | M00: | Unconditional suspension |

| G01: | Linear interpolation | M36: | Turn off followers |

| G02: | Clockwise circular interpolation | M31: | Choose air |

| G03: | Counterclockwise circular interpolation | M35: | Turn on followers |

| G04: | Pause | M10: | Open mechanical shutter |

| G10: | Empty stack | M30: | The program ends and returns to the program header |

| G50: | Scale by | M11: | Shut down mechanical shutter |

| G09: | Program read-ahead | M06: | Shut down electronic shutter |

| G51: | Workpiece rotation | M07: | Turn on electronic shutter |

| G71: | Metric programming | M14: | Turn off the auxiliary gas |

| G91: | Incremental programming | ||

| G90: | Absolute coordinates |

Why recalibrate when changing different cutting materials and different types of nozzles? What should you do if the automatic calibration is not successful?

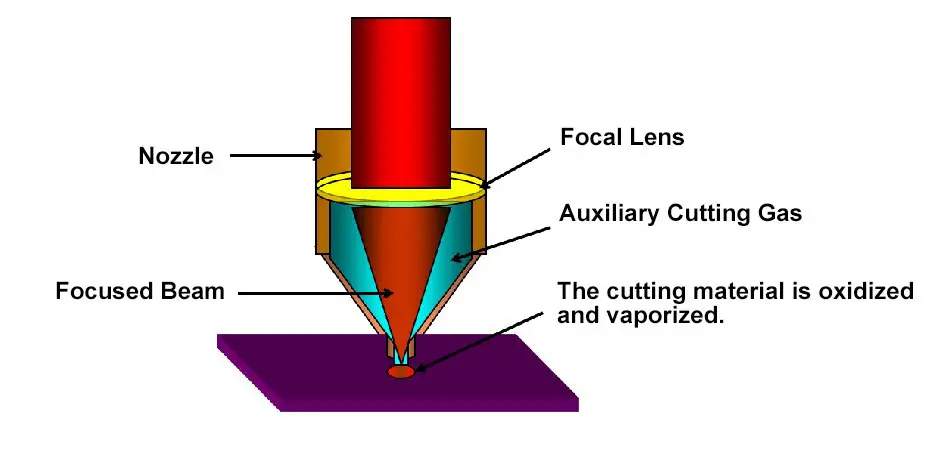

The height is monitored using a capacitive sensor, which is influenced by the material, the surface area in contact, and the distance between the sensor and the material.

Different nozzles have varying contact areas, so changing nozzle types requires re-calibration.

If automatic calibration fails, perform manual calibration by executing the M70 command in manual data input (MDI) mode, or switch to manual calibration.

External light path and Z-axis coaxial adjustment method

The X-axis is adjusted by turning the upper and lower left and right adjustment screws on the laser bracket. The Y-axis and Z-axis are adjusted using three adjustment nuts on the lens holder.

Typically, rough adjustments are made using a red light, followed by fine adjustments using a cross light fork, to ensure that the front and rear spots are centered.

Method and precautions for finding focus

To prepare the flat board, place it at the end of the laser cutting machine at an angle of 30-45 degrees.

Next, remove the nozzle and adjust the scale to -5. Set the piercing delay (P199) to 0 and move the cutting head to the highest point of the board.

Bring up the program to focus the laser, manually turn on the air, and run the program. Find the spot where the burn marks on the board are the thinnest and then install the nozzle. Move the cutting head manually above this thinnest spot.

Then, unscrew the scale until the nozzle is 0.5 mm away from the surface of the plate. Record the scale value at this point, which is referred to as the “zero focus scale.”

Precautions:

Before executing the program, it’s important to verify that the direction of movement of the focus adjustment in the program matches the orientation of the board to avoid any reverse collisions.

It’s also essential to manually turn on the air before and after executing the program to prevent smoke from affecting the lens.

Once the program has finished, it’s crucial to avoid moving the Z axis until the focus has been re-established, and the board must not be bumped or jostled.

Write a coaxial program and say the meaning of each sentence

| % | Program header |

| P900002 | Program name |

| N1010 | Program annotation |

| N1020M10 | Turn on mechanical shutter |

| N1030M21 | Select laser pulse frequency |

| N1040M15 | Select continuous wave mode |

| N1040G4F30 | Pause 0.03 seconds |

| N1050G111V100 | Laser power |

| N1060U1 | Determine power |

| N1070M91 | Cancel laser open limit |

| N1080M7 | Open electronic shutter |

| N1090G4F10 | Pause 0.01 seconds |

| N1100M6 | Electronic shutter |

| N1110U0 | Cancel set power |

| N1120M11 | Turn off mechanical shutter |

| N1130M30 | The program ends and returns to the program header |

What are the factors that affect laser cutting?

1) Beam quality:

- Beam wavelength

- Power

- Energy

- Mode

- Beam angle

- Polarization state

- Beam position

- Stability

- Pulse width and peak power

- Repeat frequency

- Average output power

2) Process parameters:

- Speed

- Power

- Air pressure

- Cutting height

- Focus position

- Nozzle size and roundness

3) External light path:

- How good is the focusing mirror?

- Degree of contamination of circular polarizers and reflector

4) External conditions:

- Gas purity

- Sheet quality

What kinds of gases that is needed for the laser to work? What is the purity of each? What is the external minimum pressure?

| ROFIN: | High purity nitrogen 99.999% 5bar

Mixed gas (carbon dioxide, helium, nitrogen, carbon monoxide, oxygen, helium), designated supplier |

|---|---|

| PRC | High purity nitrogen 99.999% 5bar

High purity carbon dioxide 99.999% 5bar Pure nitrogen 99.995% 5bar |

| TK | High purity nitrogen 99.999% 5bar

High purity carbon dioxide 99.999% 5bar Note: The gas blown by the TK laser is shunted by high-purity nitrogen inside the laser. |

Precautions before executing the program? And what should you pay attention to during processing?

Before starting the machining process, it’s important to verify that the selection procedure is correct, the process parameters have been correctly named, the external auxiliary gas is available, and the position of the plate is accurate.

To prevent deformation of the sheet during machining, which could result in collisions, it’s crucial to avoid any disturbances. When the machine is in operation, the operator should remain attentive and not leave the machine, ensuring their personal safety at all times.

What are the several types of lenses that are used on the machine?

Focusing mirror, circular polarizer, round reflect mirror.

Stainless steel hanging slag, why can’t it be cut through and how to solve it?

There are two types of slag that can appear on the lower surface of the cut material:

- Hard hanging slag: This can usually be resolved by lowering the focus or increasing the air pressure.

- Soft hanging slag: This can typically be addressed by increasing the cutting speed, reducing the power, and raising the focus position.

If the material is not cutting through, the solution is generally to slow down the speed, increase the power, and adjust the focus position.

What is the relationship between the diameter of the cutting hole and the thickness of the plate? If it is out of range, what should be done?

For Carbon Steel: The hole diameter should not be less than the plate thickness if it’s below 8mm. If the hole diameter is above 10mm, it should not be less than 1.2 times the thickness of the plate.

For Stainless Steel: The hole diameter should not be less than the thickness of the plate if it’s below 4mm. If the hole diameter is above 5mm, it should not be less than 1.5 times the thickness of the plate.

If the holes exceed these requirements, they can be drilled using marking positioning or pulse slow cutting techniques.

Sudden power outage during processing, how should we continue laser processing?

If the machine is powered off during the machining process, the following steps should be taken after restarting the machine:

- Return the machine to the reference point to re-establish the machine coordinate system.

- Open the NC program that was being executed before the power was turned off and check if the Q999997 subroutine (which calls the workpiece coordinate system memory) has been called. If it’s not called, the workpiece zero point can only be located manually.

- If the Q999997 subroutine has been called, select the workpiece coordinate system using G54.

- Move to X0Y0 to find the workpiece zero point using G00X0Y0.

- Check the values of parameters P8 (the program line number being executed before the power was turned off) and P12 (the last line number of G00 fast positioning before the power was turned off) in the loop parameter. Use FASTPLOT to check the program and verify that the program number is correct.

- Modify the NC program by adding an unconditional pause (M00) after the G09 (read ahead of time, pre-stage function) command and increasing the skip command (GO**** with a value for P12 memory). After the memory G00 command line at P12, add the cutting layer process subroutine, such as Q990051 (first layer cutting parameter call).

- Execute the program, turn on the auxiliary function and laser power, and resume cutting with automatic positioning.

What are the specific reasons for focusing lens contamination?

Air or auxiliary gases such as oxygen and nitrogen are not pure and contain contaminants such as moisture, particles, soot, and oil.

The exterior light path is also not clean and can become contaminated with slag during the cutting and perforation processes.

Which materials cannot be processed with a laser?

Gold, silver, copper, pure aluminum, hard alloy steel, marble, cast iron, glass, etc.

How many perforate methods are there? Under what circumstances is each method used? What is the cause of burst holes when using ordinary perforation method? How to deal with it?

There are three methods of perforation:

- Conventional perforation

- Progressive perforation

- Burst hole

Typically, conventional perforation is used on carbon steel plates that are 10mm or less in thickness, while progressive perforation is used on carbon steel plates that are 10mm or thicker. The use of burst holes is not common.

Please note that aluminum alloys should not be perforated using progressive perforation, but rather should be perforated at the focal point.

Reasons for using a burst hole include:

- Insufficient piercing time

- Excessive perforation pressure

- High perforation focus.

What are the reasons for the inconsistent cutting end faces?

- Coaxial misalignment

- Incorrect light path

- No nozzle

- Bad quality plate

- Focusing mirror pollution

- The start cutting surface is not good

- Light opening delay

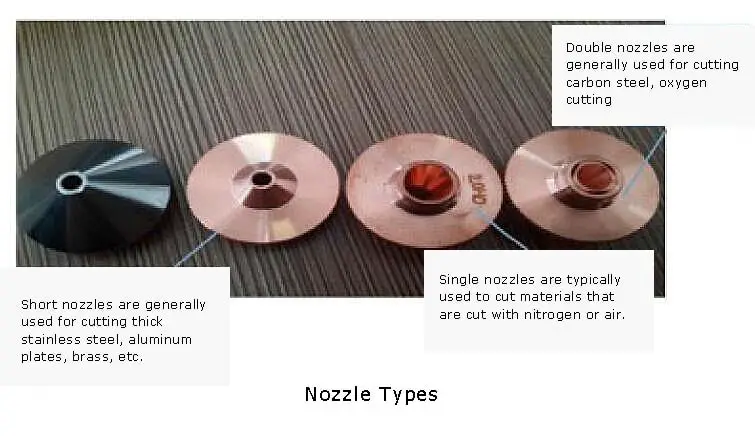

What are the types and sizes of nozzles? How should nozzles be selected for different thicknesses of materials?

There are two types of nozzles: double-layer high nozzles and single-layer straight-bottom low nozzles. The double-layer high nozzles come in sizes 1.4, 2, 2.5, and 3.0, while the single-layer straight-bottom low nozzles come in sizes 1.5, 2.0, 2.5, and 3.0.

Typically, carbon steel uses double-layer high nozzles. For thicknesses of 8mm or less, a 1.4 nozzle is used; for thicknesses between 10-12mm, a 2.0 nozzle is used; for thicknesses between 14-18mm, a 2.5 nozzle is used; and for thicknesses between 20-25mm, a 3.0 nozzle is used.

Stainless steel and aluminum alloys, on the other hand, generally use a single-layer straight-bottom low nozzle.

Detailed processing parameters of oxygen cutting 10mm-16mm carbon steel and nitrogen cutting 8mm stainless steel

| Laser Generator Type | Sheet | Power | Speed | Focus | Nozzle Dia. | Cutting Height | Cutting Gas | Air Pressure | Lens |

| mm | W | mm/min | mm | mm | mm | Bar | inch | ||

| TK2000 | MS 10 | 1800 | 1000-1200 | 1 | 2 | 1.2 | O2 | 0.8~1.0 | 7.5 |

| PRC4000 | MS 16 | 2450 | 800-1000 | 2 | 2.5 | 1.2 | O2 | 0.6~0.7 | 7.5 |

| ROFIN DC030 | SUS 8 | 2950 | 800-1100 | -8 | 2.5 | 0.65 | O2 | 20 | 7.5 |

What are the advantages of 21.5-inch and 7.5-inch lenses when cutting sheets?

5-inch lens:

This lens is ideal for cutting thin plates as it offers fast cutting speed and high-quality results.

7.5-inch lens:

This lens is suitable for cutting thick plates due to its small taper and high-quality cutting results. It is also effective in protecting the lens from damage.

What is the difference between the far end and the near end of the optical path in the focus, why is there such a difference? How to solve the impact of its cutting?

The focus at the distal end of the optical path is lower compared to the focus at the proximal end due to the divergence angle of the laser light, which is not perfectly parallel.

To counteract the effect of different focus during the cutting process, the height of the operation panel can be adjusted by turning the adjustment knob or by adjusting the cutting speed override.

What should you pay attention to when cutting non-metal?

It is imperative to avoid cutting with oxygen and to instead use either nitrogen or air.

To prevent collisions and lens contamination, the distance between the nozzle and the material should be increased, and a small gap should be maintained to prevent dust buildup.

How to prevent the workpiece from deforming and turning during the cutting process? What are the causes of the dimensional deviation of the cut workpiece?

To prevent deformation and warping during cutting, techniques such as misalignment cutting, micro-connection, and shifting the cutting point can be employed.

If the size of the workpiece deviates too much due to displacement caused by deformation, it may result in a significant deviation from the desired size.

Why cut a small round when cutting stainless steel over 4mm, or start with a slow cutting?

It is important to ensure that the auxiliary airflow is directed downwards at the start of the cutting process in order to effectively prevent the reversal of slag.

What kind of gas is used to cut carbon, what effect does gas purity have on cutting?

Oxygen is commonly used as the cutting gas and its purity is typically 99.5% or higher.

The cutting quality improves with higher oxygen purity.

What kind of gas is used to cut stainless steel, and what effect does gas purity have on cutting?

Nitrogen is usually used as the cutting gas and its purity is usually 99.6% or higher. If the nitrogen purity is low, the cutting edge may appear yellow. On the other hand, if the nitrogen purity is high, the cutting edge will be brighter.

In addition, using high-purity nitrogen can also reduce the buildup of dross at the bottom edge of the cut.

When cutting stainless steel with film, face up or down? Why do this? What should you pay attention to with film cutting?

When the film is facing downwards, it hinders the discharge of slag, so the film should face upwards.

When cutting with a film, it is important to be mindful of the film peeling off and potentially snagging the cutting head. A common solution is to first make a mark on the film and then proceed with the cutting process.

What should you pay attention to when installing FASTCAM?

Once the installation is completed, replace the incorrect configuration files PA8000.com and SETUP.DAT in the FASTCAM installation directory with the correct ones.

What are the requirements for the incoming line for the stainless steel/carbon steel with different thicknesses?

For stainless steel that is 3mm or less in thickness, straight leads can be used. When cutting stainless steel that is 4mm or thicker, a combination of straight lines and small arcs is generally used.

For carbon steel, a circular arc is typically used.

What should be done if there is a sudden occurrence of a bad phenomenon during normal processing?

If an undesirable phenomenon occurs, it is important to first pause and then analyze the cause before taking appropriate action to address it.

What are the advantages and disadvantages of using bottled gas, dewar tank, and storage tanks?

Use Bottled Gas:

While the pressure is well-guaranteed, the high cost and short usage time necessitates frequent gas changes.

Use Dewar Tank:

With easy ventilation, a long service life, and a low cost, Dewar tanks are suitable for long-term processing. (It is recommended to use high-pressure Dewar tanks, with a gasification gas volume of generally not less than 80 cubic meters.)

Use Storage Tank:

Storage tanks offer significant gas savings and a low cost, with a long-lasting usage time. Typically, liquid nitrogen is charged once every half a month, making it a one-time investment. It is recommended for use when two machines are in operation and a large amount of nitrogen is needed for auxiliary processing gas.

What are the steps in programming in FASTCAM and FASTNEST?

The programming steps for FASTCAM are as follows:

- Import the DXF/DWG file and perform CAD clean-up and compression processing.

- Set the processing process and process settings, including tool compensation.

- Generate the program, specify the origin, and perform program verification.

The programming steps for FASTNEST are as follows:

- Set the plate size and modify the machine parameters, including the file type and FASTPATH.

- Add the processed workpiece pattern to the discharge table and set the number of workpieces.

- Click on automatic nesting and perform fine adjustments, if necessary, through manual adjustment.

- Verify the output program simultaneously.

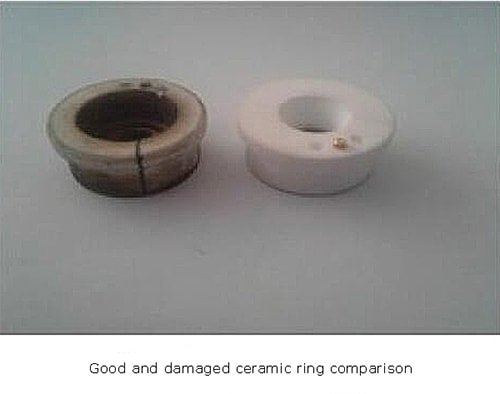

The meaning of “CUTTING HEAD NOZZLE LOSE” , the reason and solution for this alarm?

- The cutting head sensor nozzle loses alarm;

- Check if the nozzle is off;

- Whether the ceramic ring is intact;

- Whether the calibration is correct.

What is the meaning of EX CHANGE TABLE ALARM and how to solve this alarm?

Check if the cutting head is raised to the highest point in case of a failure in the exchange workbench.

What is the meaning and solution of AXIS Z MINUS LIMIT ALARM?

Z-axis negative hardware limit fault detected. To resolve this issue, press the emergency stop button, unscrew the cutting head from the hard limit switch, and then return to the zero position.

How to protect the ceramic ring from damage?

Please ensure that the cooling ceramic ring gas is functioning properly. The operator should not step away from the machine while it is in operation and should be vigilant for sudden release of plate stress and workpiece flipping. If necessary, prompt action should be taken after pausing the machine to prevent damage to the ceramic rings and cutting heads.

It is strictly prohibited to use double-layer high nozzles when cutting stainless steel or aluminum alloy with high-pressure nitrogen.

What are the reasons for the slag on the lower surface of the carbon steel plate?

- Incorrect Focus Position

- Low Air Pressure

- Contaminants on Sheet Surface (such as rust, oil, and glue)